Common rail injection has been in existence for a long time but has become more popular in diesel engines over the past decade. In order to have a cleaner running engine, you have to make it more efficient.

One thing that has been discovered with diesel fuel injection is the higher the pressure at which it is injected creates more efficiency. The purpose of common rail injection is to deliver high-pressure fuel to the injector. Fuel in a common rail system will be injected into the combustion chamber through the injector nozzle at pressures as high as 28,000 psi. This is far from the mechanical systems of the past that would inject fuel into the combustion chamber at 2,000 to 3,000 psi.

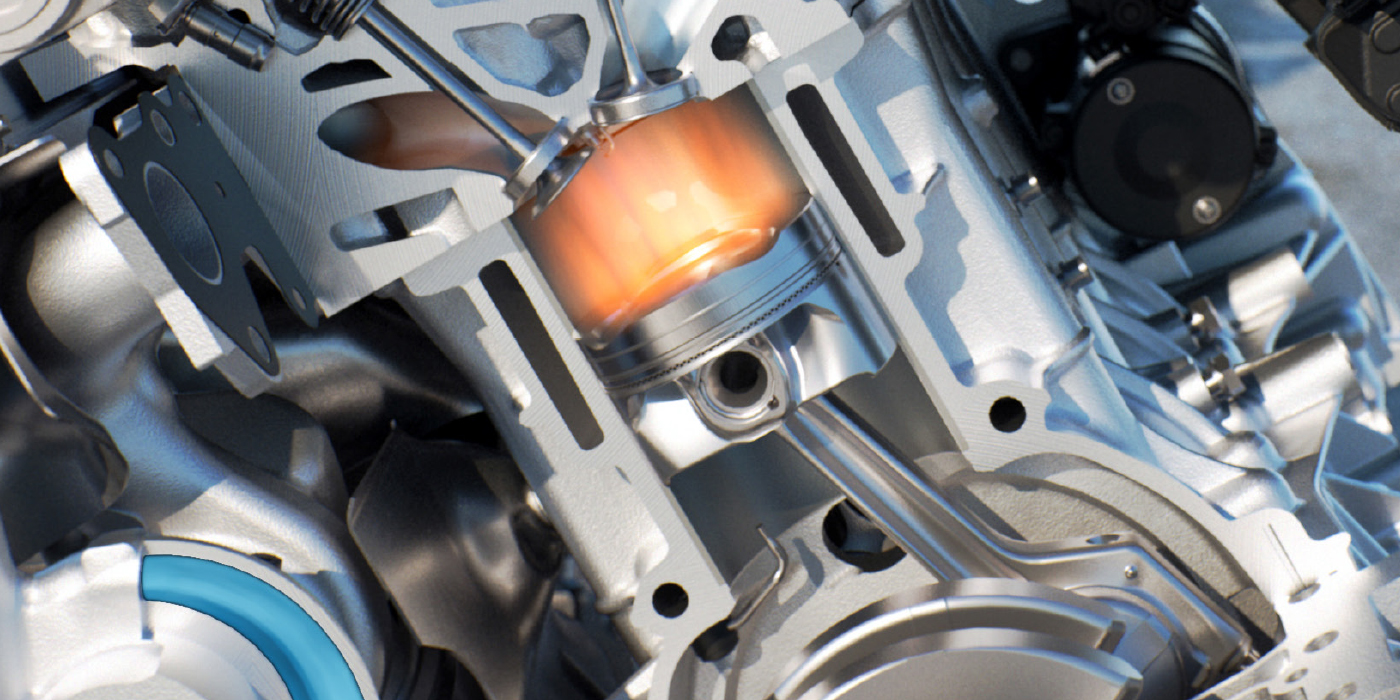

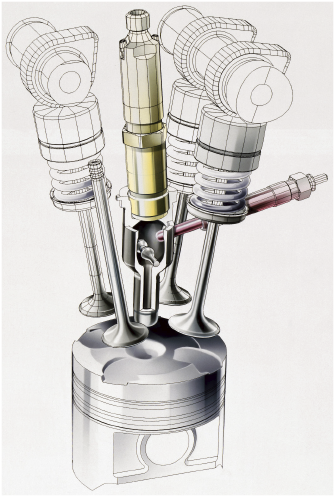

When diesel fuel is injected at high pressure, you can only imagine the difference in the fuel atomization. Fuel atomization, along with port swirl, is the biggest contributing factor to the efficiency of today’s diesel engines. The increased atomization of fuel from the common rail injection also created design changes to the piston and combustion chambers along with the design of the intake ports and valve train.

