The oil in the crankcase of a direct fuel injected engine can make a huge difference in the health of the engine. The right oil can reduce carbon deposits on the intake valves and keep the engine healthy. Many manufacturers have recommended specific oil grades that meet proprietary requirements in recent years. These are not to be ignored if you are changing the oil on a direct injection engine.

General Motors was one of the first to do this when they updated their Dexos oil to Dexos 2. Volkswagen has also rolled out oil specifications for certain direct injection, turbocharged engines. But, the biggest change will come when GF-6 oils hit parts store shelves next year.

Oil Volatility

Some consumers and technicians think if they change their oil every 3,000 to 5,000 miles with conventional oil on a direct injection engine that they are preventing problems and saving on the expense of having to purchase synthetic oil. The reality is that they could be making the problem worse.

Most conventional oils have high volatility numbers. If an oil has a high volatility number, it vaporizes more quickly when exposed to heat. This means that the oil can become thicker over time and won’t lubricate as well. It also means that there is a greater volume of oil vapor the PCV system has to process. These vapors can be loaded with hydrocarbons and stick to the intake valves, causing a carbon deposit problem. Synthetic oils have much lower oil volatility. This reduces the amount of oil vapor and the possibility of carbon deposits forming on the intake valves.

Volatility & Low-Speed Pre-Ignition

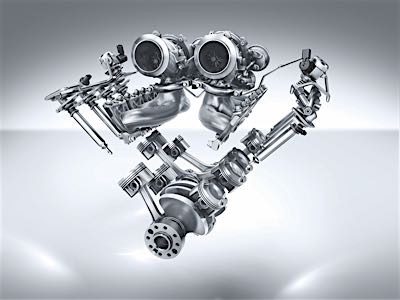

The other issue the volatility of engine oil presents that is being investigated by engineers and chemists is Low-Speed Pre-Ignition (LSPI) on direct injected, turbocharged engines. An LSPI event typically happens at low engine speeds when under load. The air-fuel mixture ignites before the spark plug fires. This pre-ignition event can result in high cylinder pressures and engine knock. It can also damage the piston and spark plug.

There are two theories behind LSPI being investigated. The first is that a hot spark plug or area of the piston ignites the fuel mixture early. The second theory postulates that droplets of oil that are either deposited on the walls or trapped in the piston rings auto-ignite before the spark plug energizes.

The second theory assumes that the higher compression ratio and forced induction create the “perfect storm” of a richer mixture and higher temperature/pressure that leads to the conditions that cause a pre-ignition event.

The LSPI conundrum comes down to the volatility, or the potential to ignite, in the combustion chamber. Engine oil companies are focusing on the detergent and additive packages to fix the problem.

What some oil companies are reporting is that oils with high levels of detergents like calcium can promote LSPI. Other detergents and friction modifiers can help prevent LSPI. GF-6 oils will help to address this problem. Many automakers like GM are introducing new oil standards, but all of the new standards will have one thing in common — a high-quality synthetic base stock oil. Both suspects in the LSPI problem have forced some manufacturers to add extra fuel to cool the combustion chamber under low engine speeds and high loads. This solution reduces the overall fuel efficiency of the engine.

Oil Jets and Volatility

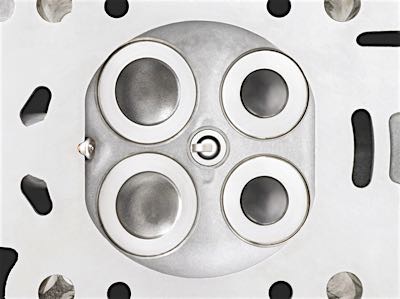

Many direct injection engines use oil jets to cool the pistons. The jets are part of the engine’s oiling circuit (mounted at the bottom of each cylinder), and they spray engine oil at the bottom of the pistons to cool the piston and the combustion carbon buildup on the head or crown of the piston.

If a low-quality, high-volatility engine oil is used with oil jets, it can result in carbon buildup and a higher-than-normal oil consumption rate. This is because low-quality oils have more volatility and are more likely to turn into vapor, or evaporate, when they make contact with hot engine parts. When the vapors are pulled into the PCV system, they can precipitate upon contact with the hot intake valves and cause carbon deposits.

Soot

On some gasoline direct injection engines, the amount of soot generated by the combustion process is greater than with port-injected engines. This is due to how fuel droplets burn inside the combustion chamber.

These soot particles can find their way into the engine oil. While one soot particle will not cause wear, clumps of soot particles will cause abrasive wear. Additives in oil can keep the soot particles in suspension, so they can’t clump together.

High-Pressure Fuel Pump and Oil

The main destroyer of high-pressure fuel pumps is delayed oil changes. Wear between the camshaft lobes and the high-pressure pump follower prevents the pump from generating enough piston movement. Less movement of the pump means less pressure. The ECM uses the camshaft and crankshaft position sensor inputs to synchronize the high-pressure fuel pump actuator with the position of each of the camshaft lobes. The ECM regulates fuel pressure by adjusting the stroke of the pump.

You should examine the lobes on the camshaft before installing a new, expensive high-pressure fuel pump. A lack-of-power complaint may improve from this measure, but will never be completely corrected.