Vehicles/engines affected: 2005 up to 2006 Boxster (987)/Boxster S (987) with M96 engine.

A screeching noise can be heard from the engine at around 2,000 rpm during the engine warm-up phase. In many cases, the noise is an indication that the engine or oil pump has been changed. The noise is caused by the control piston in the oil pump.

Note: In the event of a complaint, a modified control piston must be installed in the oil pump cover.

Date of Introduction:

Engines manufactured since Dec. 5, 2005 as of engine numbers:

M96.25 61 6 04763

M96.26 62 6 03668

Work Procedure for Technicians:

1. Remove the cover for the rear underbody (see Workshop Manual for removing and installing cover for rear underbody).

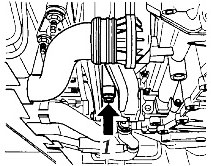

2. Fig. 1, Item 1 shows the screw plug in the oil pump cover.

Attention: Oil will run out (0.25-0.5 liters) when you remove the screw plug/control piston. Place a suitable container underneath to catch the oil.

The contact surface in the oil pump cover can become damaged if an unsuitable tool is used for removing the control piston.

• Damage to the contact surface can cause the control piston to stick.

• This can reduce the oil pressure and damage the engine.

• If the control piston does not come out of the oil pump cover by itself, pull it out carefully using a suitable extraction device.

3. Remove the control piston.

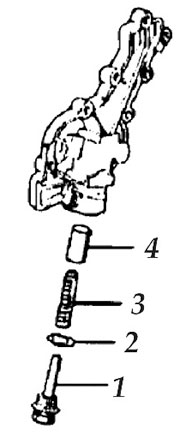

4. Lightly oil the new control piston, P/N 997.107.125.01, and use a new sealing ring, P/N 996.107.123.50 (Fig. 2, Item 2).

5. Install the new control piston, as shown in Fig. 2.

6. Tighten the screw plug.

Note: Tightening torque 37 ft.lbs. (50 Nm), contrary to instructions in the technical manual.

7. Install the cover for the rear underbody (see Workshop Manual for removing and installing cover for rear underbody).

8. Check engine oil level display in the instrument cluster and top up the oil if necessary (see Workshop Manual 770701 – checking engine oil level).

Courtesy of ALLDATA.