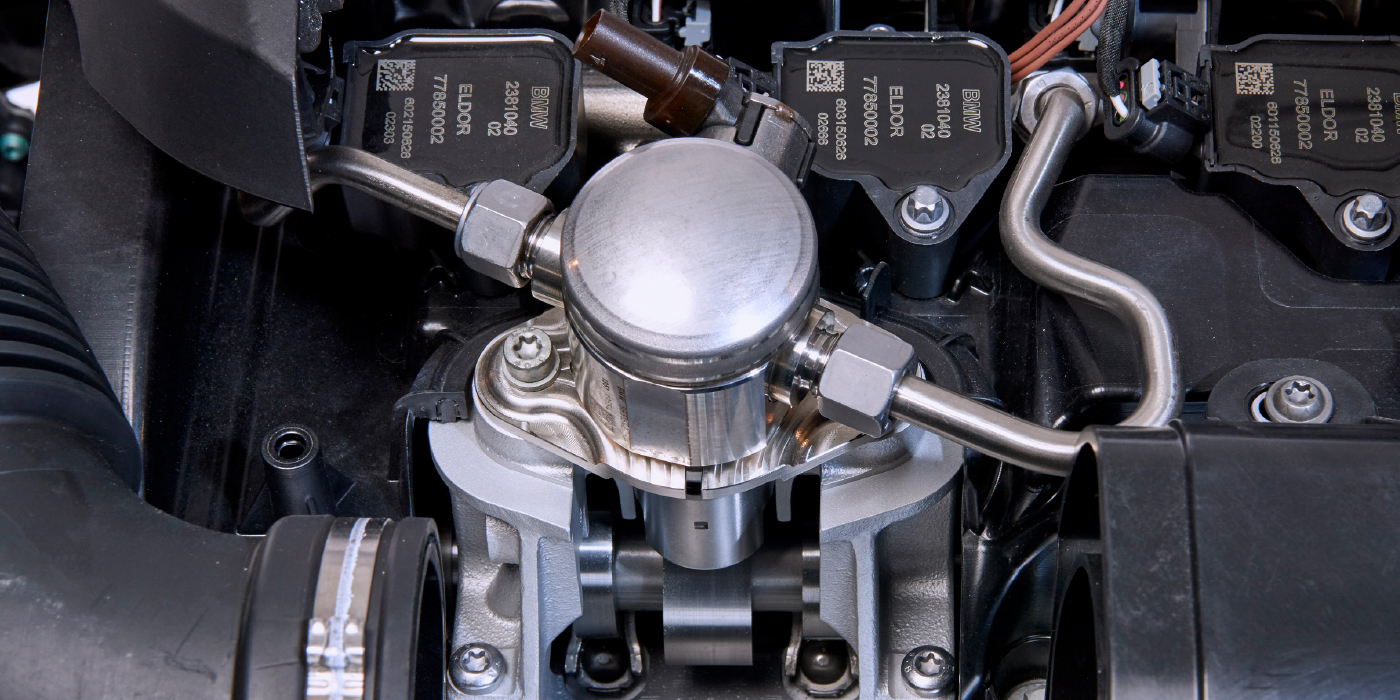

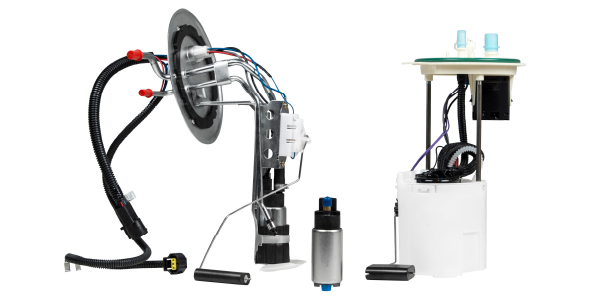

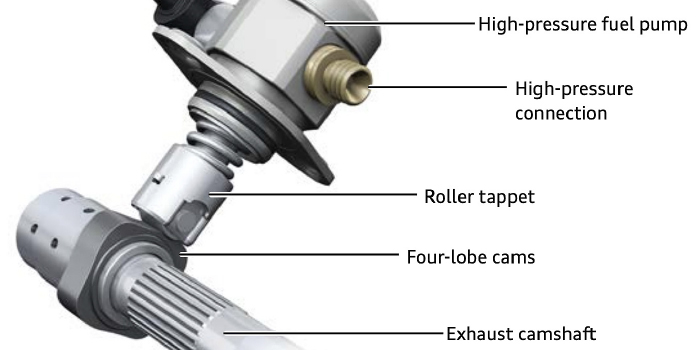

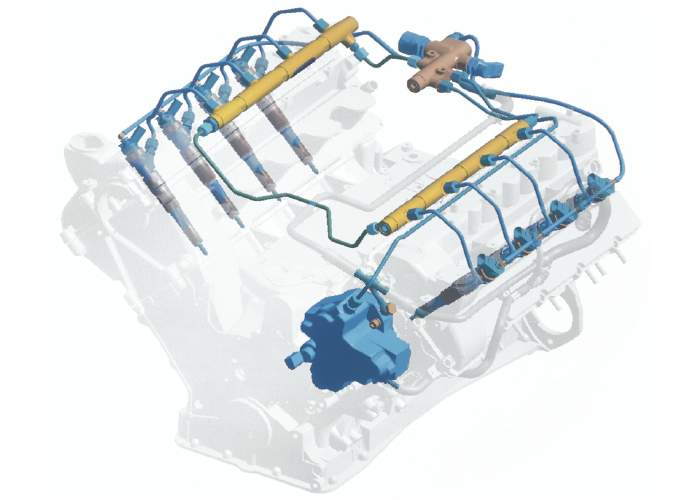

In order to inject diesel fuel at high pressures, you need a very unique pump known as a high-pressure fuel pump. The pump is usually engine-mounted and driven by the engine gear train. A regulator controls the amount of pressure that the pump makes. The regulator, also known as the fuel-metering valve, regulates the amount of fuel that the high-pressure fuel pump will intake.

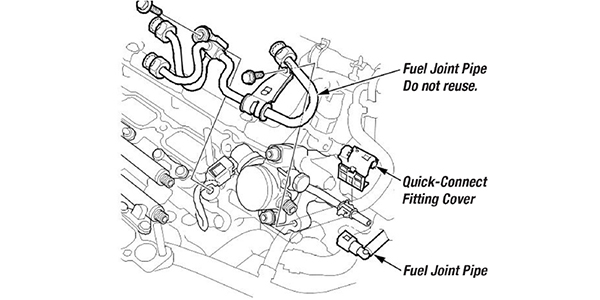

Even though the engine drives the high-pressure pump, the pump will produce the necessary high pressures regardless of the engine speed. After the pump has been pressurized, the fuel is stored in the fuel rails. The fuel rails are accumulators for the high-pressure fuel to be delivered to the injectors through lines that branch off of them. The fuel rails also dampen vibrations from the high-pressure fuel pump and injection cycles from the injectors.

Inside the fuel rails is a fuel rail pressure sensor that reads the pressure in the fuel rail for the Powertrain Control Module (PCM). The PCM uses the input from the fuel rail pressure sensor to determine how much to open the fuel regulator. If more pressure is needed, the PCM will command the regulator to open for more fuel to be taken in by the high-pressure pump.

A fuel rail pressure control valve also controls high-pressure fuel in the fuel rails. The pressure control valve is usually placed in the end of the fuel rail where it will be opened or closed by the PCM for precise pressure control inside the fuel rails. This helps to keep the optimum fuel pressure in the fuel rails to be delivered to the injectors for various demands placed on the engine.

Just in case the fuel pressure was to spike abnormally, the fuel rails have a fuel rail pressure limiter inside of them as well. If fuel pressure were to get out of hand for some strange reason, the limiter would open, allowing the excess pressure to return to the fuel tank.

