MODELS:

• 2006-2009 Fusion

• 2007 Zephyr

• 2007-2009 MKZ

• 2006-2009 Milan

ISSUE:

Some vehicles built before 8/5/2008 may exhibit a popping, rubbing, grunting, squeaking, crunching or creaking type noise from the front strut mount when going over bumps, while driving at 1-10 MPH and/or during parking lot maneuvers. Typically, the noise is heard in the front outboard wheel while turning at low speeds. This noise may be caused by the jounce bumper rubbing against the dry strut plate.

ACTION:

Follow the Service Procedure steps to correct the condition.

SERVICE PROCEDURE:

1. Raise the vehicle.

2. Remove front shock absorber and spring assembly.

3. Disassemble the shock absorber and spring assembly.

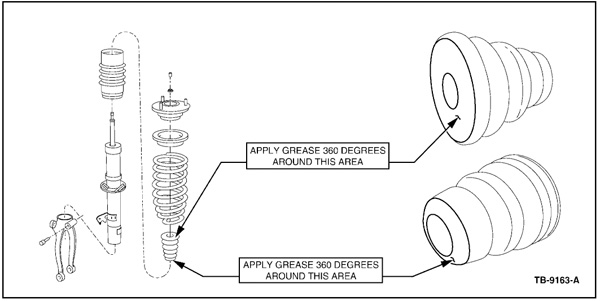

4. Apply silicone brake caliper grease and dielectric compound around the upper and lower contact surfaces of the shock absorber piston bounce bumper.

5. Repeat the procedure on the other side of the vehicle.

6. Lower the vehicle.

Courtesy of Mitchell 1.

Wheel Bearing Shortcuts

When you’re installing a wheel speed sensor on a hub unit, never ever remove it from the original unit. Sponsored by Auto Value and Bumper to Bumper.

Hey, I got a great shortcut for you. If you're working on wheel hubs, if you have one where you're dealing with a harness for the wheel speed sensor that may be behind a fender liner, has all these horrible Christmas trees on it to get in and out from behind areas that you've never seen, well, you can just simply take the old out and then put it in the new and get rid of the new harness. Do not ever use the shortcut. It is a bad thing to do because you are destroying the calibrated air gap that was done at the factory, and this is very precise, done with computers. By removing the wheel speed sensor from one and putting it in another, you've just changed everything completely and you're gonna cause yourself a comeback. Do you wanna know why? Well, it's gonna cause an erratic wheel speed sensor code or issues with the air gap.

Monitor Water Quality When Servicing Coolant

The harder the water, the more likely the water pump is to develop a leak.

Rough Running GM Vehicle

This condition may be caused by an internal circuit board fault within the throttle body.

Diagnosing Intercooler Boost Trouble Code P0299

The criteria for setting the code is very basic.

Autel Energy Europe Releases MaxiCharger Launch Plan

Autel introduced the MaxiCharger Megawatt Charging System satellite launch plan at the Nordic EV Summit 2024.

Other Posts

Success Means Investing In More Than Equipment

Todd Baldridge measures success by how well his team benefits from being together.

Fenix Parts Completes Acquisition of Neal Auto Parts

Neal is an automotive recycler servicing the Central Illinois market with a population of approximately 1.3 million people.

Clarios to Supply High-Performance AGM Battery to Major OEM

It offers up to 80% reduction in CO2 emissions over traditional AGM batteries, in many cases, Clarios said.

FLO, GM Activate Plug and Charge for GM EV Drivers in Canada

FLO’s technology confirms identification, authorizes the charging session and activates billing without any additional action from the driver.