Engine repairs are one of the most expensive costs associated with car ownership. If the engine, transmission or body is shot, those repairs can easily overwhelm your customers’ budgets. Engine sludge is a key contributor to engine failure; here’s how to recognize and prevent the problem before it becomes an issue.

What Is Sludge?

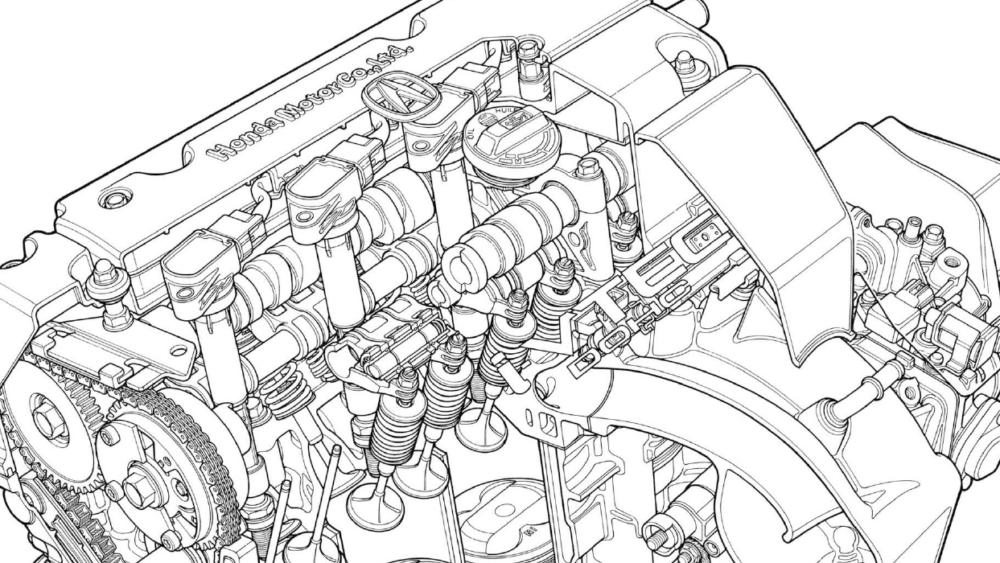

Sludge forms as motor oil oxidizes and breaks down, leaving behind deposits recognized as sludge. Sludge also forms due to moisture build-up and a lack of adequate positive crankcase ventilation (PCV). This glutinous muck is known to impede important oil pathways, including oil flow and return passages as well as filter elements. Engine sludge can even lead to severe damage necessitating complete engine replacement.

Can Sludge Be Prevented?

BMW M Power Engine sludge can usually be avoided by following the manufacturer’s motor oil change guidelines. Most owners may follow a normal schedule requiring oil change intervals of 5,000 or 7,500+ miles. However, if your customers operate their cars in extreme conditions, such as city driving or off-road use, then follow the extreme-duty schedule. This typically means oil changes once every 3,000 miles.

Who Should Be Concerned?

Any changes in engine performance should be of concern. A key symptom is an engine that has difficulty turning over. As long as the starter and all electrical connections are fine, spark should ignite promptly. You may also observe problems when checking the oil. Pull out the dipstick and if you notice globs of gelatinous material adhering to the stick, then sludge is likely present.

Is It Too Late to Fix?

Signs of engine sludge should serve as a red warning flag for vehicle owners. Once sludge has been detected, it can be difficult to remove. Depending on sludge severity, the fix here may involve using a product such as a fuel system additive and synthetic motor oil designed to combat three areas of engine stress: heat, deposits and wear. In more severe cases, the engine will have to be disassembled and special tools will need to be used to remove sludge. This repair won’t be inexpensive, but it can be better for your customers than paying thousands of dollars for a new engine.

Are Certain Engines More Susceptible to Sludge?

Simply because you carefully follow the manufacturer’s instructions doesn’t mean engine sludge build-up won’t happen. Indeed, in the early 2000s, certain engines from manufacturers such as Chrysler, Toyota and Volkswagen were disposed to sludge accumulation for various reasons, resulting in engine failure. Take note of recalls and service bulletins related to specific models and have all repairs handled immediately.

Be Careful With Used

In the case of new cars, follow the manufacturer’s maintenance schedule to keep things running smoothly. If you’re working on used vehicles, take a look under the hood. A burnt oil smell is a sign of a possible problem. With the engine off, remove the oil cap. Excess black deposits under the cap point to poor maintenance. Lastly, take note of the vehicle warning lights. If the check engine light is illuminated, it may mean that the gas cap is loose, damaged or missing. On the other hand, it could point to more serious problems such as an oxygen sensor, mass airflow sensor, spark plugs or plug wires that need replacement.

Courtesy of NAPA KNOW HOW.