Selling a replacement serpentine belt at 90,000 or 100,000 miles is easy. But, making that new belt go the same distance as the original can be more difficult. With zero miles on an odometer, the belt is operating in the best possible environment. The plane of the belt pulleys is properly aligned and there are no leaks. And, the tensioner is new and the spring and dampening elements are not worn out.

But, as the belt operates, it is subjected to heat from the engine and heat generated by the friction between the belt and pulleys. Dust, sand and other debris get in between the belt and pulleys and cause wear. Air, oil and other fluids attack the chemical composition of the belt, causing it to break down and lose its ability to grip the pulleys.

The vehicle could have a replacement water pump, alternator or power steering pump. Any of these items will change the plane and alignment of the pulleys and how the belt rides in the grooves. This can prevent the new belt from lasting as long as the original.

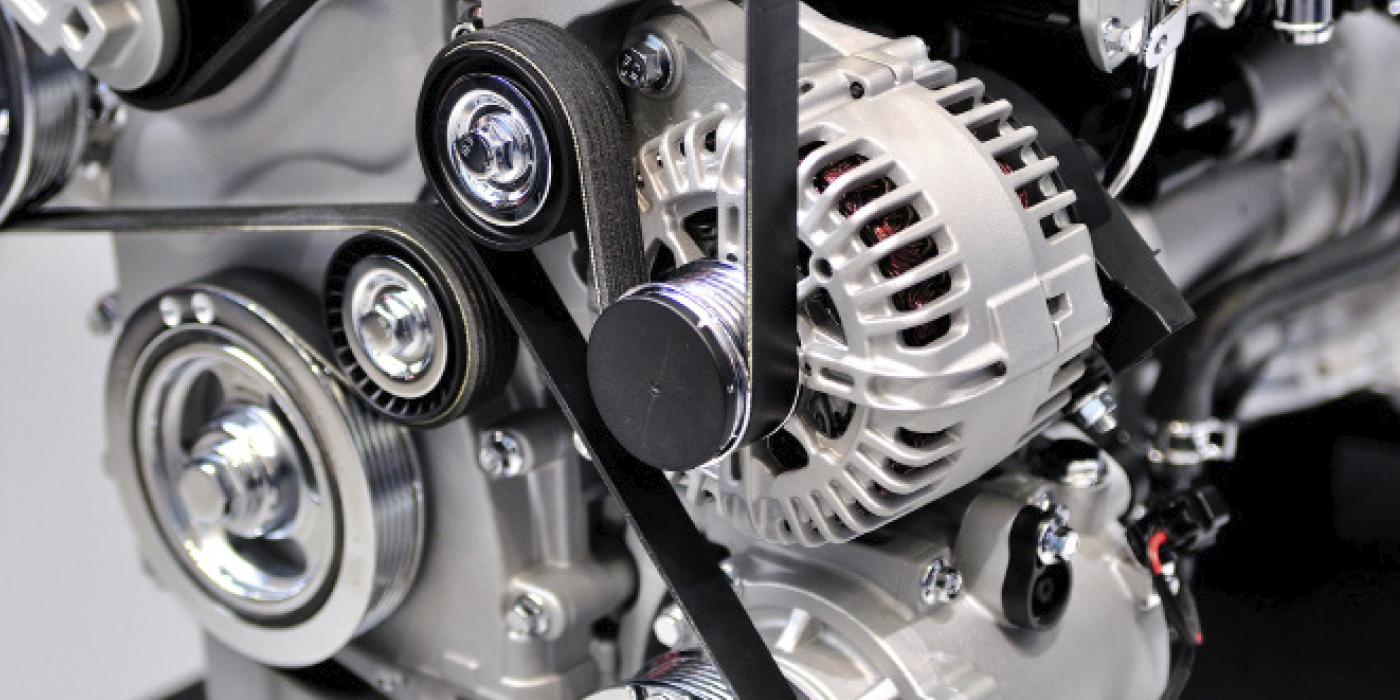

By 90,000 miles, the tensioner is worn on most vehicles. The tensioner is more than a spring — inside is a friction disc or, on some engines, a hydraulic or rubber-filled cylinder that acts as a damper to control belt tension as the crankshaft rotates. When the tensioner’s dampener wears out, belt tension can increase because the force of the spring is not dampened. This can increase wear on the new belt.

Bearings inside the tensioner and idler pulleys can wear out over time and cause noise. In extreme cases, they can cause alignment issues. Recommend replacement if you see any leaking grease. Failed pulleys will make a chirping and/or grinding noise. They can also create an alignment problem and increase belt wear.

With more than 350 million of these on the road, the decoupler pulley is a maintenance item. A decoupler pulley does two things. First, it decouples the alternator from the engine and belt so that the alternator does not cause a parasitic load on the crankshaft. Second, it absorbs crankshaft power pulses. A decoupler pulley can wear out in as little as 80,000 miles, depending on the design.

Belt Options

In the past (and even today), a serpentine belt was packaged in a cardboard sleeve and hung on a wall at the parts store. Now, there are kits that include the belt, tensioner and even decoupler pulleys that are vehicle specific. This belt option might be more expensive, but it is more economical because replacing the tensioner and associated components can make the belt last just as long as the original.