The ASE X1 Certification Test has a section (8 questions) focused on emissions system diagnosis. For that section, among other things, you will need to:

• Identify failed catalytic converter(s); determine cause of failure; determine needed repair.

• Identify failed oxygen sensor(s) (O2S/HO2S) component(s) and circuitry; determine cause of failure; determine needed repair.

• Inspect emission systems for evidence of tampering (missing/modified and/or improperly installed components); determine needed repair.

Before attempting to diagnose what appears to be an emission control problem, there are several checks you want to perform first. For one, make sure the engine is in sound mechanical condition and good running order. Isolating a faulty component is a process of elimination that may include electronic and dynamic troubleshooting.

Next, to reveal if any restrictions exist within the exhaust system, you’ll need to perform a vacuum test or backpressure test. After a restriction is discovered, the rest of the system must be inspected before moving to replace the catalytic converter.

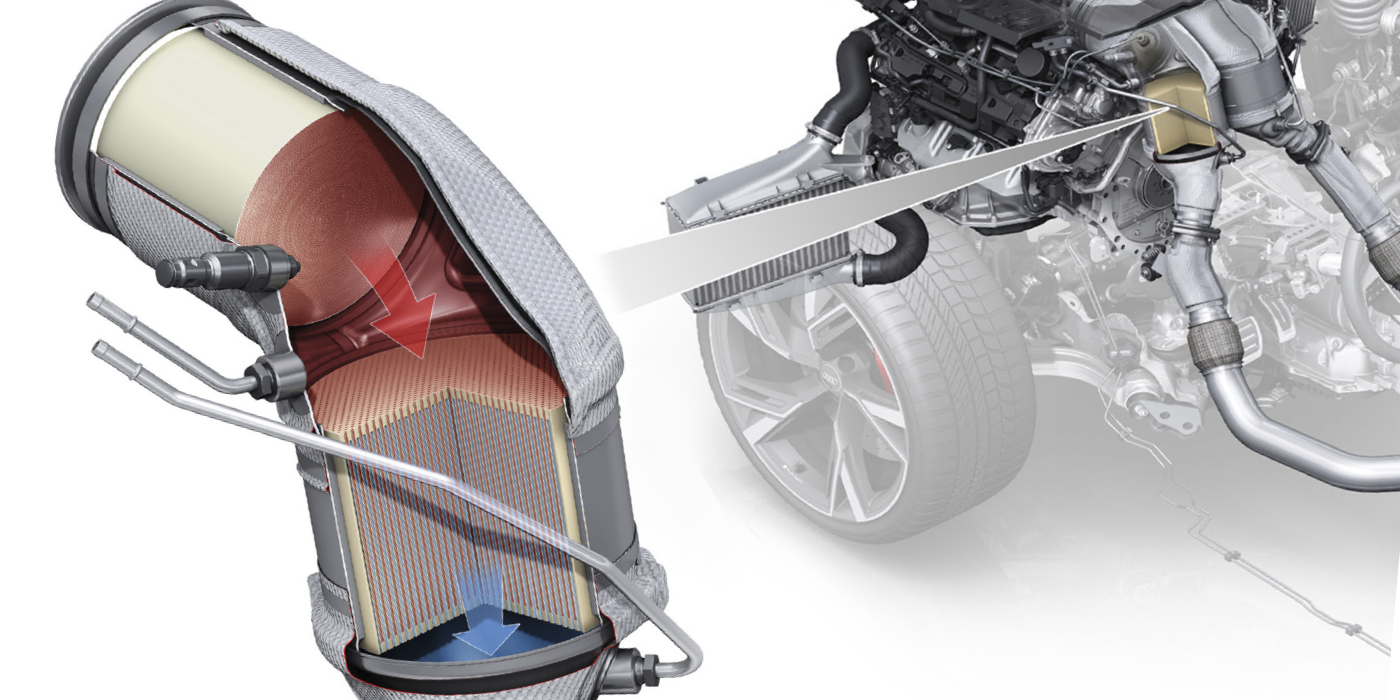

Catalytic Converters

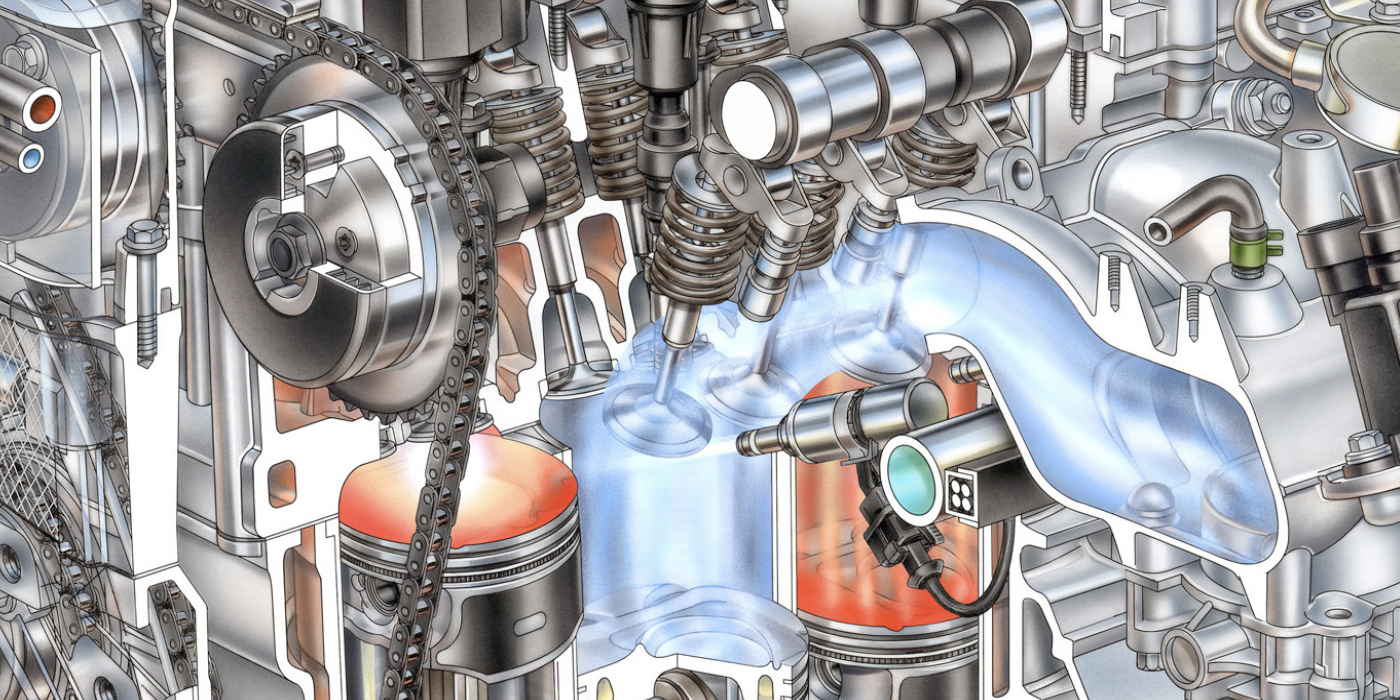

Like the engine, the three-way catalytic converter is sensitive to the air-fuel ratio. Maximum conversion efficiency is obtained when the stoichiometric air-fuel ratio is supplied to the engine.

