Drum brakes that occasionally lock up should not be ignored, but a relatively recent drum-brake-lockup condition is often dismissed because it doesn’t happen all the time. Since it’s usually not present by the time a technician gets to look for its cause, it’s often tempting to suggest the customer simply live with it.

But the condition, sometimes called “drum brake morning sickness,” shouldn’t be ignored. Unlike customary causes of drum-brake lockup, like worn backing plates where shoe table edges contact the backing plates, there’s usually no visible evidence of this condition’s cause when the customer reaches your shop. This is one of many situations where getting complete information from the customer is vital in determining what’s going on.

WHAT CAUSES IT

Factors that can cause short-term, early in the driving day, drum-brake lockup include dampness, or high humidity (causing light corrosion), and excessive heat. This condition is not uncommon in Ford F-Series pickups with hard-working rear drum brakes in rainy areas (though it’s not limited to Fords or trucks.) It’s also more likely when using brake shoes with a high metallic content. And if the drums are either new or freshly resurfaced – so there’s little or no friction material embedded in them – the condition is even more likely, as the surfaces may develop a thin film of corrosion. This isn’t good news if you’ve just done a rear-axle hang-and-turn job: The customer knows you were the last one inside the drums!

CONTROLLING THE PROBLEM

CONTROLLING THE PROBLEM

You can’t do much about rain or high humidity, but you can help lessen drum and shoe surface corrosion by verifying that all adjustment slots or knockout holes in backing plates or drums are properly plugged. And verify the lining to drum clearance and the parking brake adjustment are within specification.

If drums are new or just resurfaced, let the customer know the condition should improve after a short break-in. You may even suggest a few gentle stops or snubs (light brake applications slowing the vehicle without coming to a complete stop) to warm, burnish and help dry the brakes, first thing in the morning.

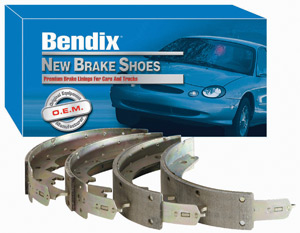

But prevention is your best strategy, and this is a matter of using quality parts: Select quality drums, and lubricate backing-plate ledges sparingly with Bendix Ceramlub brake lubricant. And make sure the brake shoes you use aren’t prone to surface oxidation: The friction formulation in Bendix brake shoes has been engineered to help prevent the formation of grabby surface corrosion, even in humid conditions.

Courtesy of Bendix by Honeywell.

Courtesy of Bendix by Honeywell.

For more information and brake tips, visit www.bendixbrakes.com.