Applied Vehicles: 2002-’03 Altima (L31) with QR25 and VQ35 engines and Sentra (B15) with QR25 engine; and 2000-’04 Sentra (B15) with QG18 engine.

If you confirm that an applied vehicle has DTCs P0100/P0102/P1102 stored and may also exhibit a rough-running engine, slight engine speed variation while driving or low engine power, then take the following actions:

Actions:

• Remove any dust/dirt/debris from inside the air cleaner housing. This may help prevent another incident.

• Replace the sensor in the airflow meter housing with a new plug-in sensor part (for Altima/Sentra QR25 and VQ35 engines, P/N 22680-8J020; for 2000-’02 Sentra with QG18 engine, P/N 22680-5M020; and for 2003-’04 Sentra with QG18 engine, P/N 22680-8U320).

• Install a new air filter element (P/N 16546-0Z000).

Service Procedure:

1. Remove the ducting from the airflow meter housing.

2. Pull off the connector from the airflow meter.

3. Remove the air cleaner cover with the airflow meter attached.

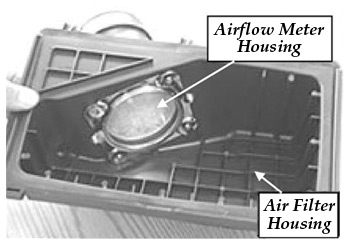

4. Remove the sensor from the airflow meter assembly housing. See Fig. 1. You will do this by removing the two torx screws, which could be either a standard T20 torx or a tamper-resistant torx plus 25IPR. For removal of the 25IPR, you need Essential Tool J47010 Tamper-Resistant Plus 25IPR Bit.

5. Remove the air filter element.

6. Wipe out the inside of the airflow meter housing with a clean shop rag. See Fig. 2.

7. Using low-pressure compressed air or a shop vacuum, clean out all dust/dirt/debris from inside of both halves of the air filter housing, and inside of the airflow meter housing.

Caution: Cover the ducting from the throttle body with a clean shop towel or other method so that no dirt or debris can enter the engine intake manifold. Make sure all dust/dirt/debris is removed from the air filter housing in order to prevent a repeat incident.

8. Install the new plug-in sensor into the old airflow meter housing. Do this by using the two new screws included with the sensor. Hand-tighten using the J47010 bit.

Note: The sensor kit comes with two types of screws. You must put back in the same type of screw that you removed.

9. Install a new replacement air filter element into the filter housing cover.

10. Reassemble the air cleaner housing cover and the intake ducting back to the airflow meter housing.

11. Install the connector back to the airflow meter.

12. Use CONSULT-II to erase any stored DTCs.

13. Verify the MIL stays off.

Courtesy of Mitchell 1.