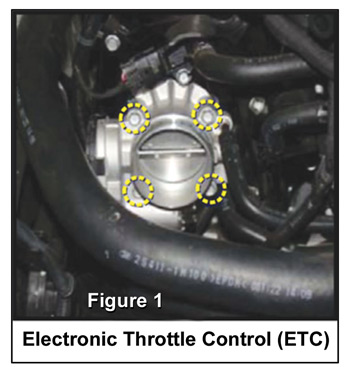

Dirty throttle bodies can cause a variety of concerns and may result in MIL illumination (see Fig. 1). Although the ECU may compensate for changes in air flow with fuel trim adaptive logic adjustments, DTCs may illuminate over time. The ETC assembly should not be replaced for contamination. Any deposits need to be cleaned off following the instruction in this Tech Tip.

Applicable Models: Kia Rondo, Forte, Optima, Sorento with Theta 2.0/2.4L engine.

Repair Procedure:

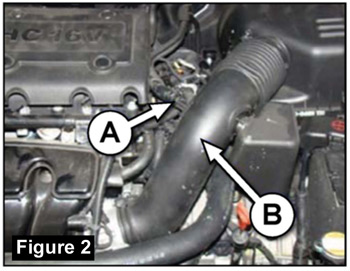

1. Remove the breather hose (A) and the air intake hose (B), to gain access to the ETC assembly (see Fig. 2).

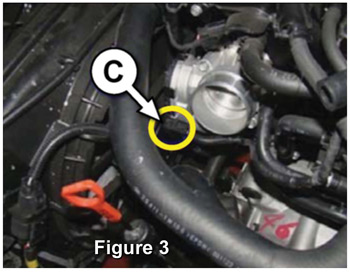

2. Disconnect the ETC connector (C) (see Fig. 3).

Caution: Keep hands away from the throttle body unless the connector is disconnected.

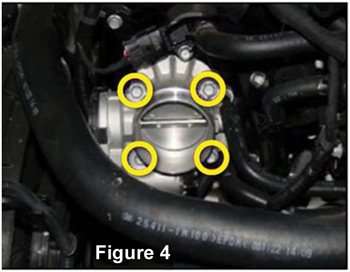

3. Remove the four ETC mounting bolts as indicated and the ETC from the intake manifold (see

Fig. 4).

Caution: It’s not necessary to completely disconnect the coolant hose from the ETC for this particular repair.

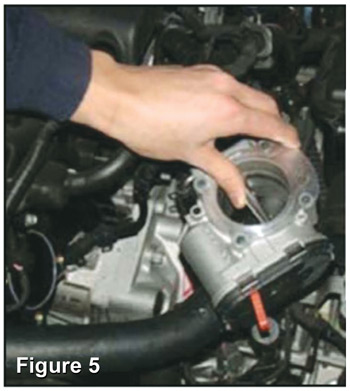

4. Spray throttle plate cleaner onto the throttle valve and bore areas and wipe off the carbon deposits with a rag or shop towel (see Figs. 5 and 6).

Caution: Be careful while trying to open throttle plate and avoid making any scratches to the throttle valve and bore areas during cleaning.

5. After the ETC cleaning procedure is complete; reinstall all the removed parts in reverse order of removal.

Tightening torque for ETC mounting bolts:

Theta I 2.4L: 5.8-7.2 ft.-lbs. (7.8-9.8 Nm)

Theta II 2.0L/2.4L: 7.2-8.7 ft.-lbs. (9.8-11.8 Nm)

Notice: If the ETC gasket has been damaged or contaminated by foreign substances, be sure to replace it with a new one.

6. Erase all the DTCs in the engine system with the use of GDS (Global Diagnostic System).

7. Reset the learned ETC Throttle Valve Position in the engine system with use of GDS by going to “System Option.”

8. Turn the ignition key to the On position for two seconds and Off for five seconds (do not start the engine) to allow the ECM to automatically perform the throttle valve position learning operation.

Notice: The following parameters should be met for proper throttle position relearning: Battery > 10V and Engine Coolant Temperature > 41.5° F (5.3° C).

9. Drive the vehicle to confirm the repair.

By Chris Burton, ALLDATA editor and Jeff Webster, ALLDATA technical writer.