File fit ring sets require filing of the top and 2nd rings to achieve the correct end gap. To properly measure the ring gap, the ring should be square in the bore one inch down from the deck.

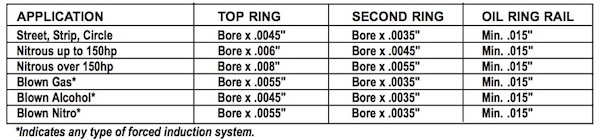

Measure the ring end gap with a feeler gauge or equivalent device. Calculate the recommended ring end gap from the chart (Figure 1).

A proper ring gap filing tool must be used. Ring filing should be done in an inward direction and square to the sides of the ring. Be sure to de-burr all edges after filing.

A proper ring gap filing tool must be used. Ring filing should be done in an inward direction and square to the sides of the ring. Be sure to de-burr all edges after filing.

Correct ring installation is critical. Only Manley rings, top ring has a shiny gray edge. When the top and 2nd ring has a dot, install dot side up. Unmarked top rings with an inner bevel install with bevel up. Unmarked 2nd rings with inner bevel install with bevel down.

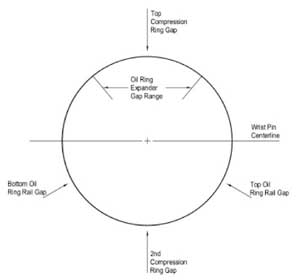

Narrow rings (1.0/1.2mm) that aren’t marked or beveled can be installed with either side up. Do not overlap the ends of the oil ring expander. See orientation diagram (Figure 2).

Ring to piston groove back clearance should be a minimum of .005˝ deeper than the radial wall dimension of the piston ring. The piston ring should not stick out of the groove by any amount. Ring groove side clearance should be a minimum of .0015˝ to a maximum of .0030˝.

Ring to piston groove back clearance should be a minimum of .005˝ deeper than the radial wall dimension of the piston ring. The piston ring should not stick out of the groove by any amount. Ring groove side clearance should be a minimum of .0015˝ to a maximum of .0030˝.

When included, the oil rail supports are installed on the bottom of the oil ring groove underneath the oil rail on Manley rings. The oil rail supports feature a special protruding dimple to prevent rotation of the oil rail support and the protruding dimple should be installed facing the bottom of the piston.

This dimple should be positioned directly in line with the piston pin. Keep the oil rail support gap 90° from the piston pin bore opening.

Tech Tip courtesy of Manley Performance Products.