Oil And Direct Fuel Injection

The oil in the crankcase of a direct fuel injected engine can make a huge difference in the health of the engine. The right oil can reduce carbon deposits on the intake valves and keep the engine healthy.

Hyundai Fuel System And Emissions Diagnostics

Bob Dowie recently had a 2002 Elantra GLS in the shop. This vehicle is a good example of some common fuel trim and emissions problems you’ll see.

Fuel Pump Diagnostics: Using Scan Tools

The most common diagnostic procedures for fuel pumps in the past were analog and hands on. Most fuel pump-related problems could be solved with a pressure gauge and voltmeter. Today, the scan tool is the most important tool when diagnosing a fuel supply problem.

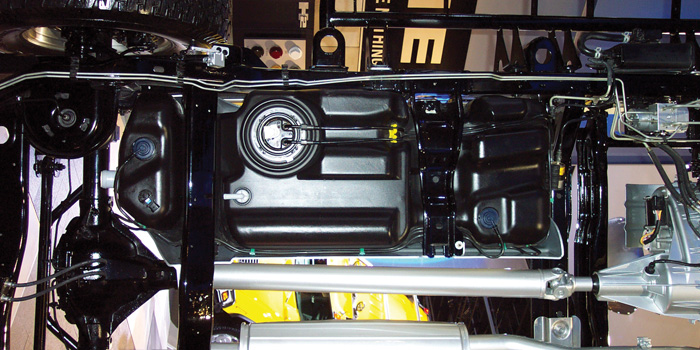

Subaru Pulse-Width Modulated Fuel Pumps

I think it might have been a 2003 Subaru WRX, but it was parked in front of my local Subaru specialist’s shop after going on its fourth fuel pump replacement from other shops in less than six months. Both the Subaru specialist and I agreed that fuel pump failures on Subarus were relatively rare, so the previous repair shops had obviously overlooked some very important details.

Direct Injection And Carbon Deposits

In 1985, Saab began using the new Bosch LH fuel injection system, and Volvo and other carmakers followed suit. The system worked such that incoming air passed through an airflow meter that sent a signal to the engine ECU telling it how much air was going into the engine. The coolant temp sensor then told the ECU how cold or warm the engine was, and it opened and closed the injectors when needed.

Carter Fuel Systems Introduces 12 New Part Numbers

Carter Fuel Systems, a U.S.-based manufacturer of complete fuel system solutions, has announced the introduction of 12 new part numbers covering a series of model year applications ranging from 2005-’15. Extending coverage to reach 6.2 million additional passenger vehicles, the new part numbers include seven high-pressure gasoline direct injection (GDI) mechanical fuel pumps and five

Carter Fuel Systems Introduces 13 New Part Numbers

The 13 new part numbers cover a series of model year applications ranging from 2001-’14, extending coverage to reach an additional 2.7 million passenger vehicles.

Automotive Fuel Pumps Continue To Evolve

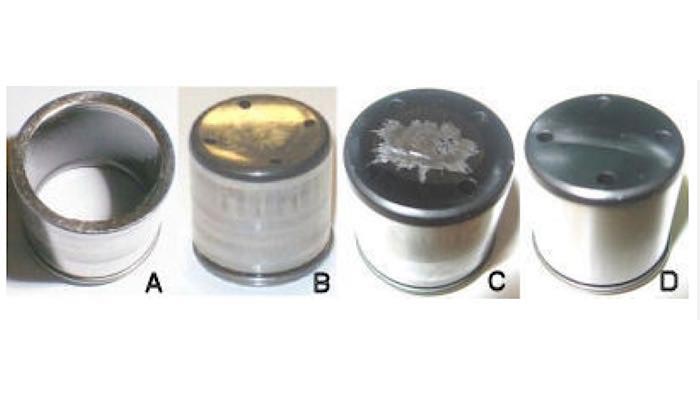

On most applications, the pump runs at a constant speed (typically 3,000 to 7,000 RPM depending on the design). However, on many newer vehicles, pump speed is controlled by the PCM and will vary depending on engine load and speed. The most common type of electric fuel pump today is the turbine style pump. An impeller ring with many small blades is attached to the electric motor inside the pump.

Carter Fuel Systems Introduces 45 New Part Numbers

Carter Fuel Systems, a U.S.-based manufacturer of complete fuel system solutions, has announced the introduction of 45 new part numbers, including 39 fuel pump module assemblies, three electric fuel pumps and three gasoline direct injection (GDI) mechanical fuel pumps. “2016 has already been a tremendous year of growth for Carter Fuel Systems,” said Mellissa Krause,

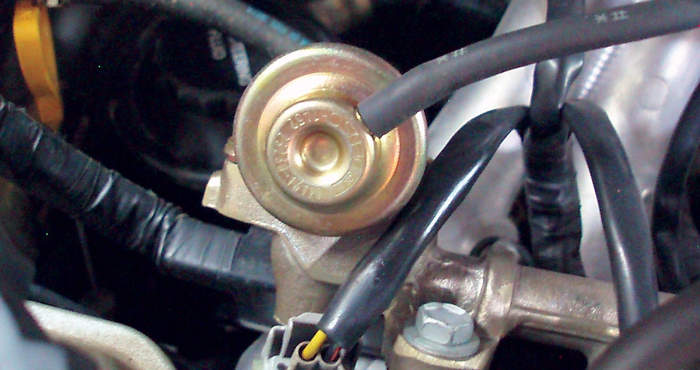

Diagnostic Solutions: Fuel System Pressure & Volume Checks

For maximum efficiency, modern import fuel injection systems require that fuel be delivered at a specified volume and pressure. Because the fuel injector’s job is to mix fuel with the intake air charge, it must produce a finely misted, conical spray pattern through the fuel injector nozzle. Lower-than-specified fuel pressures not only fail to provide enough fuel for combustion at larger throttle openings, but may also introduce an uneven air/fuel charge distribution into the combustion chamber itself, which usually results in hard starting, hesitation and reduced power output.