The purpose of the three-way converter is to help clean the NOx, HC and CO emissions in the engine exhaust, hence the term “three-way.” Three metals (platinum, palladium and rhodium) are used as catalysts to promote the conversion of the emissions, which occurs in two stages:

In the first stage, the catalyst encourages NOx to break down into free nitrogen (N2) and free oxygen with the oxygen portion encouraged to further oxidize CO into the less harmful carbon dioxide (CO2).

In the second stage, the oxygen-enriched emissions pass over a second catalyst that encourages further oxidation of HC and CO into water vapor and carbon dioxide. Some earlier systems used a “mini Ox” converter upstream of the main catalyst.

Effective catalytic control of all three pollutants is possible only if the exhaust gas contains a very small amount of oxygen.

Service

Knowing that effective catalytic control starts with the amount of oxygen present, maintaining the proper air-fuel mixture in the engine is critical. When a lean air-fuel ratio is present for an extended period, oxygen content in a catalyst will ramp up. When a rich air-fuel ratio is present for an extended period, the oxygen content in the catalyst will be near zero. When either scenario occurs, the catalyst will fail to properly convert gases.

A converter’s operation essentially comes down to its ability to store and release the necessary amount of oxygen required to reduce chemical reactions. A deteriorating catalytic converter loses this ability to store oxygen over time. This oxygen-storing ability is a prime indicator of converter performance.

