Rowing gears with a manual transmission is lots of fun, especially in a lightweight car with way too much horsepower. But when the gears start crunching and the clutch pedal sinks to the floor and you’re stuck at the line or a stoplight, a stick shift suddenly isn’t so much fun anymore.

What’s more, fewer vehicles are coming from the factory with a manual transmission. That can be an issue as new technicians you hire might not have the knowledge base or experience in diagnosing clutch problems to fix a stick-shift vehicle when one comes rolling into the shop.

Clutch problems can be pretty tough to pinpoint, especially without tearing the assembly down to see what’s what. Summit Racing Equipment and Centerforce Clutches put together this primer on troubleshooting a bad clutch. This doesn’t cover every possible issue, but it can help the new guy(s) and act as a mini refresher course for your experienced techs.

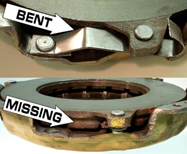

Pressure Plate Drive Straps Bent, Broken, or Missing

Symptoms:

• Difficult shifting (hard clutch engagement/disengagement)

• Clutch noise

Possible Causes:

• Over-aggressive downshifting and missed shifts

• Using clutch as a brake to slow vehicle

Solutions:

• Inspect and resurface flywheel, replace if necessary

• Replace clutch assembly

Clutch Disc Hitting Flywheel or Flywheel Bolts

Symptoms:

• Difficult shifting (hard clutch engagement/disengagement)

• Clutch noise

• Hub spring(s) loose in clutch disc

• Difficulty adjusting clutch pedal freeplay

Possible Causes:

• Clutch disc installed backwards

• Improper flywheel bolts (bolt heads too large)

• Worn flywheel (improper resurfacing or too thin)

Solutions:

• Replace clutch disc

• Inspect pressure plate and replace if worn

• Inspect flywheel crankshaft bolts and replace if worn or improper size

• Inspect flywheel and replace if necessary

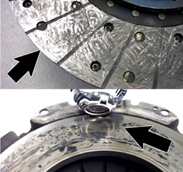

Clutch Disc Friction Material Chipped or Bent

Symptoms:

• Difficult shifting (hard clutch engagement/disengagement)

• Clutch slips—does not hold vehicle power

• Clutch noise

Possible Causes:

• Clutch disc dropped during installation or removal

• Alignment tool not used to install clutch disc

Solutions:

• Replace clutch disc

Glazed Clutch Assembly

Symptoms:

• Clutch slips—does not hold vehicle power

• Premature clutch wear

Possible Causes:

• Improper break-in procedure

• Excessive clutch preload (improper adjustment)

• Excessive clutch slip due to driving style

• Oil leak from engine or transmission

Solutions:

• Repair oil leak, clean bellhousing and clutch release components

• Inspect and resurface flywheel, replace if necessary

• Adjust clutch pedal freeplay

• Replace clutch assembly and follow proper break-in procedure

Throwout Bearing and/or Clutch Fork Installed Improperly

Symptoms:

• Hard and/or pulsating clutch pedal

• Throwout bearing noise

• Difficult shifting (hard clutch engagement/disengagement)

Possible Causes:

• Fork and/or throwout bearing installed incorrectly

• Excessive clutch preload (improper adjustment)

• Clutch release linkage worn or damaged

Solutions:

• Inspect throwout bearing for wear and replace if necessary

• Inspect transmission input shaft collar for wear and replace if necessary

• Inspect pressure plate diaphragm fingers and replace pressure plate if necessary

• Adjust clutch pedal freeplay

• Inspect clutch release linkage and replace if necessary

Worn Diaphragm Fingers on Pressure Plate

Symptoms:

• Difficult shifting (hard clutch engagement/disengagement)

• Difficulty adjusting clutch pedal freeplay

• Clutch slips—does not hold vehicle power

• Premature clutch wear

Possible Causes:

• Improperly installed throwout bearing

• Excessive clutch preload (improper adjustment)

Solutions:

• Replace throwout bearing

• Inspect transmission guide tube and bearing collar for wear, repair or replace if necessary

• Adjust clutch pedal freeplay

• Inspect and resurface flywheel, replace if necessary

Pressure Plate Overheated–Severe Hot Spots

Symptoms:

• Clutch slips—does not hold vehicle power

• Clutch shudders (chatters)

• Premature clutch wear

Possible Causes:

• Improper break-in procedure

• Excessive clutch preload (improper adjustment)

• Excessive slippage due to aggressive driving style

Solutions:

• Inspect and resurface flywheel, replace if necessary

• Adjust clutch pedal freeplay

• Replace clutch assembly and follow proper break-in procedure