Fine particles can enter a hydraulic system because of mechanical stress on the steering components. As a consequence, it is recommended to flush the entire hydraulic system when replacing the power steering pump.

A few vehicle manufacturers have installed a drain bolt in the area of the steering gear. The disadvantage is that it is not possible to drain all the fluid here. A residual quantity always remains in the system.

Procedure:

1. Raise the vehicle’s front wheels off the ground. Raising the wheels will allow for lower resistance (in steps 9 and 12) when turning the wheels back and forth while flushing the system. It will also prevent the hydraulic fluid from foaming.

2. Remove the power steering reservoir cap.

3. Remove the return line on the reservoir, making sure to collect all the fluid being drained out.

4. Disconnect the feed line from the reservoir and remove the reservoir from the vehicle.

5. With the reservoir removed, clean the inside with a suitable cleaner. Brake cleaner is recommended. If equipped with an in-line filter, be sure to clean or replace the filter.

6. Reinstall the reservoir and attach the fluid feed line, but do not attach the return line. With a suitable plug, plug off the location on the reservoir where the return line should be connected.

7. Fill the reservoir with the correct fluid, allowing the fluid level to stabilize. Once the fluid has stabilized, start the vehicle.

8. With the engine running, collect the fluid that will be flowing out of the return line.

9. Keeping the engine running, turn the wheel back and forth from stop to stop. Do this 10 to 12 times until the fluid runs clean.

Very important: Always make sure to keep the reservoir full. Do not allow the reservoir to run dry as this will damage the pump and create air in the system.

10. Once the system is flushed, turn off the engine. Remove the plug on the reservoir and reconnect the return line. (Collect the fluid that will run out of the reservoir when the plug is removed and dispose of properly.)

11. Top off the reservoir with additional, clean fluid and allow fluid level to stabilize.

12. Once complete, start the engine and turn the wheel stop to stop 20 times to bleed air from the system. While the system is being bled, make sure the fluid level does not go below the fill line.

13. Lower the vehicle, verify the fluid is at the correct operating level, then reinstall the power steering reservoir cap.

14. Check for any leaks and test drive to verify proper operation.

Important!

It is essential to comply with the vehicle manufacturer’s installation instructions and only to use the hydraulic fluids approved for the respective vehicle. The specification is found in the owner’s manual.

Important!

Hydraulic fluid may not enter the soil. Disposal must take place via the supplier of the materials or a special refuse collection point.

Courtesy of Schaeffler Group USA.

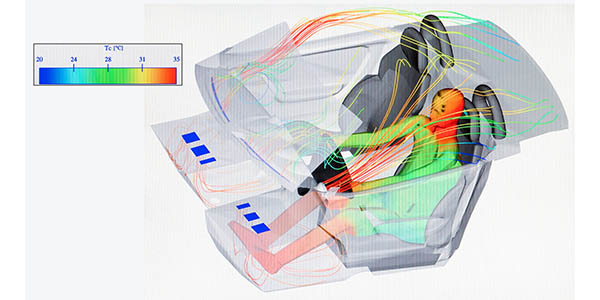

HVAC Sensors: More Than Just Temperature

When a driver sets a temperature in the control head of an HVAC system, what does it mean to the vehicle? Seventy-two degrees could mean many different settings depending on the outside temperature, humidity and even the position of the sun.

When a driver sets a temperature in the control head of an HVAC system, what does it mean to the vehicle? Seventy-two degrees could mean many different settings depending on the outside temperature, humidity and even the position of the sun.

When a passenger decides that 70 degrees is a better temperature for their zone, things get even more complicated. Automatic Temperature Control (ATC) systems require a complex array of internal and external sensors that include ambient air temperature sensors, interior temperature sensors, outlet duct and evaporator temperature sensors, pressure sensors, humidity sensors, blend door position sensors and sunload sensors.

Nearly 5,000 To Participate In Auto Value, Bumper To Bumper ‘Festive Walk’ To AAPEX 2018

On Thursday, Nov. 1, nearly 5,000 Auto Value and Bumper to Bumper automotive professionals wearing matching yellow shirts will begin their “festive walk” from the Mirage hotel to AAPEX 2018 at the Sands Expo, temporarily shutting down the busy Las Vegas Boulevard along the way.

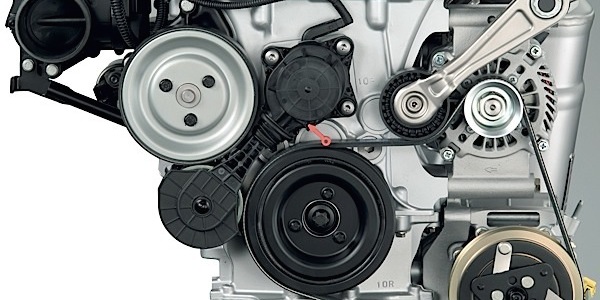

Drive Belt Checklist: What Are You Missing?

You might have only one chance to sell a customer a new serpentine belt. With belts lasting roughly 90,000 miles, proper inspection at the time of failure is critical not only for selling the belt, but also for ensuring add-on sales and better customer satisfaction.

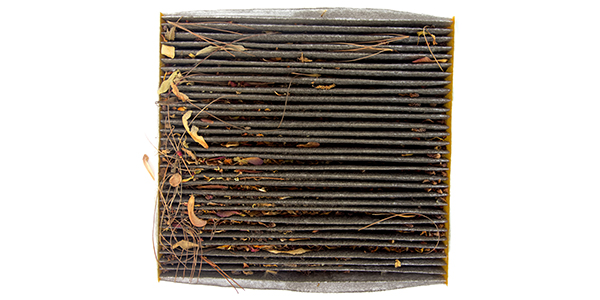

VIDEO: Using Airflow To Sell Cabin Air Filters

Andrew Markel introduces an inexpensive tool that can assist in selling cabin air filter replacements. Sponsored by Auto Value and Bumper to Bumper.

Air Conditioning Odor Causes

Air conditioning odors typically result from the uncontrolled growth of bacteria and other microorganisms in the evaporator. Research by independent laboratories has found fungi such as Aspergillus, Cladesporium, Penicillium and others growing on cooling coils and other A/C system areas.

Other Posts

Bolster Your Steering and Suspension with Delphi!

A vehicle’s steering and suspension system is integral to its ride, handling, safety, and must always be up to the job–that’s where Delphi comes in. All Delphi chassis parts undergo rigorous dimension, material, durability, temperature, and performance tests to ensure they meet or exceed OE specifications at every turn. Because Delphi’s debut in steering and

Climate Control Modules

HVAC control modules may fail when the contacts and switches become inoperable. Sponsored by The Group Training Academy.

Dorman Launches 300+ New Products In November

Among the new products is an OE FIX climate control module designed to fit 1.7M Chevrolet Express & GMC Savana vehicles.

Curing Springtime Air Conditioning Smells

Air conditioning scents can come from a host of things.