Nothing is worse than a drivability issue with no codes. The problem could be poor fuel economy, stumbling or idle quality. The owner might know something is not correct. You might have been able to replicate the issue on the test drive. But, there are zero codes. Where do you start? Misfire monitors and fuel trims.

No code diagnostics are some of the most challenging drivability issues. Remember, an engine management system can make many adjustments to minimize the effects of suboptimal air, fuel or spark. Thinks of it as an adaptive immune system able to protect the engine and emissions. But, your diagnostic nightmare might not be to the point why it is setting codes.

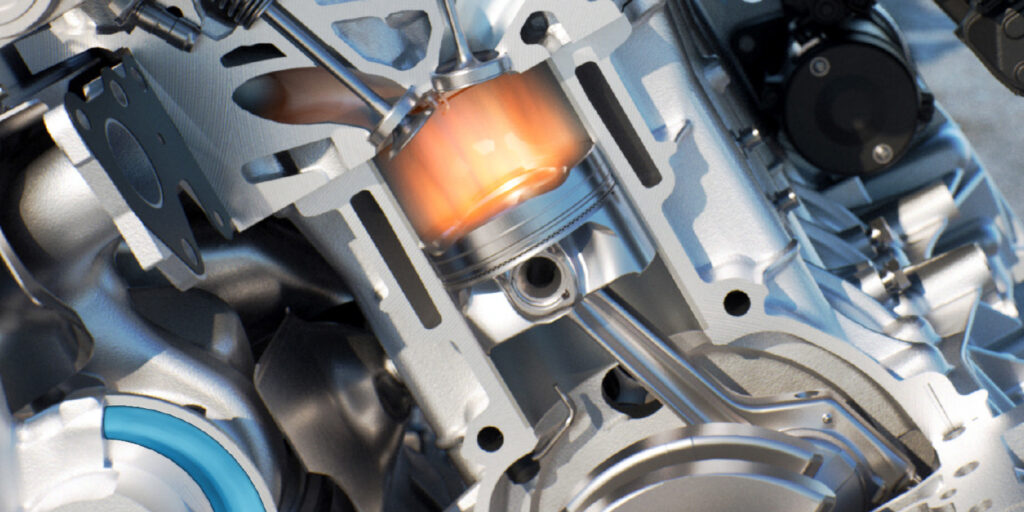

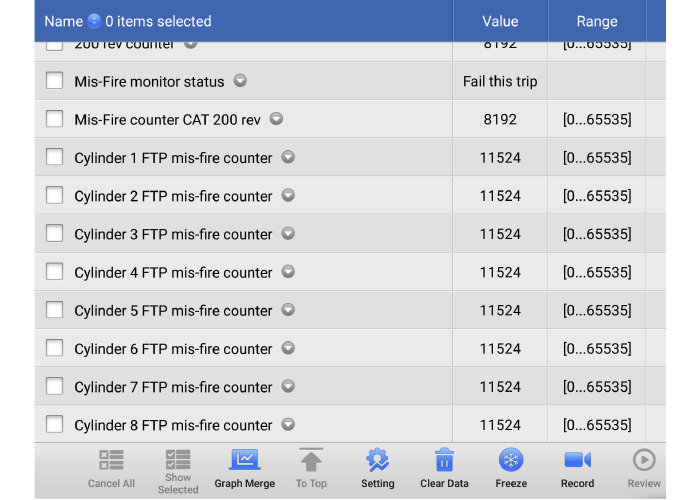

The first piece of data you need to look at is the misfire monitor. You can look at these and confirm if it is a multiple or specific cylinder problem. You might think if an engine is misfiring, it must have codes! This is not the case. A misfire might not be a violent event. It could be an absence of combustion or something that occurs too soon or too late. Also, misfires can happen under specific conditions and idling in your bay is not one of them.

An engine might not misfire when at idle, but under load above 2,000 rpm, it might have misfires. For a misfire to set a code, it must pass a threshold over a set number of engine revolutions. If an ECM requires 150 misfires to set a code, 149 misfires will not set a code. But, you can still see the 149 misfires using a scan tool and misfire monitor.

The other piece of information you can use to diagnose a no-code issue is the fuel trims. Just like the misfire monitor, you can find the fuel trims in the generic or global data for most vehicles. Fuel trim information can also be found in the manufacturer-specific data stream items.

