Delphi Product & Service Solutions (DPSS) announces five new accessories for its diagnostics scan tools.

Delphi Product & Service Solutions (DPSS) announces five new accessories for its diagnostics scan tools.

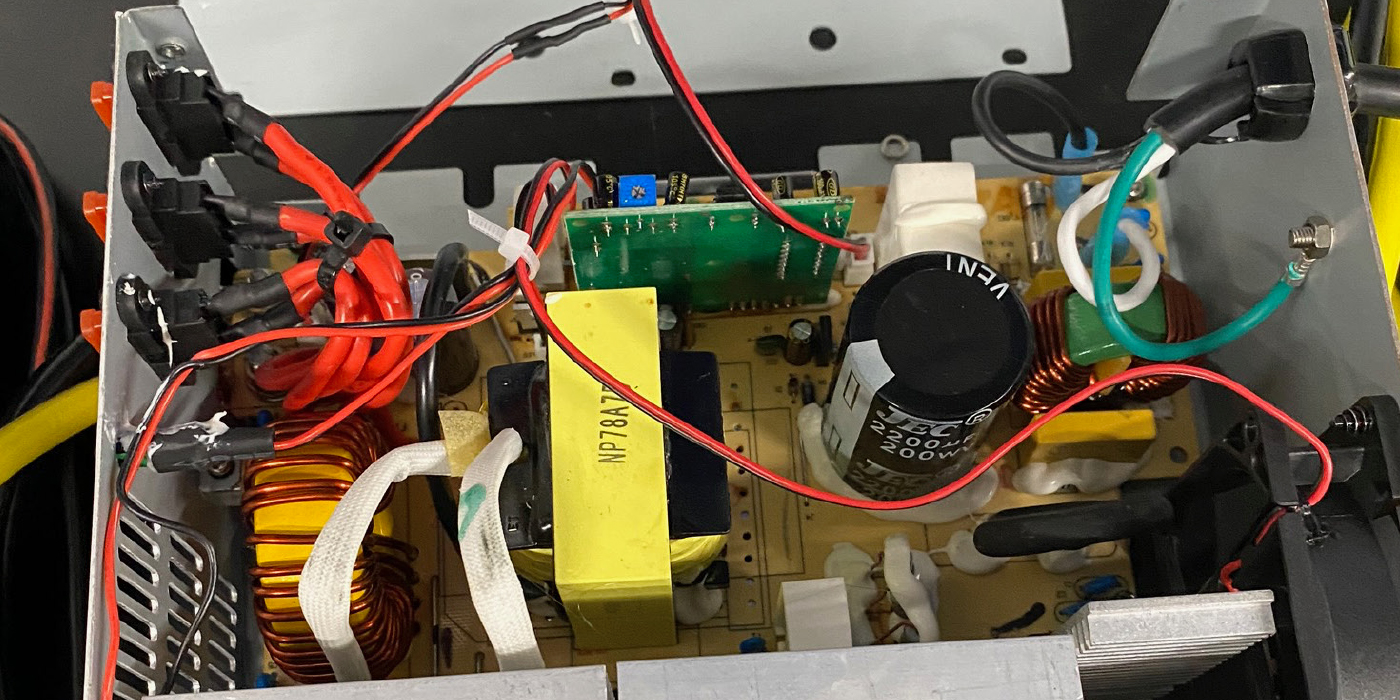

Delphi’s Diagnostic Scan Tool and Flash Programmer are complete diagnostic solutions for vehicle service and repair. Operating on a PC-based platform, technicians connect the tool to the OBD II connector under the instrument panel to determine trouble codes and are guided to the suspect area. Technicians can use the tool, which has access to the latest OE data and software, to get current service repair information (with subscriptions after the first six months) and dedicated tech support.

