Whistling sounds have been reported coming from some 2007 Chrysler 3.7L engines. The intake-to-throttle-body joint may be the cause of the “whistle-like” sound.

This repair procedure involves applying a thin bead of RTV to the intake manifold-to-throttle body joint. This information applies to vehicles equipped with a 3.7L engine built on or before March 12, 2007.

There have been reports of vehicle owners who experience a slight “high frequency (pitch)” whistle-like sound while driving. This sound is not loud and may not be noticeable to most drivers. The sound can occur at any ambient or engine operating temperature. The whistle-like sound is most noticeable under load, with a light throttle, and between 1,200 and 2,000 engine rpm. Please note, very few vehicles will exhibit this condition.

If the customer experiences the above condition perform the following repair procedure.

1) Remove the Electronic Throttle Control (ETC) throttle body from the intake manifold.

1) Remove the Electronic Throttle Control (ETC) throttle body from the intake manifold.

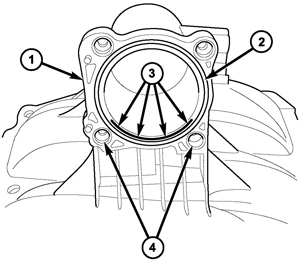

2) Apply a very small diameter bead (1 mm) of RTV to the intake manifold-to-throttle body joint. The RTV is to be applied to the lower section of the joint between the lower two throttle body bolt attachment holes (Figure 1). A very small amount of RTV is needed to seal the slight space/gap on the inner surface of the joint. The gap was created by a slight taper in the intake manifold joint surface. Do not apply an excessive amount of RTV to the joint. And do not over-torque the throttle body bolts, as it may cause damage to the throttle body.

3) Install the ETC throttle body to the intake manifold. Tighten the throttle body’s four attaching bolts to 60 in.lbs. (7 Nm). Wipe off inside joint of any excess RTV that is squeezed out.

4) Reassemble the remaining engine components.

This information was provided by the Automotive Parts Remanufacturers Association (APRA). For more information on technical bulletins available through APRA, call (703) 968-2772 or visit www.AutoBulletins.com.