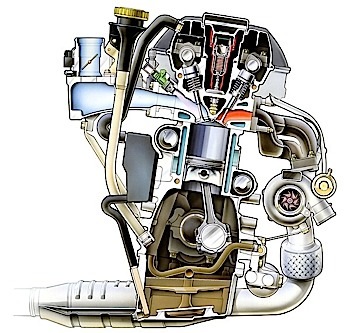

The basic concept of any forced induction system is to put more oxygen into the combustion chamber. More air in the engine means more power at the crankshaft. But, pressurizing the intake manifold means vacuum is replaced by pressure. This creates problems for managing vapors and pressure in the crankcase.

Natural Crankcase Pressure

On a naturally aspirated engine, the pressure in the crankcase increases and decreases with changes in engine load and speed. Gases from the combustion chamber can leak past the piston rings as the cylinder goes up during the compression and exhaust cycles.

As the piston travels down during the intake cycle, gases, oil and vapors in the crankcase can be sucked past the piston rings and into the combustion chamber.

Crankcase vapors are routed through the positive crankcase valve (PCV). The PCV valve is a simple spring-loaded valve with a sliding pintle inside. The system allows the vapors to be siphoned into the engine using engine vacuum.

Boosted Crankcase Pressure

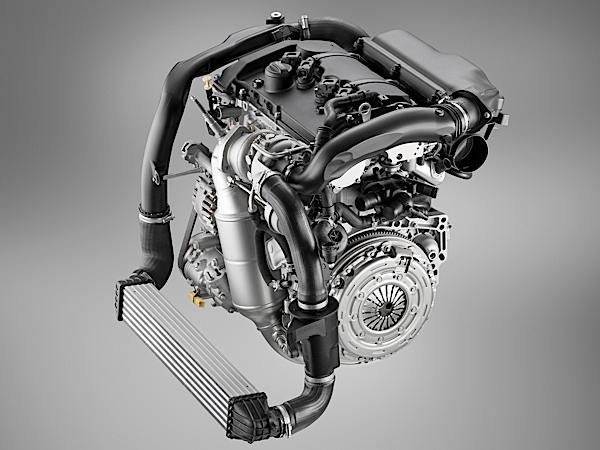

When an engine is turbocharged, the intake manifold is under pressure during most running conditions. The gas and oil bypassing the rings are still present. And, the pressure generated by the turbocharger can increase crankcase pressures. That’s when a more advanced PCV system is required.

Vacuum is present before the turbocharger. On some engines, the vacuum is greater than the vacuum generated by the pistons moving downward, but not all the time. Vacuum is generated only when the turbo is spinning. The area before the turbocharger is typically where the vapors from the crankcase are fed into the engine. Some turbocharged engines will feed crankcase vapors to the intake manifold with a bypass valve when the turbo is not creating enough vacuum.

Turbochargers do not like ingesting the oil that can be found in crankcase vapors. The oil can form carbon deposits on the vanes and housing and cause a loss of boost.

Modern turbocharged engines have large oil separators typically incorporated into the valve cover or on the side of the engine block. The crankcase pressure is not managed by a simple check valve. Pressures are monitored electronically or mechanically at both the crankcase and intake. The system directs the vapors to either before the turbo or intake manifold when the time is right.

These next-generation PCV systems can fail because they are exposed to high temperatures and combustion gases that can damage plastic, flexible diaphragms, and seals.

If the system starts to leak, it can allow unmetered air to enter the intake. This can cause misfires and lean codes. In some cases, the pressure generated from the turbocharger can find its way into the crankcase if the system has failed. This extra pressure can cause oil leaks. If the pressure is great enough, it can even restrict flow coming from the turbocharger oil return line, thereby shortening the life of the bearings.