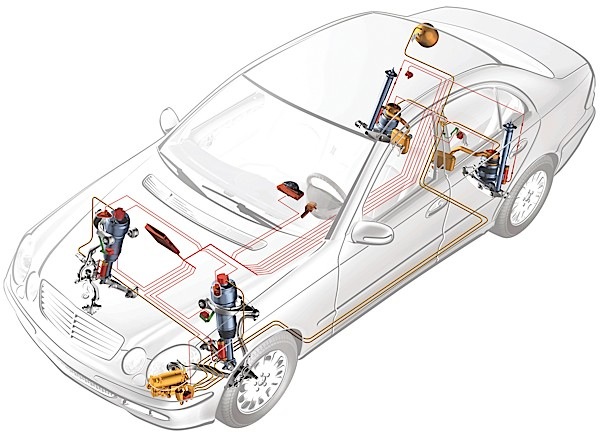

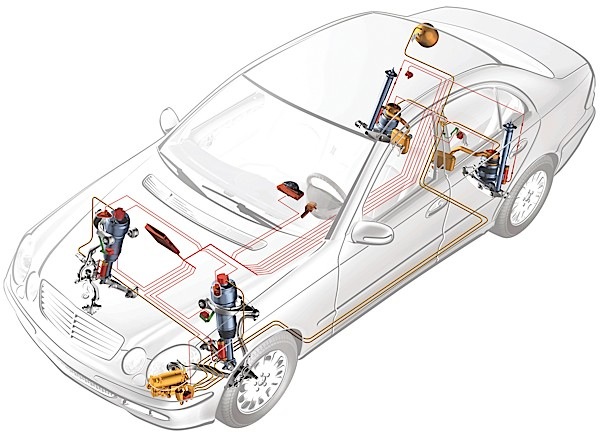

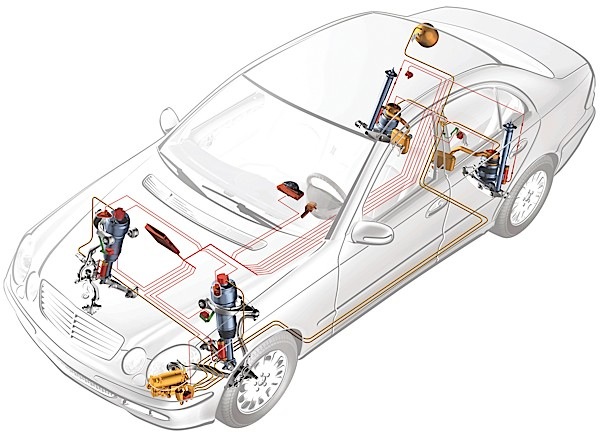

On most modern vehicles, the compressor and air ride control unit are very intelligent components. Most communicate with the Body Control Module (BCM) on a high-speed serial data bus. These systems have malfunction indicator lights on the dash and require the use of a scan tool to diagnose the system.

Servicing modern air ride systems requires the right service information to interpret the “C” or chassis codes the air ride system can generate. A failure code and an illuminated dash light could be just a failure of the air ride module to communicate with the BCM. This could be due to electrical problems and not a leak in the air system or a compressor failure.

With an enhanced or factory scan tool, it is possible to perform bi-direction tests on the compressor and valves during inspection. This can save you hours of diagnostic time waiting for a compressor to turn on and drain the battery or testing for an intermittent condition. Throwing parts at these vehicles without performing a proper diagnosis can result in an unhappy customer and lost productivity.

The air ride module does more than control the ride height. The software controls the temperature of the compressor so it does not damage itself trying to inflate a leaking air bag. It can also change the characteristics of the air bag in response to how fast the vehicle is going and if it is in sport or towing mode. But most of all, it helps to filter out erroneous ride height readings so the best possible ride is achieved.

