By Larry Carley

Technical Editor

Question: My engine burned a piston. What does that mean and why did it happen?

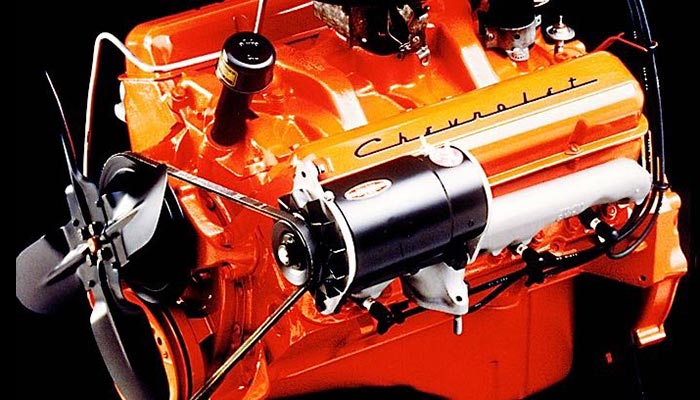

Answer: It means the piston failed due to excessive heat in the combustion chamber. A burned piston will typically have a melted appearance, or a hole burned completely through the top of the piston. Aluminum can only withstand so much heat, and when it gets too hot, it melts. The underlying cause is usually detonation and/or pre-ignition.

Detonation occurs when the temperature and pressure inside a cylinder exceed the fuel’s octane rating. Instead of igniting when the spark plug fires, the air/fuel ignites spontaneously much like a diesel engine. This creates multiple flame fronts within the combustion chamber that collide and hammer the top of the piston, producing a metallic knocking noise called “spark knock.”

Common causes of detonation include a buildup of carbon deposits in the combustion chamber and on the top of the piston that increase compression, no EGR (exhaust gas recirculation), overadvanced ignition timing, a bad knock sensor, a lean fuel mixture, low quality gasoline that does not meet minimum octane requirements, or any cooling problems that causes the engine to run hotter than normal (coolant leak, low coolant level, bad water pump, stuck thermostat, restricted radiator, defective cooling fan, even exhaust restrictions that back up heat into the engine.

Pre-ignition occurs if a hot spot develops in the combustion chamber that ignites the air/fuel mixture before the spark plug fires. The hot spot may be the spark plug itself, an overheated exhaust valve, carbon deposits in the combustion chamber, or a sharp edge in the combustion chamber.

Common causes of pre-ignition include the wrong heat range spark plugs (too hot for the application), carbon deposits in the combustion chamber and on the tops of the pistons, a lean fuel mixture, detonation or anything that makes the engine run hotter than normal.

On engines that are turbocharged or supercharged, too much boost pressure and/or not enough fuel can burn a piston very quickly. Check the operation of the wastegate and boost control system. If the turbo system has been tweaked to deliver higher than stock boost pressure for more power, the turbo may be pushing more air into the engine than the stock injectors can handle, causing the fuel mixture to lean out and burn the piston.

An often overlooked cause of piston burning is a weak or dirty fuel injector. If an injector is not spraying enough fuel into the combustion chamber, the air/fuel mixture in that cylinder may become too lean increasing the risk of detonation, pre-ignition and piston damage.

Diagnosis requires using a scan tool to check for lean codes and to look at fuel trim values. If a P0171 or P0174 code is found, or the long term fuel trim readings are 10 or higher (indicating a lean mixture), the engine may have one or more weak or dirty injectors.

The only way to know for sure is to remove the injectors, clean them on a fuel injector cleaning machine, then flow test all the injectors and compare the results. Any injector that does not flow within 5 to 8 percent of the rest should be replaced.

Question: What is a ‘scuffed’ piston?

Answer: A scuffed piston is one that has been damaged by rubbing against the cylinder wall. The metal-to-metal contact smears the metal on the skirt on the piston and damages the piston.

Scuffed pistons can be caused by too much heat in the combustion chamber, engine overheating or inadequate lubrication. The piston-to-cylinder clearances in most late model engines is much less than it used to be to reduce piston rock and noise. Consequently, if the piston or cylinder gets too hot, the clearance goes away and you get metal-to-metal contact.

In instances where piston scuffing occurred due to a loss of lubrication, the underlying cause may be a low oil level in the crankcase (due to a lack of maintenance or an oil leak), low oil pressure (a worn oil pump), poor oil quality, or oil breakdown (not changing the oil often enough).

When diagnosing a scuffed piston, note where the piston is scuffed. If the cause is overheating, the scuffing will mostly be on the upper ring lands and on the sides near the wrist pins.

There may also be oil carbon and lacquer burned onto the underside of the piston indicating it got too hot. Scuff marks on the lower skirt area often indicates a lack of lubrication (check the oil pump and pickup screen). Scuff marks on the edges or corners of the thrust sides of the piston may be the result of bore distortion. Scuffing on both thrust sides would indicate binding in the wrist pin.

Some original equipment pistons and many aftermarket performance pistons now have special anti-scuff skirt coatings to reduce the risk of scuffing.