There has been some confusion about the function of the threaded portion of the inside diameter of certain spiral reamed valve guides.

The spiral inside the guide is there to hold oil and aid the lubrication of the valve during engine operation. To prevent excessive oil consumption, the threads stop approximately 7 to 10 mm from the bottom (combustion chamber) of the guide in most applications. However, there are applications where the spiral-ream is the total length of the inside diameter.

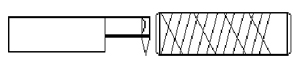

Some manufacturers supply valve guides with a single-point boring tool (Figure 1), which can be dragged backwards after spiral reaming is completed. This process creates a secondary cut or "tool return" in the spiral-reamed finish. A misconception is that the secondary groove, or tool return, sometimes seen in the spiral performs a lubrication function. The secondary groove is merely a manufacturing step and offers no benefit towards lubrication. This process is an optional step in spiral reamed guides and is usually determined by the manufacturer. Whether the tool return is present or not, this does not mean the guide is of lower quality or the spiral reaming will not perform its lubrication function.

In most cases where the tool return is present, it is a manufacturing process that enables the manufacturer to increase production time. Spiral reamed guides are offered on many applications but not all. Refer to your valve guide manufacturer to see if the guide you are using is spiral-reamed.

Source: S.B. International.