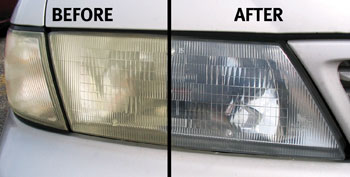

Today, plastic headlamp lenses are a way of life for almost all vehicles. Over time, these lenses can haze over from the effects of sunlight, pollution, car wash chemicals and road grit, blocking light output and reducing nighttime driving visibility.

You can easily solve this safety problem for your customers, save them hundreds of dollars on headlight replacements, and bring in some extra service dollars to your shop at the same time.

A new Headlight Lens Restoration Kit from Permatex lets techs restore a cloudy, yellowed or scratched plastic headlight lens to “like new” clarity in less than 45 minutes without special tools or training. The kit has everything needed to bring two dull headlamps back to life, including various grades of sand paper, plastic polish, polishing cloth, protective gloves and instructions. There’s even a short demo video online at: www.permatex.com/trainingvideos.htm that can walk techs through the process.

Easy Step-by-Step Repair

1. Clean the headlight lens — This will remove any dirt, grease or abrasives. Dry thoroughly.

2. Mask the area around the lens — This will help protect paint, trim and chrome surfaces. A low tack tape works best and won’t damage the paint.

3. Evaluate the damage — This will help you determine which grit sandpaper you need and how much sanding and polishing will be required. A lightly clouded lens with no scratches could be restored with just the polishing compound.

4. Sand the lens surface — The kit comes with four grades of sandpaper from coarse grit 1,000 to fine 2,500. Start with the 1,000 grit and soak it in water for 10 minutes. Sand the entire lens using a straight back-and-forth motion in the same direction. (See Figure 1). Keep the sandpaper and lens wet at all times. This will keep it lubricated and free of abraded particles. Sand for about 8-10 minutes.

When the surface of the headlight lens begins to look uniform, use the next higher number sandpaper and sand in the opposite direction (left to right vs. up and down). Sand for approximately 3-5 minutes or until the sanding lines from the previous sandpaper have been removed.

Repeat this step for all of the remaining grades. After using the 2,500-grit sandpaper, the surface of the plastic lens should appear uniform, but not completely clear.

5. Clean the headlight lens — Use clean water to remove sanding particles and dry thoroughly. (See Figure 2).

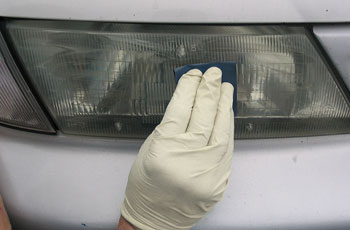

6. Polish the lens surface — Apply plastic polish to one corner of the polishing cloth and start buffing the lens in a circular pattern, using firm pressure. Polish the lens until it becomes very smooth and clear. Allow polish to dry on the lens. Remove the residue using the dry end of the polishing cloth. (See Figure 3).

Note: If headlight lens is not completely clear, repeat cleaning and polishing steps as needed until clarity is achieved.

Helpful Hints

1. Keep the plastic surface and sandpaper completely wet to prevent clogging.

2. Change the soaking water with each sandpaper grade to remove sanding particles.

3. Shake Plastic Polish thoroughly before use. Apply firm pressure while buffing.

Caution: This repair is intended only for the outside lens surface. Headlights with internal damage should be replaced.

Note: While this “how-to” Tech Tip was submitted by Permatex, there are other headlight lens restoration kits available from aftermarket suppliers. Underhood Service does not endorse any one headlamp lens product. It is up to your shop to research and determine which system works best for you.

Did You Know…

According to 3M, millions of drivers are on the road today with a safety problem they may never see — hazed or cloudy plastic headlights that reduce visibility and make it very difficult to see obstacles and other vehicles.

These hazed headlights also give the vehicle an aged, unsightly appearance and decrease its value.

While plastic headlights help reduce vehicle weight and withstand impact, oxidation and sunlight can dull the surface, turn it yellow or leave it cloudy and hazy. This means the light from the headlights is diffused and not focused correctly on the roadway, which limits visibility in dark, rainy or foggy conditions. Not only can the driver of the vehicle not see the roadway, the vehicle also is less visible to other cars.

With the average age of vehicles on U.S. streets today nearing nine years, the safety problem is growing. According to 3M, cloudy headlights are a common problem with 1990s Ford Taurus (top photo) and late-model Jeep Cherokee vehicles.

Designed to meet the needs of professional shops, the Headlight Lens Restoration System from 3M helps increase productivity by significantly reducing the amount of time it takes to restore headlights to like-new illumination. One headlight can be restored in as little as 12 minutes, compared to traditional manual methods that can take up to 40 minutes per headlight.