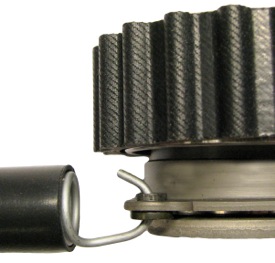

When installing a GTKWP312 kit on a 2001-’05 Civic 1.7L, it’s crucial that the tensioner spring be installed correctly onto the tensioner. If it’s improperly installed, the open end of the spring hook can catch on the timing belt, possibly leading to severe engine damage.

The open end of the spring hook must be installed on the tensioner so that it is facing away from the belt and toward the engine block. The OE spring, which is included in the kit, should be replaced along with the other timing components. Use of the old spring will void the kit warranty.

Remember, it’s important to replace all of the components included in the timing belt kit to validate the manufacturer’s warranty.

Courtesy of Veyance Technologies.