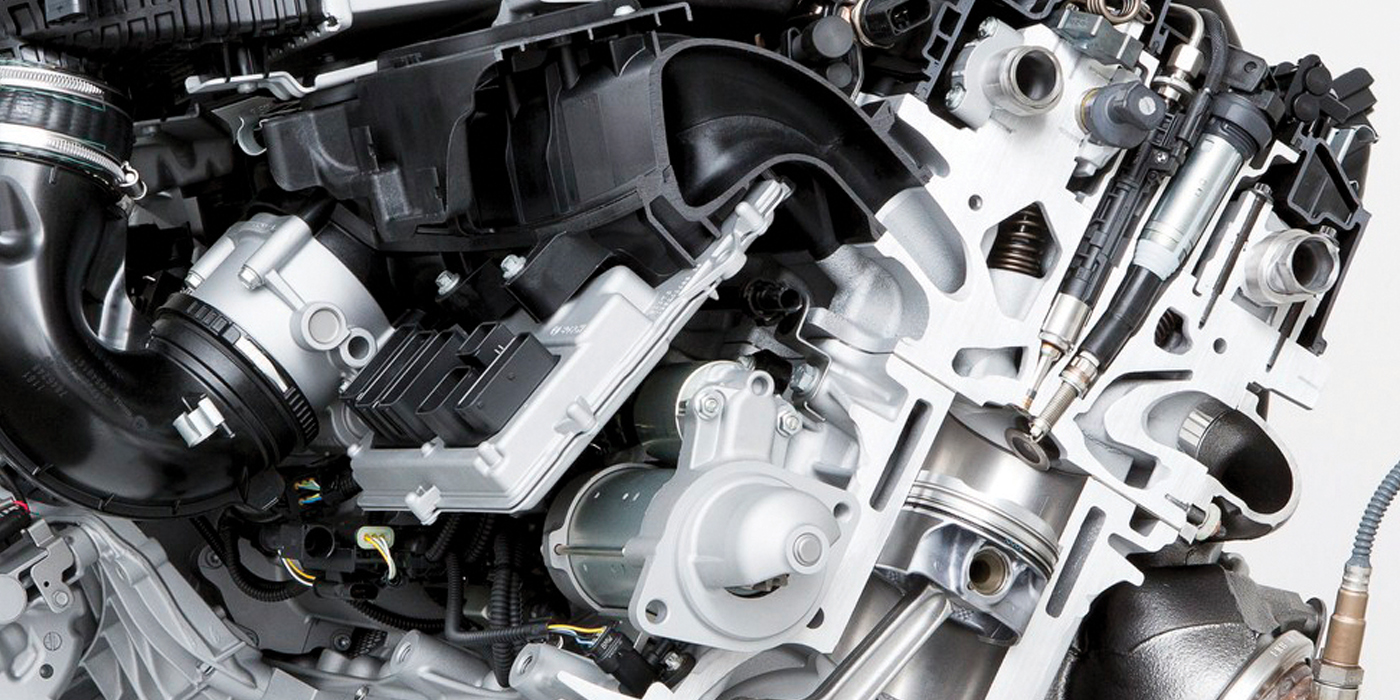

As high-pressure fuel travels through the rails and lines, it arrives at the injector, which is controlled by the PCM. When the PCM commands the injector to open, fuel enters the injector and is sent through some intricate passages in the injector that leads to the injector’s tip.

The tip of the injector has microscopic holes through which the fuel will be delivered as a very fine mist. The droplet size of the fuel as it is sent through the tip is about 7 times smaller than a human hair. Injectors can be actuated by a solenoid type of driver or a Piezo electric device.

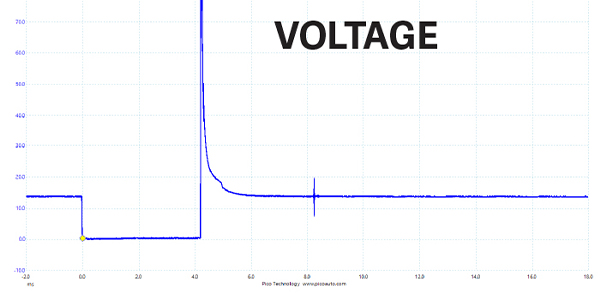

Solenoid-actuated injectors have been around for some time, but have been replaced with Piezo actuation. Piezo is a type of crystal that is wafer-thin and generally stacked on top of each other. These stacks of Piezo crystals, when energized by the PCM, will expand and open the injector’s valve, and its actuation is 4 times faster than a solenoid.

The PCM uses inputs from sensors on the engine to control actuators, which control fuel delivery. Fuel delivery is based upon demands on the engine, such as the amount of boost, the throttle position, engine temperature, etc. With the use of common rail, there can be multiple injections per combustion cycle. This can also be beneficial during cold weather start-ups.

The use of common rail has brought about many advantages to the diesel engine. These advantages are higher injection pressures for increased atomization of fuel, multiple injections per combustion cycle, and more reliable pressure regardless of engine speed.