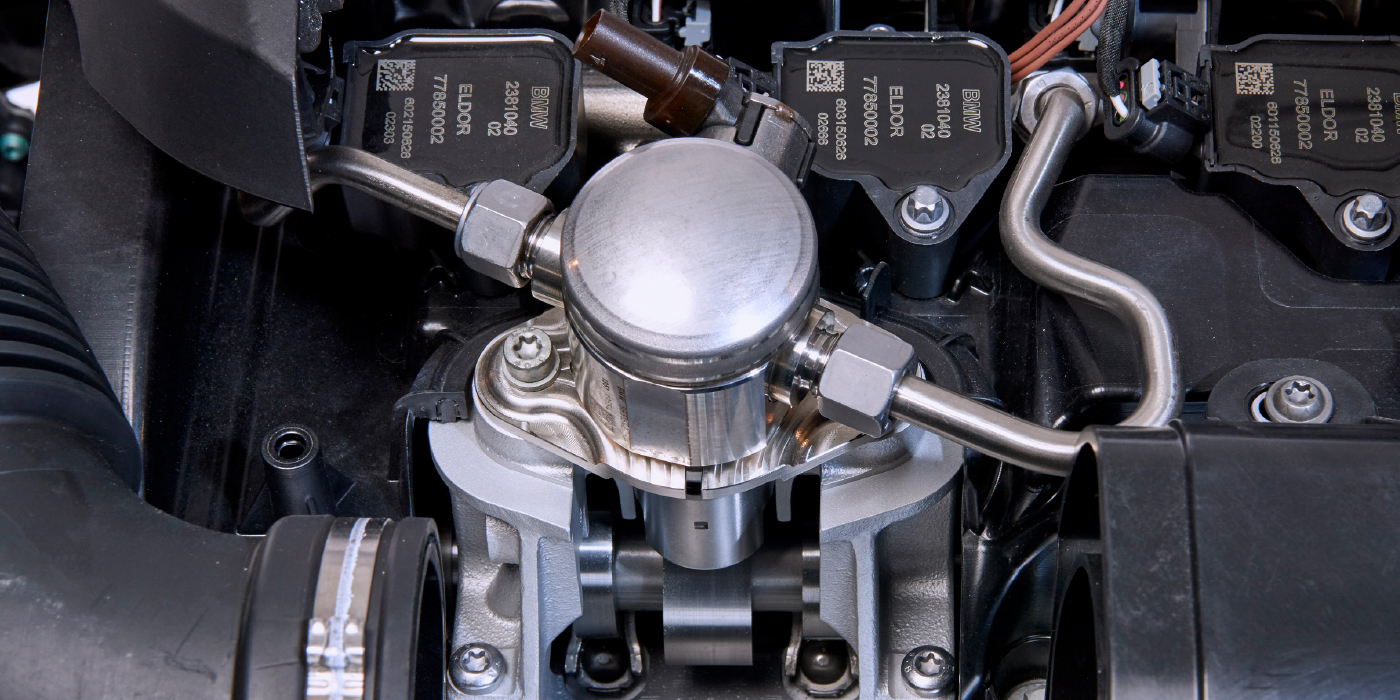

A modern engine measures two things exceptionally well: the amount of air going into the combustion chamber with the mass airflow (MAF) sensor and the byproducts generated by the combustion event with the oxygen sensor. These measurements allow the engine’s computer to put the right amount of fuel into the cylinder for the most efficient and cleanest combustion event.

The fuel trim is a constantly changing equation of throttle angles, loads and temperatures. These inputs can change the length of the fuel injector’s pulse and when the ECM sends power to the primary side of the coil. These can be called short-term factors for the fuel management of the engine.

The ECM does not perform a fresh calculation every time it fires an injector. It looks at the trends of the fuel trims. It is constantly compiling the data to arrive at the long-term fuel trims. This helps to make short-term corrections faster and estimate the fuel trim when the oxygen sensors are not up to temperature in open-loop operation.

Fuel trim is the adjustment the engine computer makes to the fuel mixture to maintain a balanced air/fuel ratio. Either the engine is taking away fuel or adding fuel so the exhaust byproducts, measured by the oxygen sensor, add up to an efficient operation. A positive number means the fuel system adds fuel by lengthening the injector pulse, so more fuel goes into the combustion chamber. A negative number means the engine is taking fuel away by shortening the injector pulse.

A rich fuel mixture can produce more power (up to a point), but it also increases fuel consumption and emissions. Conversely, a lean fuel mixture reduces fuel consumption but can also increase emissions if the mixture is so lean that it fails to ignite and causes a lean misfire.

Accurate fuel trim values require an accurate feedback signal from the oxygen sensor; otherwise the engine computer has no way of knowing whether the fuel mixture is running rich or lean. When the engine is shut off, the fuel trim values are retained in the computer’s memory, so the next time the vehicle is driven, it can pick up where it left off. Erasing the computer’s memory with a scan tool or disconnecting the battery or the PCM power supply to clear codes also wipes the fuel trim values, which means the computer has to start learning the fuel adjustments all over again the next time the engine runs.

In this article and online, you may hear about negative and positive fuel trims. If a fuel trim is positive, it means the injectors are adding more fuel to reach a balanced combustion event. A negative fuel trim means fuel is being taken away.

On most vehicles, the fuel trim is expressed as a positive or negative number. A “0” fuel trim would be a perfect air/fuel ratio achieved close to sea level. A positive number means it is adding fuel. A negative number means it is taking away fuel. In some cases, it is a number that could indicate a percentage.

Some vehicles use a scale for the fuel trims. 128 is zero. 129 and higher is lean, 127 and lower is too rich. Some vehicles might use a different middle point number; look at the service information to interpret these numbers.

What is a Short-Term Fuel Trim?

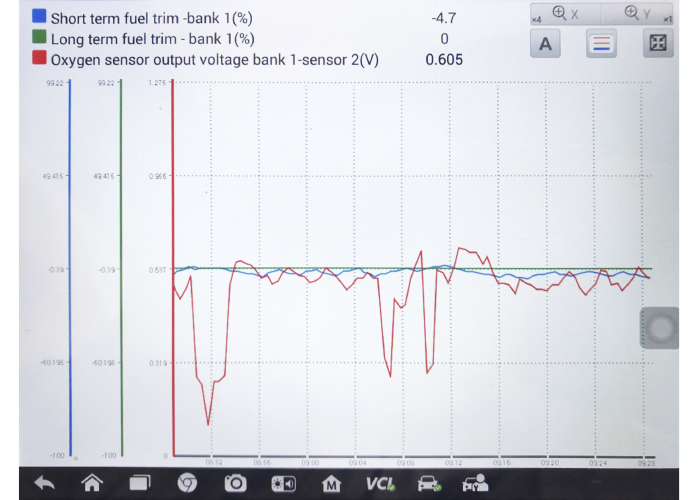

If you graph out the short-term fuel trims (STFT) using a scan tool, they will jump all over the place. As loads are put on the engine, the (STFT) numbers increase or go more positive. If the driver goes off the throttle and brakes, the STFT will go negative as fuel is taken away. Other events can change the short-term fuel trim, like the A/C compressor engaging.

What is a Long-Term Fuel Trim?

A long-term fuel trim (LTFT) changes slowly compared to the STFT. It can take five to 20 seconds for LTFT numbers to change on your scan tool. The LTFT number is computed using a monitor that samples the readings from the engine sensors over a set number of engine revolutions, drive cycles and other factors.

The LTFT drives the STFT, or if the engine is in normal and open-loop operation. By looking at the trends, it can get the fuel trim close. It is up to the STFT to make the final refinements.

Values for LTFT normally range from -10% to +10%. This value is a more accurate indicator of how the fuel mixture is being corrected to compensate for changes in the air/fuel ratio occurring inside the engine. If the number exceeds ±10%, it will set a code for a bank being rich or lean on most vehicles.

Application

The first thing to remember about using misfire monitors and fuel trims for no-code diagnostics is the information from the sensors has to be accurate. If the oxygen sensor is lazy or the mass airflow sensor is not responsive, it can make you chase your tail.

When tackling a problem make sure the engine is warmed up and in closed loop operation. Closed loop refers to the operational status of the oxygen sensor(s). If the oxygen sensor has not risen to operating temperature, the vehicle is said to be in “open loop” and in turn will use a set of preprogrammed instructions (fuel maps) to determine fuel delivery. Once the oxygen sensor is “live,” the fuel monitor is given the green light to use the oxygen signal to adjust fuel delivery. This is referred to as “closed loop operation.” Only during closed loop operation can short and long term fuel trims be used to diagnose emissions concerns.