Three Reasons To Choose Delphi’s Diagnostic Scan Tool:

1. Integrates Into Any Shop’s Existing Platform

Each of the three technician-focused kits includes cables, adaptors, external VCI power supply diagnostic software, flash reprogramming, rugged carrying case and one-year warranty. No keys or adapters are required. The simple vehicle connection uses a standard OBD II J1962 connector. Delphi also offers a compact, WiFi-ready touch-screen tablet PC (with SV34000 only).

2. Broad Coverage

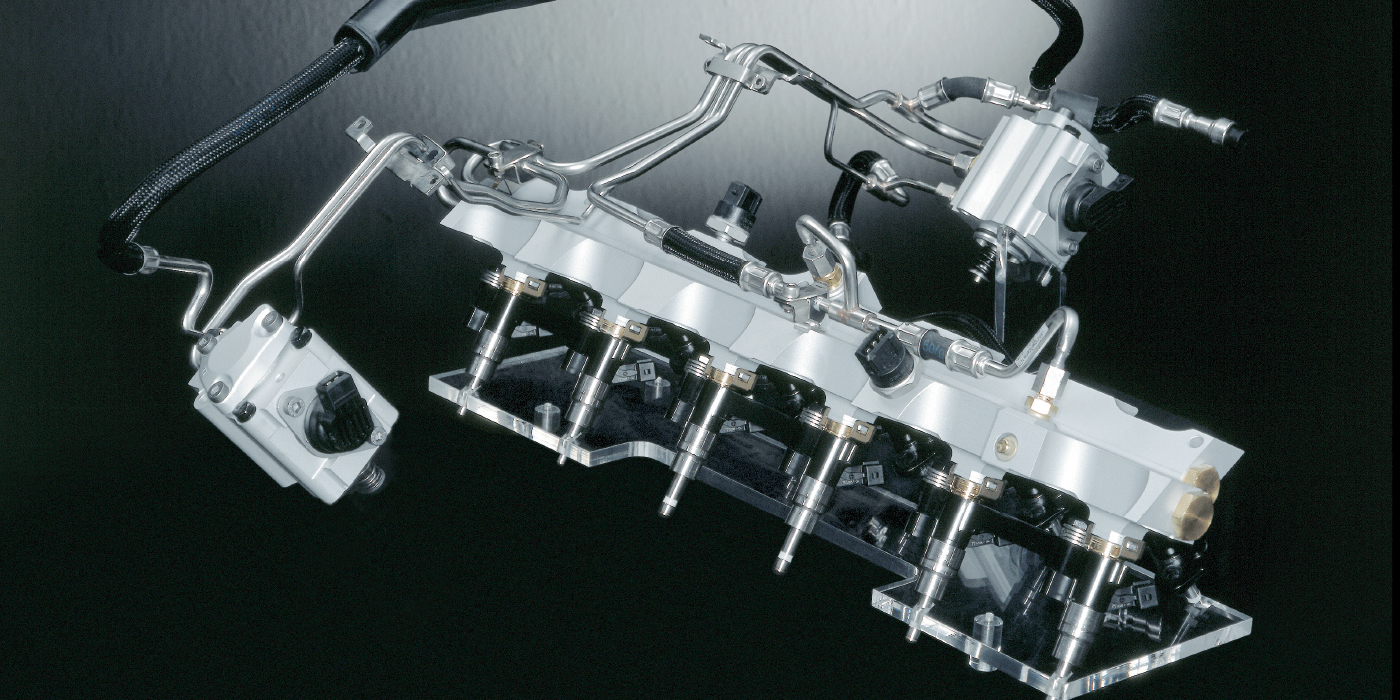

Coverage for all domestic and leading Asian vehicles starts with the 1996 model year, with European applications available in early 2014. The tool covers hundreds of modules and thousands of active commands for powertrain, body and chassis systems.

3. Updated Easily

The tool is designed for expanded capabilities and can be updated through Internet downloads. Through yearly updates, technicians can stay ahead of diagnostic systems from the latest generation of vehicles on the market.

Visit go.delphi.com for specific part information. Inventory is available now.