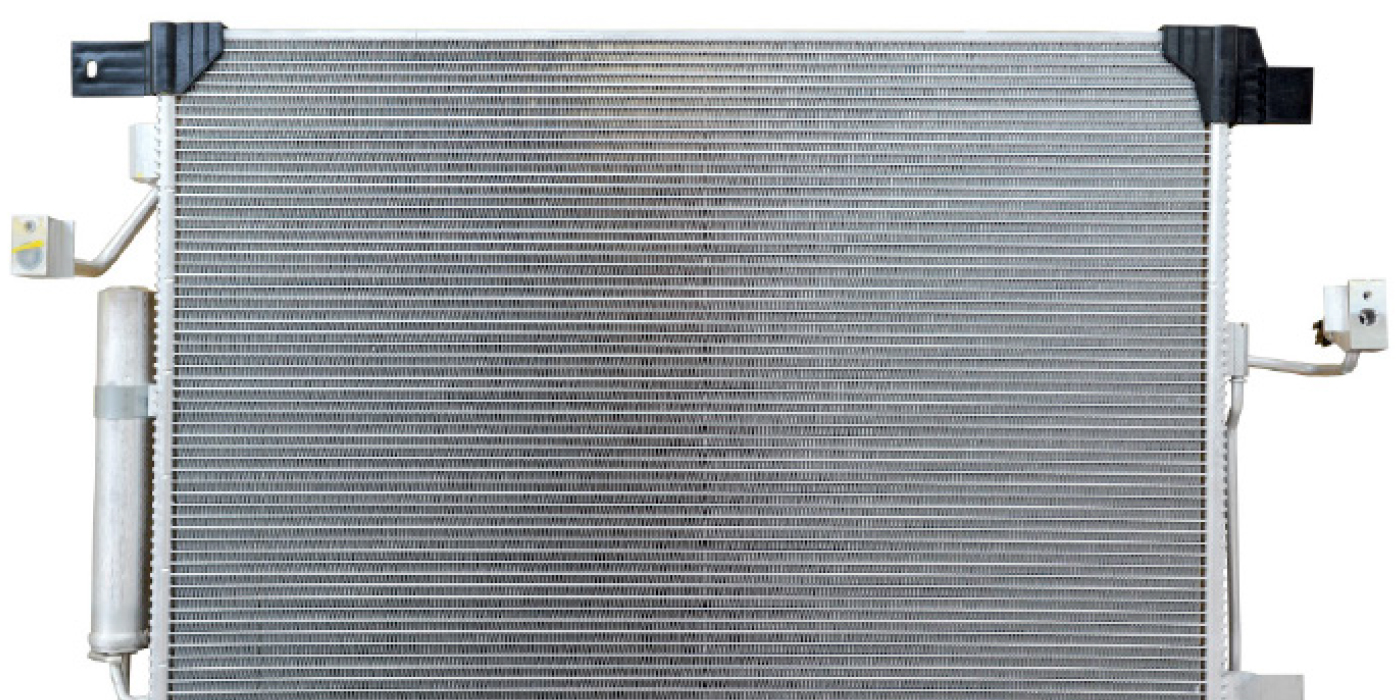

Better evaporators, condensers and compressors have allowed systems to do more cooling with less refrigerant.

When we look at the refrigerant demands on older R-12 vehicles, A/C systems operated on as much as 55 to 60 ounces. In contrast, R134-a systems have 12 to 16 ounces of refrigerant to deal with. Now, what are the changes? What are the differences there?

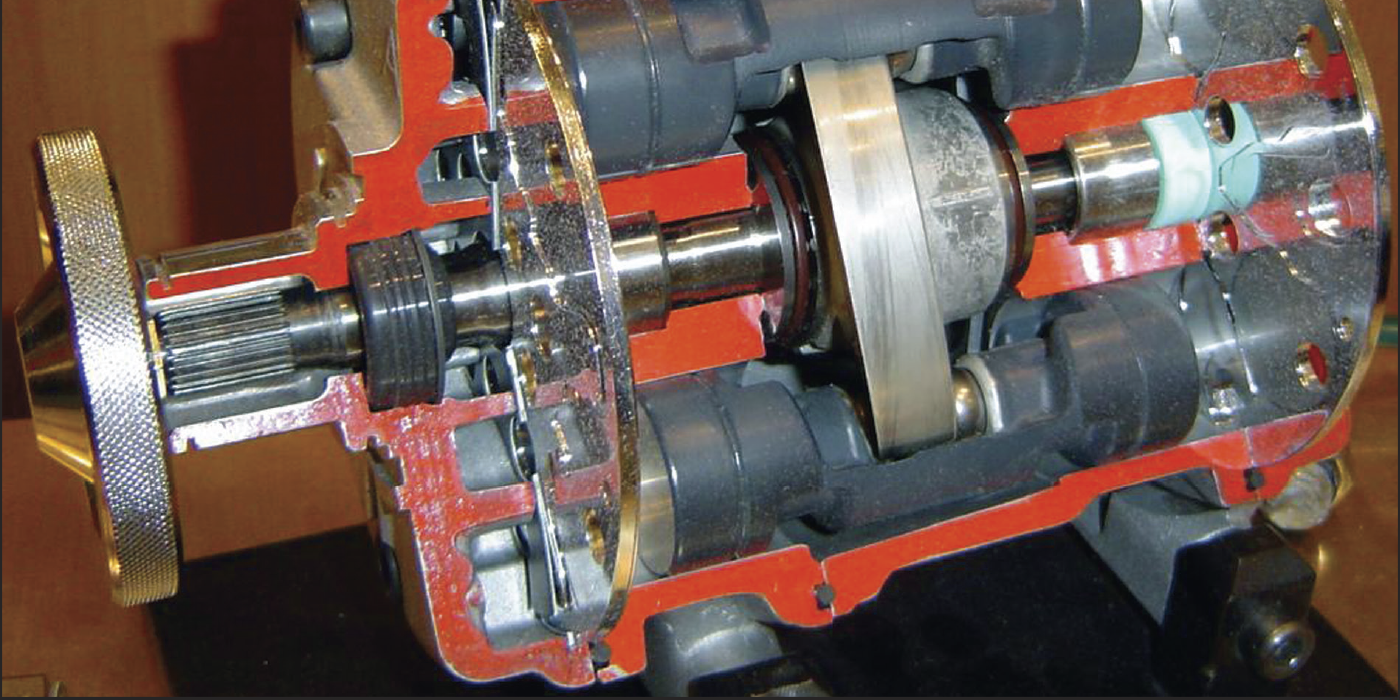

Remember, back in the old days, you had a very large air conditioning compressor. That thing took three to four pounds of refrigerant, and when you pushed the button to turn the air conditioning on, you felt a decrease in performance of the vehicle. That’s because it took a lot of horsepower to push that refrigerant through the air conditioning system. Today, it’s a much smaller deal; with less refrigerant in the system to deal with, the smaller compressor takes a lot less energy.

If you’re running around in a car, crossover or SUV with a 1.4L turbocharged engine, when the air conditioning is turned on, the driver does not feel the effects. Now, global warming is certainly a concern, which is one reason why OEMs began reducing the size of A/C systems. The other concern is mileage.

If a system has an extremely large compressor, it will use more gas. A small compressor allows you to get more gas mileage out of the vehicle with less load on the engine. So that’s why we see a transition to these smaller systems, primarily to get increase the gas mileage.

Equipment Test

When the Mobile Air Climate Systems Association (MACS) conducted its studies in 2007 on J2788, the SAE standard that deals with A/C recovery and recharge equipment, it led to some interesting results.

In its findings, MACS concluded that even with the best machines out there, you were not going to pull all of the refrigerant out of an A/C system during service.

According to MACS’ research, the organization went out and purchased just standard run-of-the-mill air conditioning machines from shops. Some of these had been well maintained, while others were poorly maintained. The MACS team brought the equipment together and began a testing process to determine how well they worked.

Depending upon the ambient temperature, some of the machines could not pull out more than 50 percent of the refrigerant. So, let this sink into your head: If you only pulled half of the remaining refrigerant from the system, you left half behind. If you add another full charge on top of that, you have added full refrigerant on top of left-behind refrigerant.

Here’s a real-world scenario about a car that was blowing cool, not cold. This is not one that had the A/C compressor replaced where it was empty, simply a customer who came in and said, “Hey, it’s not blowing as cold as it was last year, I want it cold this year.”

So, to address the customer’s needs, what your tech does is roll the machine up, and perform a complete cycle — recover it, recycle it, do a vacuum and a recharge to get the customer going. And, that’s the scenario where the chances are highly likely that your tech left refrigerant behind.

Even the best machine that they could find would only pull 70 percent of the refrigerant out at a 50 degree temperature range. Why is a 50 percent temperature used? This is based upon average temperature around the country, and they use that as a standard for testing. We’re going to look at a couple of examples where the car was warmed up and the temperature (ambient temperature) was higher.

So, even in good climate control, even using the best machine that they could find, it was revealed that the equipment operator is still going to leave some refrigerant behind. Now, that surprised me. I was shocked, really, when I looked at the differences between J2810 and J2788.

Here is another real-world example, in which another customer comes into the shop with the complaint that the A/C’s blowing cool, but not cold. Checking under the hood, we find that it’s a 16-ounce system and that it’s at least four to six ounces low, because the performance has reached the point where the temperature is increasing.

This is an expansion valve car, so we predict that when it gets about 30 to 40 percent low on charge, that we’re going to have an issue with the air conditioning performance.

Now, let’s take this example a little bit further. Let’s say you had a machine that is poorly maintained, resulting in you only removing about half of the remaining refrigerant in the system.

So, using the example of a system of 16 ounces, and based on my experience, I estimate that the system is four ounces low. This would mean the refrigerant in the system was around 12 ounces.

With the older, poorly maintained recover machine, only 50 percent of that amount is recovered. That would mean that there’s six ounces remaining in the system.

And, we’ll estimate a charge of 15 ounces refrigerant. When the service is completed, we find that the system is actually five to six ounces overcharged. That’s a lot of refrigerant.