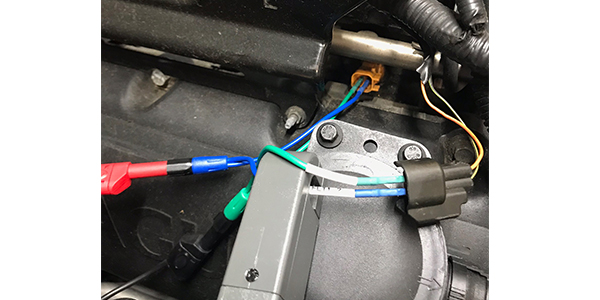

Fuel injector and secondary ignition waveforms can show the condition of the fuel and ignition system, and combined they can give you new insights on misfires and if they are related to the fuel or ignition system.

Scan tools can tell you if there is a misfire and which cylinder is misfiring. Rarely will you be able to determine if it is the ignition coil and spark plug or if the fuel injector is causing a rich or lean condition. With a scope that has the correct probes, it is possible.

Fuel Injectors

Most injectors use 12 volts to energize the coil, and the driver energizes the circuit by pulling it to ground. When the injector is energized, the voltage drops to almost zero. If it does not, it could mean an open or weak connection in the wiring harness or open coils inside the injector.

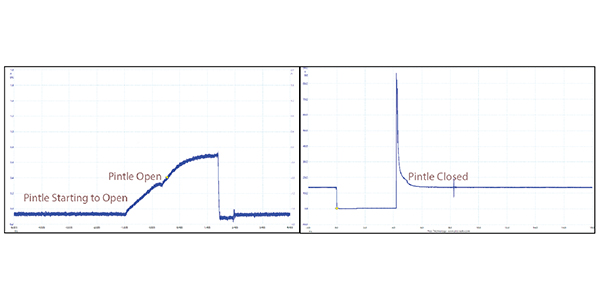

Current testing with an amp/current clamp can show you the injector opening. The current in the circuit should be a steady ramp. What you are seeing on the scope is the current ramping up to lift the injector’s pintle from the seat.

When there is enough current in the coil, the needle moves and fuel is injected into the engine. This event can be seen as a small rise in the slope. Where it appears in the slope is debatable. Many variables like injector specifications, fuel pressure and other factors can change the position of the event on the waveform.

If there is no current, the injector circuit could be open. If there is no ramp, but the current is flowing, it could mean the injector pintle is stuck open.

Measuring the voltage gives you a picture of what happens when the injector is closing. When the voltage is turned off, the needle starts to close. When it closes, it generates a voltage spike known as the inductive kick. This is a generated magnetic field collapsing in the coils. This spike can range from 50 to 100 volts. On the backside of the inductive kick, you may see a small positive hump or bump. This is the pintle hitting the seat of the injector and closing. This is a very powerful diagnostic insight.

Ignition

A secondary ignition waveform is not just about the coil, it is about the resistance of the air and fuel mixture inside the combustion chamber. When you are looking at a secondary ignition waveform, you need to be looking at the spikes and the hash in between. The first spike is where the coil discharges and the spark starts to jump from one electrode to the other. These spikes change depending on the resistance between the electrodes and the cylinder.

Now, imagine the air and fuel inside the combustion chamber as ohm resistors between the spark plug electrodes. If you increase the distance between the electrodes, you are increasing the amount of air between the electrodes and the value of the resistor between them. As cylinder pressure increases and fuel mixture changes, the amount of energy required to fire the plugs also increases. The resistance also changes because the amount of fuel changes the resistance.

Less fuel means higher resistance between the two electrodes of the spark plug. In the waveform, you can see this as the spikes change in height. Also, the burn line might be higher and shorter. But, the sign that there is a lean cylinder is the spike on the other side of the burn line. In some cases where the fuel injector is making the cylinder run lean, the two peaks might be the same height when the throttle is snapped or the engine is put under load. This is the leftover energy in the coil.

If the mixture is too rich, the resistance of the air and fuel mixture is lower than normal. This will result in normal burn time with no spike at the end.

A misfire is a misfire to an engine’s ECM. It typically can’t see what is going on in the cylinder and make the assessment if it is the coil or injector. Being able to look at both can help you diagnose the problem without even having to remove the spark plug.