As part of its commitment to providing low-cost vehicle stop leak solutions, Bar’s Leaks introducesConcentrated Rear Main Seal Repair. The new concentrated formula provides the same unique blend of polymers, lubricity agents, anti-oxidants and conditioners as the original Rear Main Seal Repair in a much smaller bottle: 16.9 oz. vs. 32 oz.

“Bar’s Leaks has offered affordable stop leak solutions since 1947,” explains Clay Parks, vice president of development. “As the cost of some of the non-essential ingredients in our product has increased, we looked at the best ways to keep our price as low as possible for our customers. Reducing the base oil while maintaining the same level of key additives allows us to offer a Concentrated Rear Main Seal Repair that will stop all oil leaks very affordably.”

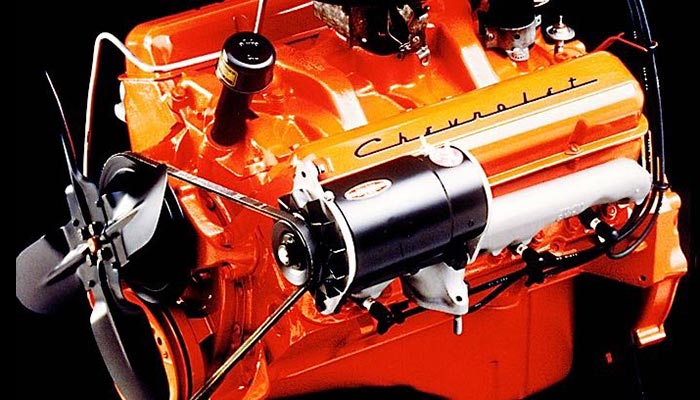

Persistent engine oil leaks usually can be traced to the vehicle’s rear main seal. Replacing this seal is a labor-intensive job that can cost upwards of $500, but ignoring the leaks can result in even more expensive damage to electrical components, rubber hoses, rubber engine mounts and other parts. Bar’s Leaks Concentrated Rear Main Seal Repair (p/n 1040) is specially formulated to stop leaks at the rear main seal, and it also works better than a conventional stop leak on all other oil leaks, including those at the timing cover seal, O-rings and other seals and gaskets.

The rear main seal is located between the engine and transmission. Leaks here are usually caused by a combination of normal wear in the crankshaft and seal, and by the drying, hardening, and shrinking of the seal over time. Bar’s Leaks Concentrated Rear Main Seal Repair restores seal size, flexibility and elasticity. Chemical polymers in the product also fill in gaps and grooves in the crankshaft caused by normal engine wear, and build a protective film around the seal to prevent leaks.

Bar’s Leaks Concentrated Rear Main Seal Repair works with all gasoline and diesel engines that use conventional, high-mileage or synthetic motor oil. One bottle treats four to six quarts of oil. Larger systems use one bottle for every five quarts of oil capacity.

Like all Bar’s Leaks products, Bar’s Leaks Concentrated Rear Main Seal Repair is made in the U.S.A. The label includes directions in both English and Spanish.

For more information about Bar’s Leaks Concentrated Rear Main Seal Repair, call (800) 345-6572, email [email protected] or visit the website at www.barsleaks.com. You can also follow Bar’s Leaks on Twitter at twitter.com/barsproducts, on Facebook at www.facebook.com/barsleaks, on YouTube at www.youtube.com/barsproducts and through the blog at www.barsproducts.com/blog.