If you receive customer reports in the model vehicles listed below of the check engine light coming on and codes P2003 (M112, M113, M275), P2047 (M271), P0810 (M272, M273) or P0814 (M272, M273) are stored in the engine control module memory, perform the below procedure.

1. Air Pump Relay

Valid for Models: 164.186, 170.465/466, 171.454/456, 199.376, 203.052/054/056/061/064/065/076/ 081/084/087/092/261/264/281/284/764, 209.356/365/372/375/376/456/465/472/475/476, 211.056/065/070/072/076/082/9083/087/090/256/265/276/282/283/287, 215.373/374/375/376/379, 216.371, 219.372, 220.067/170/173/174/175/176/ 179/183/184, 221.171/186, 230.471/472/474/475/ 476/477/479, 251.156/165

This condition may be caused by a malfunctioning air pump relay. When the secondary air pump relay malfunctions, the air pump may be actuated beyond the maximum permissible operating time. This overload may lead to failure of the secondary air injection pump and result in a malfunction in the secondary air injection system. Proceed as follows:

Note: If diagnosis reveals a malfunctioning air injection pump, refer to step 1.2.

1.1. Test the secondary air injection function chain with SDS.

1.2. If the secondary air pump is determined to be defective, remove/replace the secondary air pump and air pump relay (refer to WIS document: AR14.30-P-7251QB).

1.3. If it’s determined that only the relay is defective, replace only the relay and retest the secondary air injection function chain with SDS.

1.4. Program the engine control module.

2. Check Valve for Vacuum Actuation of Air Pump

Valid for Models: 163.154/157/172/174/175, 164.175/186, 171.454/456/473, 199.376, 203.040/052/ 054/056/0361/064/065/076/081/084/ 087/096/261/264/281/284/740/764, 209.076/356/365/375/376/456/465/475/ 476, 211.056/065/070/076/082/083/087/ 256/265/276/282/283/287, 215.373/374/ 375, 219.375/376, 220.067/170/173/174/ 175/183/184, 230.472/474/475, 463.246/ 249/271

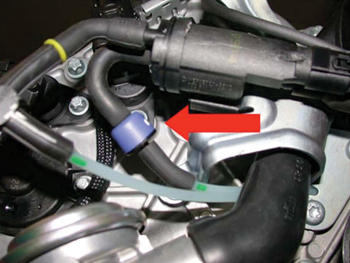

This condition may be caused by a malfunctioning check valve in the vacuum line (see Fig. 1) to the air pump switch-over valve. When the check valve malfunctions, vacuum flow to the diverter valve is restricted, preventing it from opening. Proceed as follows.

2.1. Test the secondary air injection function chain with SDS.

2.2. If the air pump can be activated with SDS but the function chain test fails, the vacuum flow between the air pump switchover valve and the diverter valve may be restricted, preventing the diverter valve from opening.

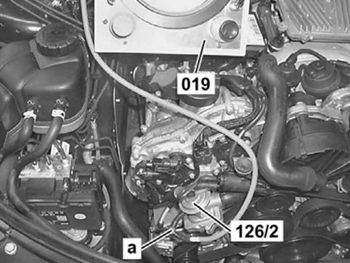

2.3. Check vacuum supply (see Fig. 2) at the diverter valve. If vacuum is < 500 mbar, change the check valve.

Parts Information

Mercedes-Benz Part Name Part Number

Secondary air injection pump Refer to EPC

Check valve A002 140 84 60

Secondary air injection pump relay

(M112, M113, M275, except AMG) (40A) A002 542 72 19

Secondary air injection pump relay

(M271, M272, M273) (70A) A002 542 26 19 28

Secondary air injection pump relay

(M113K, M275LA AMG only) A002 542 66 19

Secondary air injection pump relay

(SLK320 and SLK32 AMG) A170 545 03 05

Secondary air injection pump relay

(C32 AMG and G55 AMG) A002 542 65 19

Note: When ordering a replacement relay, order the part number of the relay being removed. The parts system will deliver the current version of the ordered part.

Courtesy of ALLDATA.