Some customers with 2004-’05 model year RX 330 vehicles may complain of a “ticking” noise from the engine compartment when the engine is idling. Updated fuel main tube and fuel tube clamps are now available. In addition to updated parts, a second fuel pressure pulsation damper assembly has been added to improve this condition.

Repair Procedure:

1. Discharge fuel system pressure.

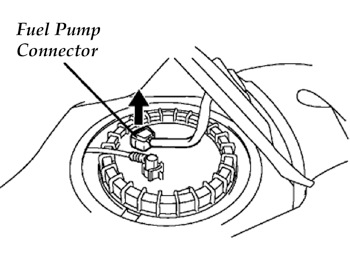

a. Disconnect the fuel pump electrical connector via the access panel under the rear seat. See Fig. 1.

b. Start the engine. After the engine has stalled, turn off the ignition switch.

c. Disconnect the negative (–) battery cable.

d. Reconnect the fuel pump electrical connector and reinstall the rear seat.

2. Disconnect Fuel Pipe Subassembly No. 1.

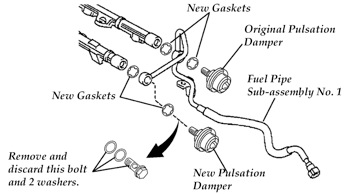

Note: Ensure that the removed bolt and washers are discarded. See Fig. 2.

a. Disconnect the fuel pipe clamp No. 1 from the connector.

b. Check for any dirt or mud on the pipe and around the connector before disconnecting the fuel line. Clean if necessary.

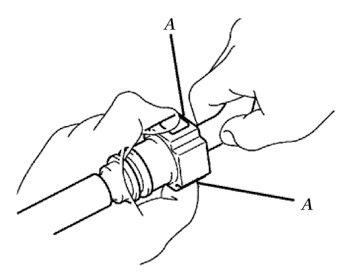

c. Disconnect the connector from the hose while pinching portion “A” with your fingers as shown in Fig. 3.

d. If the connector and pipe are stuck, pinch the fuel pipe and push and pull the connector by hand to disconnect them. Do not use any tools.

e. Drain the fuel that remains inside Fuel Pipe Subassembly No. 1.

f. Protect the disconnected fuel lines from debris by covering with a vinyl or plastic bag.

g. Remove the original pulsation damper from the rear fuel rail. Refer back to Fig. 2.

h. Remove and discard the remaining bolt holding Fuel Pipe Subassembly No. 1 to the front fuel rail.

3. Install the new Fuel Pipe Subassembly No. 1 onto the vehicle.

a. Install both the original pulsation damper and the new (additional) damper with new fuel pipe hose gaskets as shown in Fig. 2, and torque to the following specifications:

Torque: 33 Nm (24 ft.-lbf.)

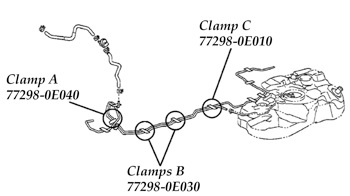

4. Remove and replace fuel tube clamps “B” in Fig. 4 if production clamps do not have rubber insulation like the service parts.

5. Remove and replace fuel tube clamp “A” in Fig. 4 if it’s not a “rigid-style” clamp (without rubber insulation).

6. Clamp “C” in Fig. 4 will not need to be replaced unless it was damaged during the repair.

7. Check for fuel leaks.

a. Reconnect the negative (–) battery terminal.

b. Connect the Lexus Diagnostic Tester or equivalent.

c. Turn the ignition switch to the “On” position (do not start engine).

d. Turn on the tester.

e. Select “1. DIAGNOSIS” on the diagnostic tester.

f. Select “2. ENHANCED OBD II.”

g. Select “3. ACTIVE TEST.”

h. Select “FUEL PUMP/SPD.”

i. Turn on the fuel pump with Active Test by pressing the right arrow on the diagnostic tester.

j. Check for fuel leaks.

k. Check and clear any DTCs that may have been set while performing the repair.

8. Once it has been confirmed that no leaks are present, take the vehicle on a test-drive to ensure any air trapped in the pulsation dampers has been purged.

Courtesy of MotoLOGIC Repair & Diagnostics: www.motoshop.com/motologic.