Many people think the most important aspect of battery performance is Cold Cranking Amps – in reality, battery capacity is a misunderstood and often under-appreciated aspect, especially in modern stop/start engines.

The great radio commentator Paul Harvey famously closed his broadcasts by saying, “And now for the rest of the story.” In the automotive world, battery performance is normally measured in cold-cranking amps (CCAs). But, as you might suspect, “the rest of the story” is that battery capacity plays a far larger role in modern stop/start engine technology than does CCA.

Since stop/start engines can spend a lot of time key-on, engine off with a full accessory load, we’re beginning to realize that it takes a lot of battery capacity to keep those accessories running while the engine’s off. With “the rest of the story” in mind, let’s review how we measure cold-cranking amps, amp/hours and reserve capacity.

Always look at the label because AGM batteries can appear similar to flooded cell batteries.

BATTERY CORE TEMPERATURE

To begin, battery core temperatures are very important when discussing battery performance. While a shop’s room temperature might be 60° F, the battery’s core temperature can be 0° F, which can reduce available capacity by approximately 40% To avoid under-estimating battery state-of-health (SoH) or state of charge (SoC), the battery must “soak” for 24 hours at an ambient temperature before testing. In some cases, the test equipment must rely upon temperature compensation tables to adjust for unusually high or low battery temperatures.

CCA RATING

The SAE J537 CCA test requires a battery to maintain 7.2 volts at the B+ terminal for 30 seconds at a battery core temperature of 0° F. (-18° C.) at an amperage load equal to its rated CCA. But the problem with the SAE J537 rating is that most on-board electronics can’t function at 7.2 B+ volts. To address this issue, the DIN CCA test raises test thresholds to 9.0 volts for 30 seconds and 6.0 volts for 150 seconds.

CCA also doesn’t directly indicate the storage capacity of the battery, which is why batteries are additionally rated in amp/hours and reserve capacity ratings.

AMP/HOURS

Amp/hour ratings indicate the approximate storage capacity of a battery by multiplying amperage and time. Because high discharge rates distort test results by increasing battery core temperature, battery manufacturers rate amp/hours at relatively low discharge rates. To illustrate, a 60 amp/hour-rated battery will discharge one amp per minute or 60 amps/hour. A 75 amp/hour battery will discharge 1.25 amps/minute or 75 amps/hour.

RESERVE CAPACITY

Reserve capacity indicates how long a battery will power a vehicle if the charging system fails. The conventional definition of reserve capacity is how many minutes a fully charged 12-volt battery with a core temperature of 80° F. can deliver 25 amps until the terminal voltage is reduced to 10.5 volts.

Back in the day, 25 amps would be enough to keep a vehicle running with a full accessory and exterior lighting load. Today, that load value should be increased to at least a 50-amp discharge rate to compensate for all of the accessories and lighting demands.

CONDUCTANCE TESTING

Battery conductance testers measure internal plate resistance to determine battery state-of-health (SoH), which is especially effective for testing partially discharged batteries. Since the battery’s core temperature affects testing outcomes, correct CCA and core temperature must be entered before testing can take place. Testing outcomes are generally expressed as plate resistance values and percentages of rated cold-cranking amps.

LOAD TESTING

Adjustable carbon-pile load testers require a state-of-charge (SoC) of at least 75% and the battery core at room temperature. Before using a carbon pile tester, divide the rated CCA of the battery by two. Using a 500 CCA battery as an example, load-test the battery for 15 seconds at a 250-amp rate. A good battery will maintain at least 9.6 volts at B+ after load testing.

While conductance testing is more convenient in a production work environment, carbon pile load testing is the most accurate for determining the battery’s state of health. A combination of the two tests will usually detect all battery defects.

MODERN STARTING SYSTEMS

Cranking amperages have been dramatically reduced since the introduction of permanent-magnet, reduction gear starters, electronic fuel injection, and smaller displacement engines. The current reality is that, while a modern engine needs only a few cranking revolutions and a few CCA to start, amperage loads associated with supporting key-on, engine-off electrical systems have dramatically increased.

STOP/START TECHNOLOGY

The latest drivetrain innovation is the stop/start vehicle that shuts the engine off when the vehicle is stopped with throttle released and service brakes applied. When service brakes are released and the throttle is applied, the engine automatically restarts. The ultimate goal of stop/start technology is to increase fuel economy and reduce gross exhaust emissions by reducing engine run times.

But stop/start technology places unique demands on the starter battery. First, the battery plates must endure repeated rapid charge and discharge cycles. Second, the battery must supply enough reserve capacity to operate an electric water pump, which is required to circulate hot coolant through the heater core.

