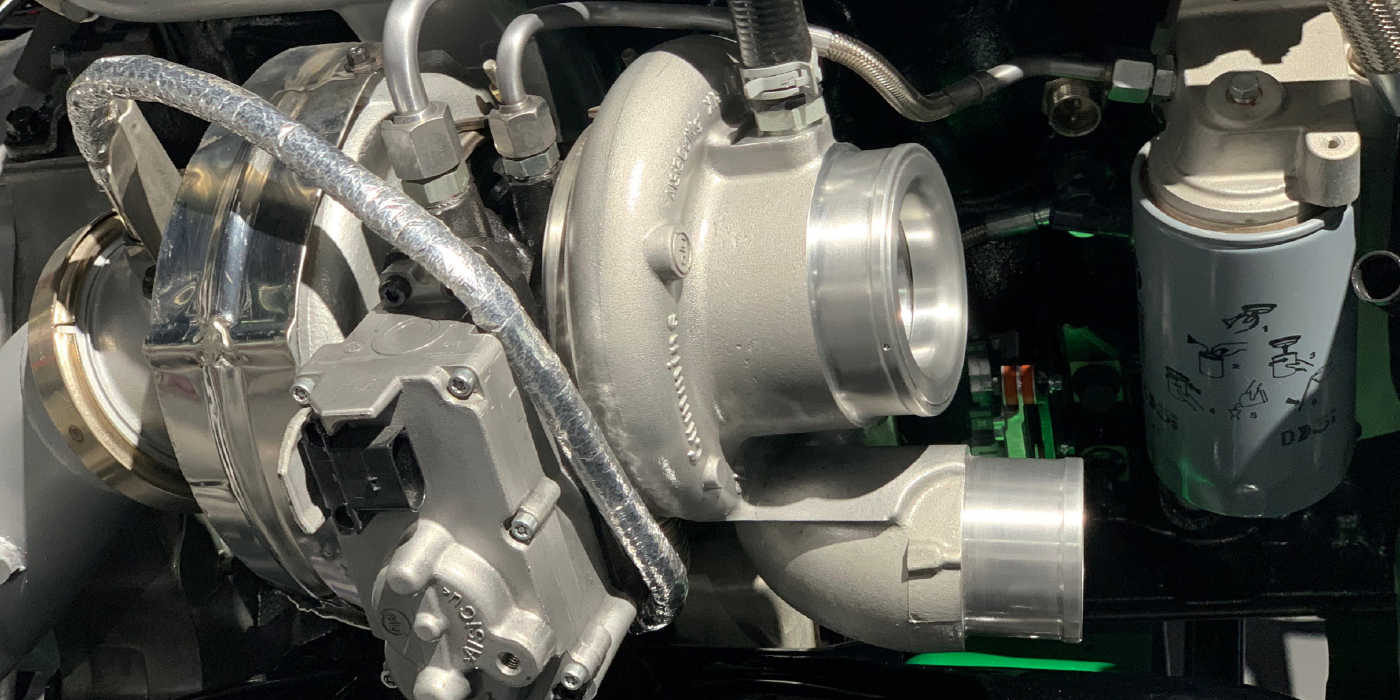

Application: 2003-’09 Chrysler PT Cruiser and Dodge Neon with turbochargers; 2T-315.

Problem: Premature turbocharger failure.

Cause: Extreme temperatures cause the oil circulating through the turbocharger oil feed line to burn. The coked oil buildup restricts oil flow, which leads to turbocharger failure. The oil line may appear fine externally.

Solution: The oil feed line must be replaced as well as the turbocharger. Look for a turbocharger that includes a new, upgraded oil feed line with heat shield, so you don’t have to source it separately. Installing this new line will restore oil flow and ensure the longest possible service life of the replacement turbocharger.

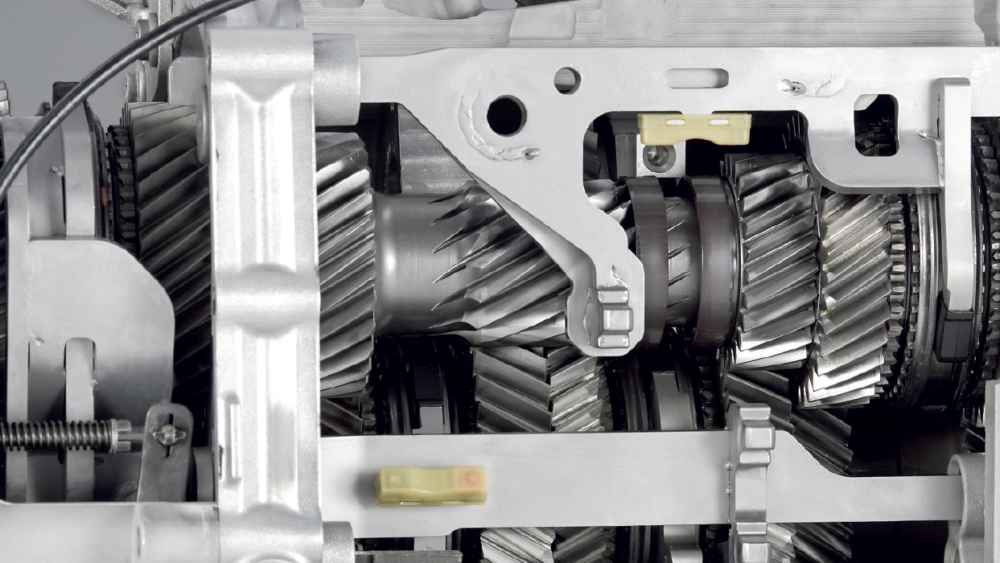

BMW Dual-Clutch Transmission Diagnostics

A DCT transmission uses the gearing principles of a manual transmission.