Oxygen Sensors

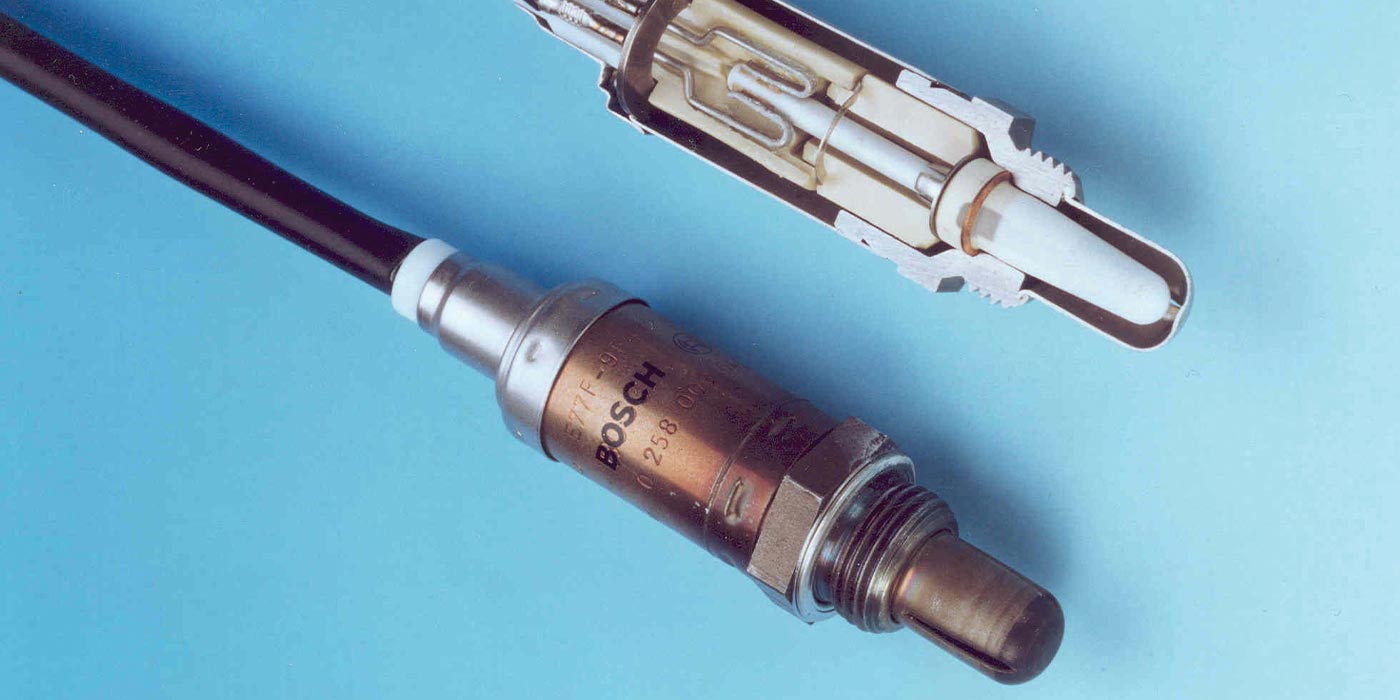

To check a catalytic converter’s efficiency, two oxygen sensors are required — one upstream from the converter and one downstream. This way, oxygen storage can be determined by comparing the two voltage signals.

Oxygen sensors monitor the oxygen content in the exhaust gases. You may hear an oxygen sensor referred to as a one-, two-, three- or four-wire sensor. All oxygen sensors have one wire that is called a signal wire that goes to the ECM. Ground can have its own wire on some sensors, but the ground of a one-wire sensor is the connection with the bung. The other wire or wires supply power for a heater.

As the PCM constantly adjusts the air-fuel mixture to maintain a stoichiometric ratio, the change in oxygen content is less noticeable downstream from the converter. Due to the effects of the converter, the oxygen content at the downstream sensor should be stable and the voltage output from the downstream sensor will change less rapidly.

To test converter efficiency, the PCM runs rich and lean air-fuel mixtures, to overburden the converter, and the H02S switches are counted. A switch is counted when an oxygen sensor signal goes from below the lean threshold to above the rich threshold. The switching ratio is determined by dividing the number of switches at the rear sensor by the number of switches from the front sensor. As catalyst efficiency deteriorates over the life of the vehicle, the switch rate at the downstream sensor approaches that of the upstream sensor.

There are several factors that can adversely affect the monitoring of catalyst efficiency:

• Exhaust leaks. Allowing excess amounts of oxygen to enter the exhaust system can mask a faulty converter.

• Fuel contaminants such as engine oil, coolant, phosphorus, lead, silica and sulfur can interfere with the converter’s chemical reaction, affecting the catalyst’s oxygen storage capacity.

Online ASE Test Prep: Oxygen Sensors

Need more guidance on the oxygen sensor’s role in diagnosing a misfire? Check out this handy training video from our friends at AVI: