Models

2010-2011 Buick LaCrosse

2011 Buick Regal

2008-2011 Cadillac CTS, CTS Wagon, Coupe (Includes V Series)

2010-2011 Cadillac SRX

2009-2011 Chevrolet HHR

2010 Chevrolet Camaro Built Prior to June 1, 2009 (V8 Engine (All) and V6 Engine (Manual)) or Feb. 17, 2010 (V6 Engine (Automatic))

2010-2011 Chevrolet Equinox

2011 Chevrolet Cruze

2010-2011 GMC Terrain

CONDITION (Cruze, Equinox, HHR, LaCrosse, Regal, SRX, Terrain)

Some customers may comment on a clicking-type noise coming from the front of the vehicle when shifting between reverse and drive or on a hard acceleration.

CORRECTION

CORRECTION

Add a washer between the front wheel drive shaft and the bearing hub assembly using the procedure listed below.

NOTE: Some vehicles may have been built with the washer. If there is a washer already installed, remove and discard it. DO NOT re-use the washer. Replace with NEW only. Any time the wheel drive shaft is separated from the steering knuckle, the washer must be replaced with a NEW washer only.

1. Remove the front wheel bearing and hub assembly. Refer to Front Wheel Bearing and Hub Replacement procedure in service information.

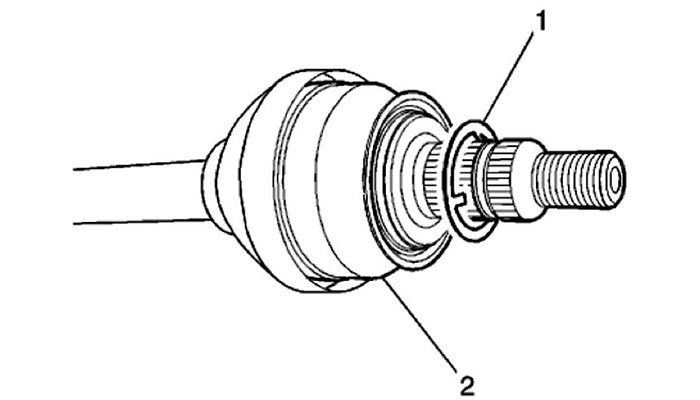

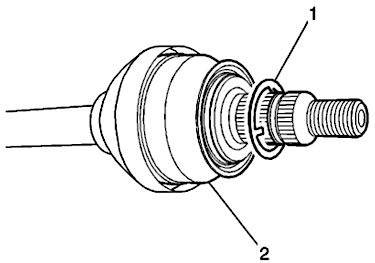

2. Install the washer (1) onto the front wheel drive shaft (2).

NOTE: For Cruze, Equinox and Terrain, DO NOT reuse wheel drive shaft nut. Discard and replace with a NEW nut only.

3. Install the front wheel bearing and hub assembly. Refer to Front Wheel Bearing and Hub Replacement procedure in SI.

4. Repeat Steps 1 through 3 for the opposite side.

CONDITION (CTS, Camaro)

Some customers may comment on a clicking type noise coming from the rear of the vehicle when shifting between reverse and drive or on a hard acceleration.

Correction (CTS, Camaro)

Add a washer between the rear wheel drive shaft and the bearing hub assembly using the procedure listed below.

NOTE: Some vehicles may have been built with the washer. If there is a washer already installed, remove and discard it. DO NOT re-use the washer. Replace with a NEW washer only. Any time the wheel drive shaft is separated from the steering knuckle, the washer must be replaced with a NEW washer only.

1. Remove the rear wheel bearing and hub assembly. Refer to Rear Wheel Bearing and Hub Replacement procedure in service information.

2. Install the washer (1) onto the rear wheel drive shaft (2).

NOTE: DO NOT reuse wheel drive shaft nut. Discard and replace with a NEW nut only.

3. Install the rear wheel bearing and hub assembly. Refer to Rear Wheel Bearing and Hub Replacement procedure in service information.

4. Repeat Steps 1 through 3 for the opposite side.

Courtesy of ALLDATA