Timing is everything and being off even the slightest amount can be disastrous.

Let’s face it: timing used to be relatively easy. These days, however, as with most every other engine component, the technology and innovation that leads to more fuel efficiency and performance also means increased complexity with timing components.

You’re already facing challenges in understanding late model chain drive timing systems and how to properly set up the camshaft, crankshaft and balance shafts along with the electronic sensors used by the powertrain system (aka, the computer) to achieve optimal engine performance – guess what? That’s unlikely to change.

“We’ve seen a shift away from conventional three-piece timing sets,” explains one manufacturer. “As such, the more modern timing setup – with the sprockets regulating the firing of the engine – will continue to become more critical.”

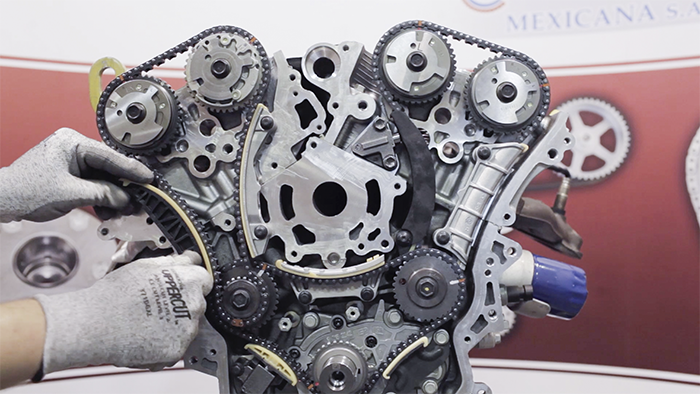

Take the GM V6, 3.6L engine, for example. Like some bizarre math word problem, this DOHC, four camshaft engine uses two idler sprockets requiring three separate timing chains to operate the timing system. There are four camshaft sensors and a crankshaft sensor used to operate the VVT system – the engine requires 15 pieces needed to service its timing system, not including any of the VVT components.

In general, overhead cam engines do pose greater repair complexity. Certainly newer engine designs such as Ecoboost, Duratec, Hemi and emerging diesel platforms will require specialized knowledge with regard to timing.

Overall systems have gotten more complicated, and depend heavily on hydraulics and the hydraulic system to support the stability of the system. This puts more demand on the engine’s hydraulic system, and it’s up to the timing system to keep it all stable.

It’s a very interdependent system and, explains one of our experts, when this stuff decides to fail, it’s the perfect storm.

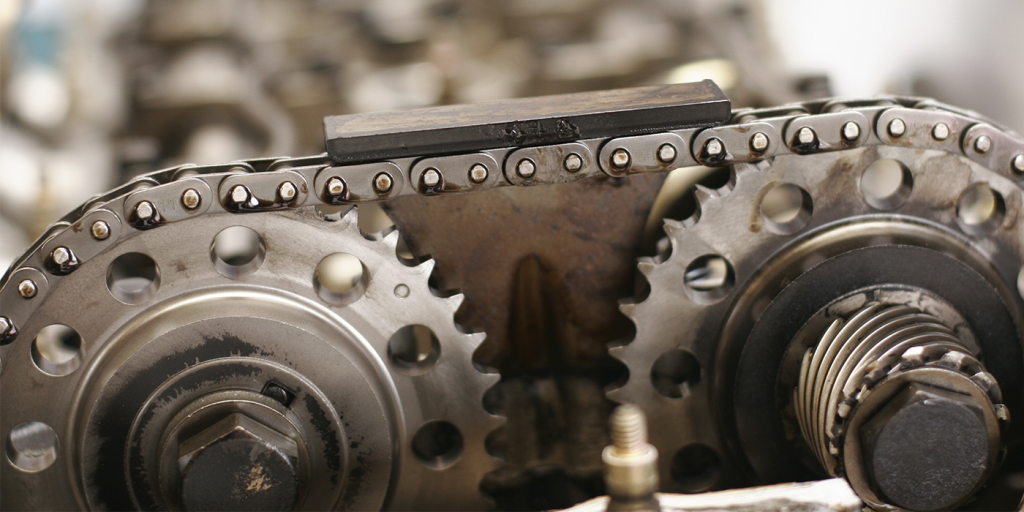

Many people think chains are pretty simple components but the reality is there’s a lot of moving parts, with a different material for each component. Oil quality is absolutely huge when it comes to the life of a chain and the rest of the components that are just along for the ride. The tensioner is going to keep tensioning. Usually, they’ll keep tensioning all the way to the end of their range of motion where they have nothing else to give, and then finally everything gets beat up because the chain is whipping around and crashing into everything.If a customer drives to that point of audible rattle and and ignores the check engine light it’s really too late.

