The automatic transmission as we know it started as an option in the 1940s. In the past 70 years, it has evolved from crude two-speed to six- and even nine-speed transmissions. Also, better electronics and solenoids have been added. But the one thing that has not changed for transmissions is the need for fluid maintenance and the driver who always forgets.

The automatic transmission as we know it started as an option in the 1940s. In the past 70 years, it has evolved from crude two-speed to six- and even nine-speed transmissions. Also, better electronics and solenoids have been added. But the one thing that has not changed for transmissions is the need for fluid maintenance and the driver who always forgets.

Transmission fluid service has been a hot topic for engineers, drivers and shops. The biggest issue is that no matter the service or tools, it is impossible to replace 100% of the transmission fluid unless the transmission is disassembled.

New fluid can dilute and replenish the old fluid and hopefully return the condition of the fluid close to factory-fill conditions. But, if the second or third service is delayed, the condition of the fluid quickly goes downhill fast.

If the transmission is performing poorly before the service, it needs to be inspected and taken for a test drive. Always inspect and test drive a vehicle before performing an Automatic Transmission Fluid (ATF) Refresh procedure.

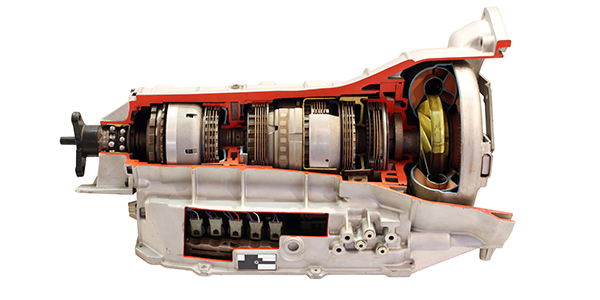

An OEM or traditional transmission service typically involves pulling the transmission’s pan, replacing the filter and replacing the fluid in the sump of the transmission. This type of procedure replaces a small volume of ATF, but the new filter can catch the fine debris that can become embedded in the friction materials of the bands and clutches.

Fluid exchange machines are another option that came out in the 1980s. These machines connect to the transmission cooler lines to create a bypass to exchange the majority of the fluid. This is very effective at replacing the majority of the transmission fluid. But, exchange machines and services have their drawbacks.

First, it can be difficult connecting the exchange machine to some late-model transmission lines due to proprietary fittings and new cooler designs. Second, the most expensive part of this service is the fluid. Some transmissions can hold 11 to 17 quarts of ATF.

The best option for vehicles that fall outside the factory service intervals is an ATF Refresh. First, old ATF is extracted through the dipstick tube or filler hole. Second, the same amount of fresh fluid is replaced. The ATF Refresh process is repeated during the next oil changes.

Eventually, the volume of fresh fluid replaces and dilutes the worn out fluid. ATF Refresh can keep and improve the ATF additive levels and performance.

ATF Refresh can be a very cost-effective method to maintain a high-mileage transmission on an older vehicle. These are the transmissions that you fear would fail if all of the fluid was replaced at once, or if the customer can’t afford a transmission service where the filter is serviced.

Filler Up! With a Scan Tool

No matter what type of transmission service is performed, the final level of the fluid must be set. If the vehicle does not have a dipstick, there is typically a process in the service information that needs to be followed.

If too much transmission fluid is added, the fluid might come in contact with rotating parts and aerate the fluid. Too little transmission fluid could cause heat transfer problems and air to get into the valve body.

Some of these filling procedures might require a scan tool. On some transmissions, the final level is set when the transmission hits a specific temperature that is indicated on a scan tool. On transmissions with level sensors, the final level is set with the sensor that is read by the scan tool.

No matter the method you use to service transmission fluid, it will not add friction material to the clutch packs or remove heat checking from metal surfaces damaged by improper maintenance or driving habits.