Compressor Killers

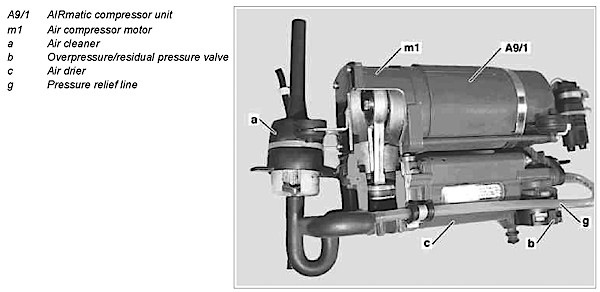

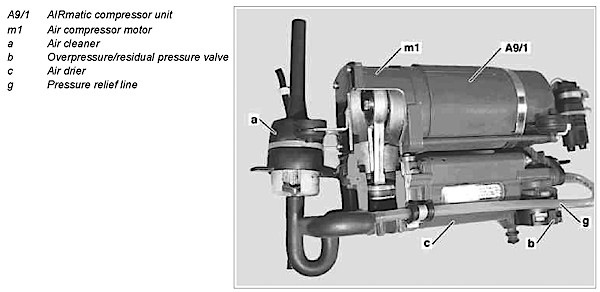

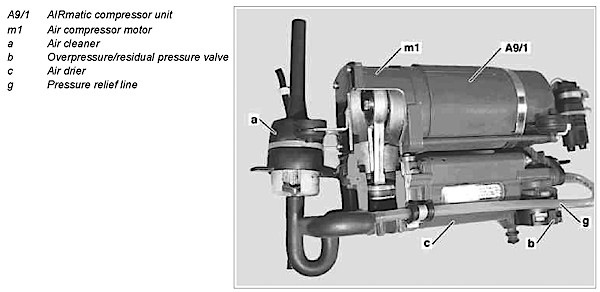

Most passenger and light-truck compressors are diaphragm types that supply an oil-free air supply to the springs. A piston-type compressor can be found on applications that require a higher volume of air.

Running the compressor for extended periods can over heat the compressor and damage the diaphragm or piston. It is very important to ensure that the source of air for the compressor is clean and as dry as possible.

In the air is moisture that can damage not only the compressor, but the valves. When air is compressed, the water vapor contained in the air is condensed into a liquid. If there is no means of removing the water from the system, it will find its way to all parts of the system causing corrosion damage or freezing.

Most systems have a dryer that is connected to the compressor outlet to absorb the water entering the system. The dryer contains a moisture-absorbing desiccant such as silica gel. The desiccant can hold a given amount of water and once the desiccant is saturated with water, it will allow water to pass into the system.

The dryers that are installed on most systems do not have an indicator that will show when it is saturated and no longer able to absorb water. An additional dryer with a moisture indicator can be added to the original equipment dryer. It can be installed in the supply line and placed in a position where a periodic check can be made.

Some systems have filters on the air intake for the pump. The filter removes airborne particles and acts as a noise muffler for the compressor. Some systems even send purged air back through the filter. This filter should be replaced with the compressor, and often this filter is attached to the compressor’s casing.

Another killer of air-ride components is the compressor. As the compressor over heats and wears, it can send debris and oil to the rest of the system. This oil and debris can degrade the air bellows even after the compressor is replaced. This is why it is critical to flush the lines if a compressor has failed.

Some systems have air reserve tanks or accumulators located in the most inconvenient locations, like below the C-pillar or next to the frame rail. If the system experiences a catastrophic failure of the compressor or air bladder, replacement or flushing of the reserve might be required.

The health of the entire system depends on the quality of the air supply. It is rare for just one component of an air suspension to fail.

Mechanical and Solenoid Valves

There are various combinations of both mechanical and solenoid valves.

The function of the mechanical or solenoid valve is to exhaust air from the spring(s). Each spring can have a valve. For the Lincoln air suspension system, there are five solenoid valves — one for each air spring or strut and one to exhaust air from the system.

Most valves are used for a pair of load-assist springs. The compressor unit contains a one-way check valve to isolate it from the springs or a reservoir. The Lincoln compressor has a combination one-way check valve and exhaust solenoid valve to inflate or exhaust the springs individually. Whether the valve is mechanical or solenoid, it needs dry air to operate properly.

Plastic line is used to transport air in the system in sizes 1/4”, 3/8” and 1/2”. Most fittings are push-on O-ring type ranging in size from 1/8” to 3/8” Male NPT.

Air struts for some import vehicles can have even more complex valves, air chambers and accumulators on the strut body to keep the suspension taut under certain conditions. These types of struts will have both an air and electrical connection to control the valves on the strut and the hydraulic valves of the dampener.

Dynamic Vehicle Trim

The Lincoln Continental Mark VIII is equipped with ride height sensors at each front wheel and one for the live rear axle at the driver’s side control arm. The sensors provide input to the controller for ride height. The suspension controller is programmed for two different ride heights.

Parked, the vehicle will maintain this height by compensating for passengers and luggage. When the vehicle is put into gear, the controller will raise the suspension ride height 0.75 inch (20 mm). When vehicle speed exceeds 63 mph (105 kph), ride height is lowered by 0.75 inch (20 mm). When vehicle speed decreases to 45 mph (72 kph), the vehicle ride height is increased. The differential between 45 and 63 mph provides a dead band where the system will not adjust ride height. This prevents the system from cycling with small changes in vehicle speed. With the ignition off and doors closed, the vehicle returns to parked height.

The rear air struts on GM vehicles are used to assist the conventional coil springs. Cadillac vehicles with Road Sensing Suspension (RSS) have an electrically operated hydraulic valve located at the base of the air shock. There are sensors located at each wheel that supply input to the ride controller that operates the valves in the air shock and front struts. The suspension height sensor is located on the driver-side control arm and the compressor is located in the rear suspension cradle.

Alternatives

There are suppliers that can provide economical replacements for both springs and struts. These alternatives replace the air ride components with springs and conventional ride control units. On some vehicles that still have 100,000 of miles of useable service left, these kits can offer an economical option for the driver. Also, some remanufacturers are willing to pay for the worn air ride shock or strut cores that come off the vehicle. In some cases, the core could be worth $300!