“Unlike older engines, late model applications use multiple camshafts and balance shafts requiring more sensor input to the computer to lower emissions while gaining horsepower and torque,” says one timing component manufacturer. “This also controls VVT operation. A check engine light can easily be triggered if new timing components are not properly installed and every engine is a little bit different.”

All of them have chain stretch and/or timing correlation codes that will be displayed before it gets bad enough to fail in a high feature V6. Typically, these will warn the driver, who will learn the engine can no longer maintain its valve timing due to chain stretch. These codes are not thrown because of mileage but because of maintenance.

It’s critical that the engine is operated using the correct type of oil and oil viscosity.

Most tensioners have a built-in mechanical ratchet mechanism as well, so as long as things are within that tensioner’s range of motion and the fatigue life of the chain, everything functions with stability. It’s when the chain’s link gets to a point where the tensioner can no longer take all the slack out of the system, that it starts damaging guides, the chain starts whipping around and its start breaking other components.

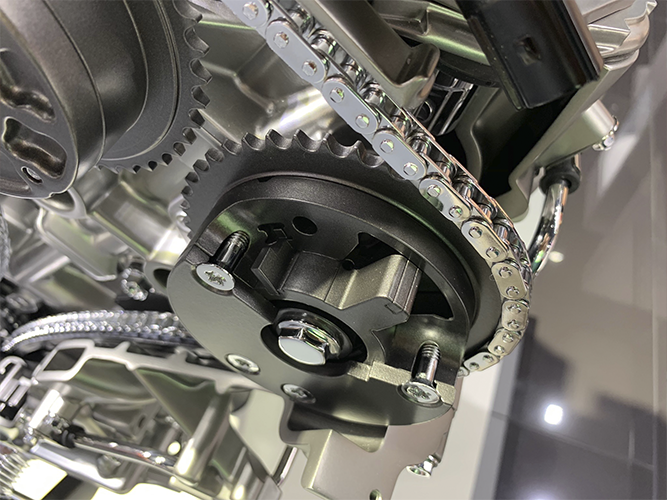

Experts say today’s diagnostic capabilities mean technicians don’t need to wait for rattles or the sound of the chain hitting the timing cover to know that a chain is stretched out and the tensioner can no longer take up the slack. However, the importance of oil quality cannot be overstated. The tensioners have very small oil passages and check valves that can become plugged, reducing the amount of pin pressure being applied to the tensioner arm or chain.

When a timing system that uses hydraulic tensioners fails, other areas of the engine must be checked before installing new timing components. The overall condition of the engine has to be good. A worn engine will have problems with oil pressure whether cold or hot, during idle or while driving and could have sludge and dirt built up inside it. A low oil level can introduce air into the oiling system and cause problems with these tensioners resulting in an intermittent pounding effect on the chain instead of constant steady pressure.

Because clogging of these tensioners and VVT solenoids is such a dangerous threat, some OE manufacturers have started putting internal check valves along with oil screens inside of the tensioners and solenoids to extend life. Others are using what’s called a ratchet design that holds tension on the tensioner pin maintaining tension on the chain when the engine isn’t running.

With high feature V6 engines, fatigue life is dependent on how the engine was maintained and the mileage of the vehicle. Experts predict initial failures between 80,000 and 150,000 miles – poorly maintained at the bottom and better maintained near the top of the range.

Worthwhile Repair Opportunity

However, the cost of the repair is worth it for the value of the vehicle, say experts, because with proper maintenance of the rest of the components in the engine and transmission means the vehicle will likely hold up for many tens of thousands of additional miles.

So, even though it’s a lot bigger job than with timing belt, it’s still within reason. “A high feature V6 job is not that difficult of a job,” explains one timing expert. “There’s some labor hours to it – probably 8 to 12 hours. It’s going to be an expense, but it is still very doable and it’s not that difficult.”

One of the keys to this platform, he says, is that the high feature V6 is a good application for the aftermarket.

“We’re not chasing down a flawed design like the Ford 4.0L – in that case we had OE failure as well as aftermarket failure. That was especially bad for the aftermarket businesses because they would do the repair and the thing would still fail.

The bottom line, experts say, is that you must use the correct oil type and viscosity. Remind your customers that regular oil changes are more than just a nice idea.