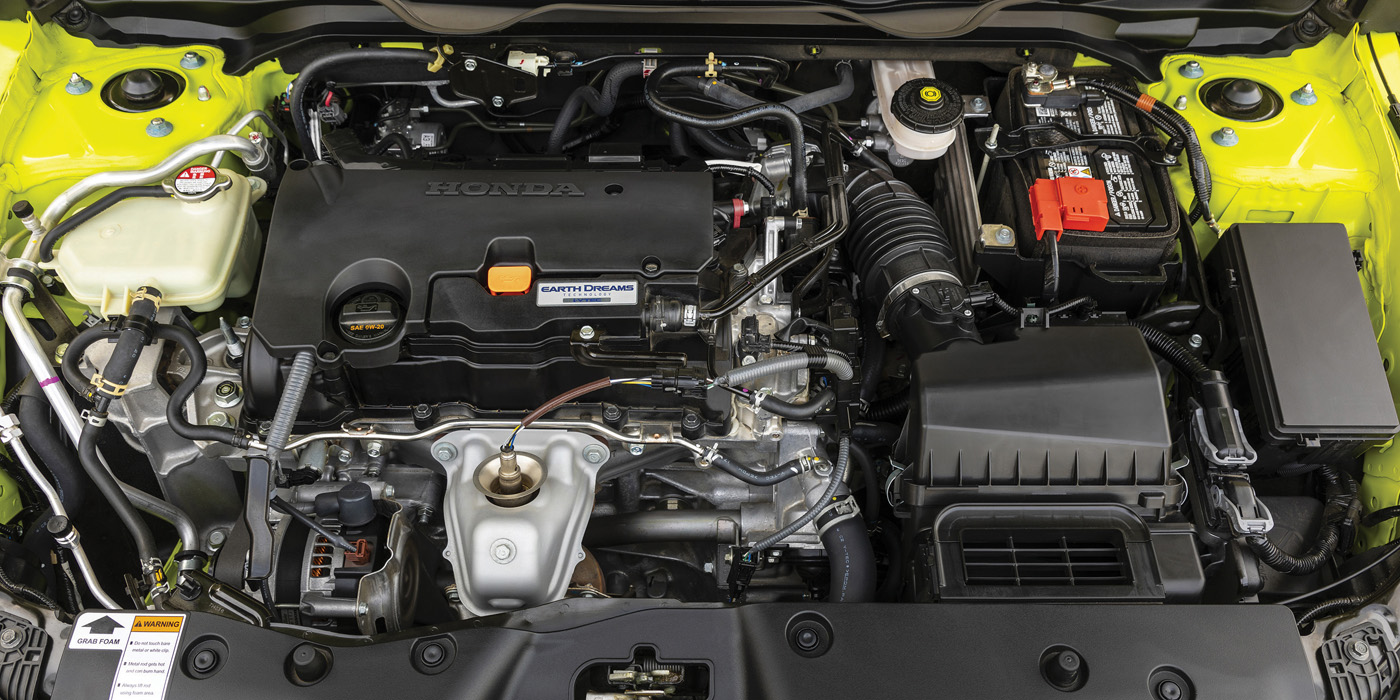

The second step is to inspect under the hood. The leading cause of positive fuel trims is vacuum leaks that adds extra unmetered air. Maintenance items like a clogged air filter can cause negative fuel trims. Visual inspection is the first step in diagnosing fuel trim problem. Disconnected vacuum hoses or a damaged air filter housing can change the fuel trims. Also, a clogged air filter can change the fuel trim percentages.

A common problem with some engines is the air temperature sensor. When these fail, they will show an extremely cold reading that will cause the long-term fuel tirm to be positive.

The performance of the oxygen sensors can be measured using a scan tool, a DVOM or a labscope. Check to see if the oxygen sensor responds correctly to rich and lean fuel conditions. A rich condition can be temporarily created with a propane enrichment tool and a lean condition can be temporarily created by removing a vacuum line. If the engine control system is in closed loop (check loop status with the scan tool), monitor the injector pulse-width changes in response to changes to the oxygen sensor readings. If these values are normal, you can assume the feedback fuel control system is doing its job.

Another strategy is to let the LTFT self-correct after the repair. Clearing the LTFT by disconnecting the battery will not confirm the original problem was corrected.