It must also operate the air conditioning compressor and HVAC blower with the engine off. If that isn’t enough, the battery must also supply current to accessories like heated windshields and seats, “infotainment” systems, windshield wipers, and exterior lighting with the engine off.

FLOODED CELL BATTERIES

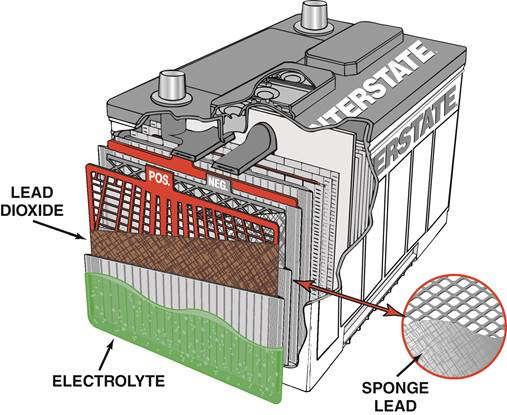

Conventional flooded cell, lead/acid batteries have started engines for over 100 years. In brief, flooded cell technology inserts separators between positive-charged and negative-charged plates to prevent them from shorting together.

Both plates and separators are suspended in a sulfuric acid solution that’s about 1.250 times heavier than pure water.

The downsides of flooded cell battery designs include their inability to endure rapid charge and discharge cycles and to endure sustained deep-cycle discharges caused by heavy amperage drains.

AGM BATTERIES

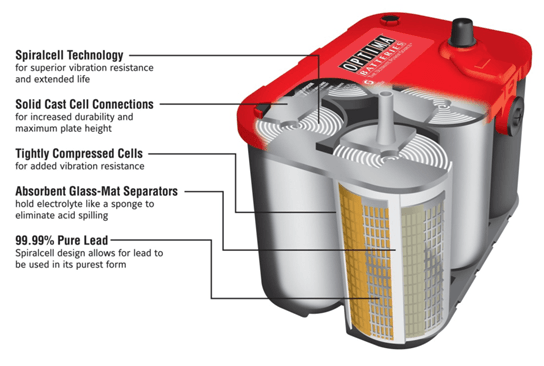

In contrast to flooded cell, Absorbed Glass Mat (AGM) batteries are more adaptable to stop/start technology due to a far greater range of performance. Such performance is attained by placing an electrolyte-saturated fiberglass mat between the positive and negative plates which simultaneously separates the plates and keeps the plates saturated with electrolyte.

AGM batteries can be configured into cylinders by spooling the glass mat and positive/negative plates together into a spiral or by sandwiching the glass mat and plates into rectangular cells similar to flooded cell batteries).

Glass-mat design features also allow an AGM battery to resist vibration and to rapidly alternate between discharge and recharge cycles without developing abnormal plate wear.

A major advantage of AGM batteries is their ability to produce high cranking amperages and maintain high reserve capacities at cold temperatures. AGMs also can be operated in a partial state of charge, which allows vehicles equipped with regenerative braking to use the vehicle’s inertia to help recharge the battery.

The main disadvantage of AGM technology is their vulnerability to over-charging and overheating, which can ruin glass mat separators and battery plates.

And Now…The Rest of the Story

Today, it’s much simpler to use your enhanced scan tool to extract battery and starting/charging system codes and data, all without opening the hood or your toolbox.

For example:

- Remember that increasing charging voltage also increases amperage flow.

- Practically all modern vehicles attach an inductive amperage clamp to the battery positive or negative cable.

- The alternators in these systems generally include an internal voltage regulator that’s managed by the PCM.

- While on-board diagnostic strategies vary, the engine control module (ECM) monitors not only battery voltage, but also monitors amperage passing to and from battery B+.

- One objective of the ECM’s voltage control is to maintain zero amperage flow through the inductive amp clamp.

- The ECM might increase charging voltage if B+ falls below 12.8 volts.

- With the hardware already in place, battery diagnostics can be achieved by adding an algorithm to interpret data from the inductive amp clamp.

- Plate sulfation is indicated when the battery reserve capacity begins to fall short. The ECM can increase charging voltage up to ~15.0 volts to reduce battery sulfation.

- If the ECM “sees” a continuous low battery voltage accompanied by a high charging amperage, it might infer that the battery is developing a bad cell.

- If the ECM sees zero amps at 12.8 volts, it might assume the that battery SoC is normal and deactivate the alternator altogether.

- Battery “registration” is required for replacement batteries because, as the battery ages, the ECM increases charging voltage to overcome increasing plate resistance.

- Lacking registration, new replacement batteries will over-charge, which can shorten their service lives.