One of the worst failures that can occur inside an engine is a spun bearing. It can happen in a stock engine or race engine, gasoline engine or diesel engine. A spun bearing is bad news because it usually seizes itself around the crankshaft journal.

What happens next depends on the bearing’s location. Spun rod bearings are the most common failure. A spun rod bearing will tear up the big end bore in the rod, ruin the rod journal on the crankshaft, and sometimes break the connecting rod. That’s really bad news because a broken rod flailing around inside an engine can obviously do a lot of damage! A spun main bearing will tear up the main bore in the block but rarely will it cause the crank to fail. The damage is usually limited to the main journal surface on the crank and the main bore housing.

Various Causes

A spun bearing is usually the end result of a chain of unfortunate events. These include high operating loads, excessive heat and a loss of lubrication.

Spun bearings are often blamed on a loss of oil pressure, but there can be numerous contributing factors that eventually cause the bearing to seize and spin. Normally, bearings allow the crank to glide on a hydrodynamic film of oil between the bearing surface and journal. As long as there is a steady supply of clean, fresh oil flowing into the gap between the bearing and journal, everything is fine. The film only has to be a few microns thick to maintain protection. But if there is a sudden loss of oil pressure and flow, especially at high RPM, the protective film can disappear in an instant. Once that happens, you get metal-to-metal contact between the bearing and journal surfaces, which causes scuffing, increased friction and heat.

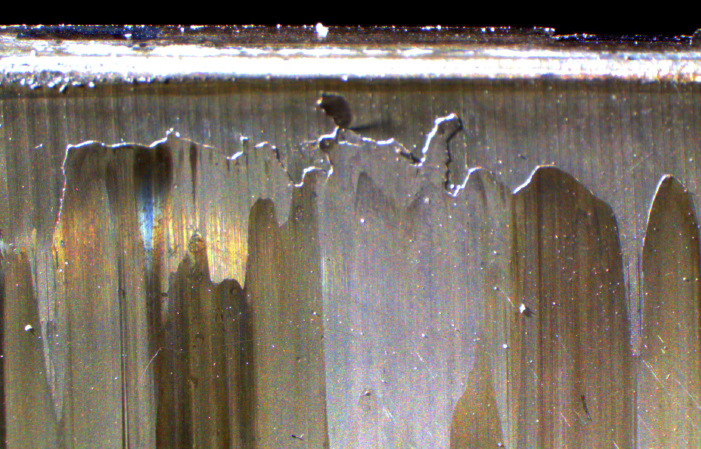

It doesn’t matter what type of bearing is involved, be it aluminum or a babbitt-faced tri-metal, because all types will start to melt around 450 degrees F or so. A babbitt overlay on a tri-metal bearing offers good seizure resistance, but once it goes away the copper layer underneath lacks seizure resistance. Consequently, if there is enough scuffing, friction and heat due to a lack of lubrication, the bearing will melt, smear and stick to the crank journal. At that point, you get a seized or spun bearing with whatever additional damage it causes.

Although this may happen suddenly, often there has been an ongoing lubrication problem that has caused a bearing to scuff, run hot and overheat. This can discolor the crank journal and/or blacken the big end of the rod. So if you tear down an engine and see such signs of overheating, it’s a solid clue that the engine has an oiling issue that needs to be identified and corrected before it’s put back together.

Contributing factors that can cause oil pressure and lubrication problems in an engine include:

- Low oil level in the oil pan due to leaks, maintenance neglect or improper filling.

- Oil pump cavitation and aeration at high RPM due to pump design, restrictions in the pump inlet tube or pickup, or oil sloshing away from the pickup in the bottom of the pan due to extreme cornering, acceleration or braking forces.

- Blocked or partially blocked oil gallery or oil filter.

- Bearings installed incorrectly (oil holes do not line up with the gallery holes). This is especially important with cam bearings that can be easily misaligned.

- Bearing clearances too tight for the oil viscosity being used. Late-model engines such as a Chevy LS or Ford modular V8 with tighter main and rod bearing clearances of .0015˝ to .002˝ usually require a thin multi-viscosity motor oil such as 5W-20. Fill the crankcase with a relatively thick racing oil and you’ll have problems right from the start. Tighter bearing clearances require thinner oils while looser bearing clearances of .003˝ to .004˝ in “old school” motors and race motors require thicker oils (20W-50 or 50W) to maintain the protective oil film between the bearings and their journals.

- Misalignment of the bearing shell and crank journal.

- Mistakes made when machining housing bores or crank journals (wrong diameters).

- Cold starts, especially in close tolerance racing engines running thicker oils.

- Extremely high bearing-to-crank loads due to lugging, detonation or high boost or nitrous applications.

Reduce the Risk

If an engine has suffered a spun rod or main bearing, and the engine is rebuildable, it will require resurfacing the crank journal, possibly re-machining the main bore or big end rod bore (or replacing the rod) depending on the damage that has occurred. The replacement bearings will also have to be correctly sized to compensate for any changes in bore diameter so they fill fit properly when installed. New main and/or rod bolts are also recommended. Don’t reuse torque-tow-yield (TTY) bolts because they stretch when tightened and may break if reused.

Follow basic assembly rules such as pre-lubing the front of the bearings with assembly lube or oil, and making sure the backs of the bearing shells are clean and dry.

If you are building a race motor, use performance bearings rather than stock bearings. Race bearings have stronger materials that can handle higher loads, and they have more eccentricity to help form the oil wedge that provides hydrodynamic lubrication, especially at higher engine speeds.

Make sure the engine has no oiling issues and is capable of achieving and maintaining good oil pressure. Check the oil pump for wear, damage or excessive clearances and replace as needed. Make sure the oil pump pickup tube is secure and the pickup screen is unobstructed and located at the proper height above the bottom of the oil pan. If you’re building a race motor, make sure the oil pump can deliver the oil flow the engine will need at high RPM.

Make sure the oil pan is filled with the correct amount and viscosity of oil before the engine is fired up. Also, prime the oil system to prevent a dry start. And make sure the engine is getting good oil pressure once it is running.