The phrase “dual-clutch transmission” or DCT can strike terror in the heart of some BMW engineers and technicians. You will probably never deal with the internals of a DCT transmission like the gears, synchronizers and shafts. You will instead have to repair the external components that control the clutches and cool the fluid. But, understanding how the gears and shafts work together is essential.

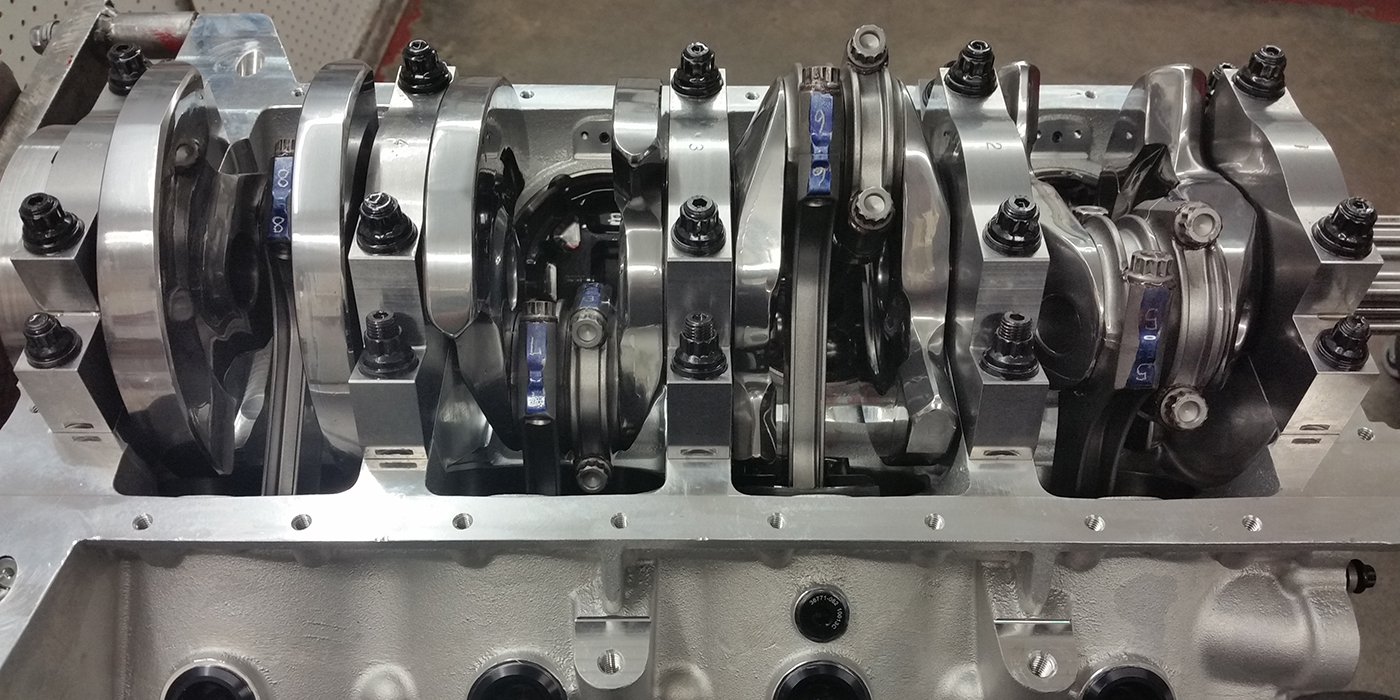

Simple Engine Fasteners Actually Complex Engineering Systems

Fasteners act much the same as a spring due to the physics of stretch and rebound.

Superchargers: Pros And Cons

Customers generally look to superchargers for the instant throttle response, not fuel economy.

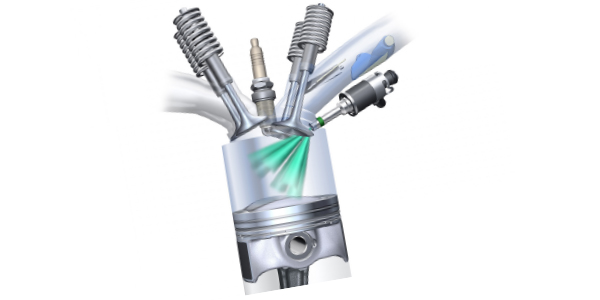

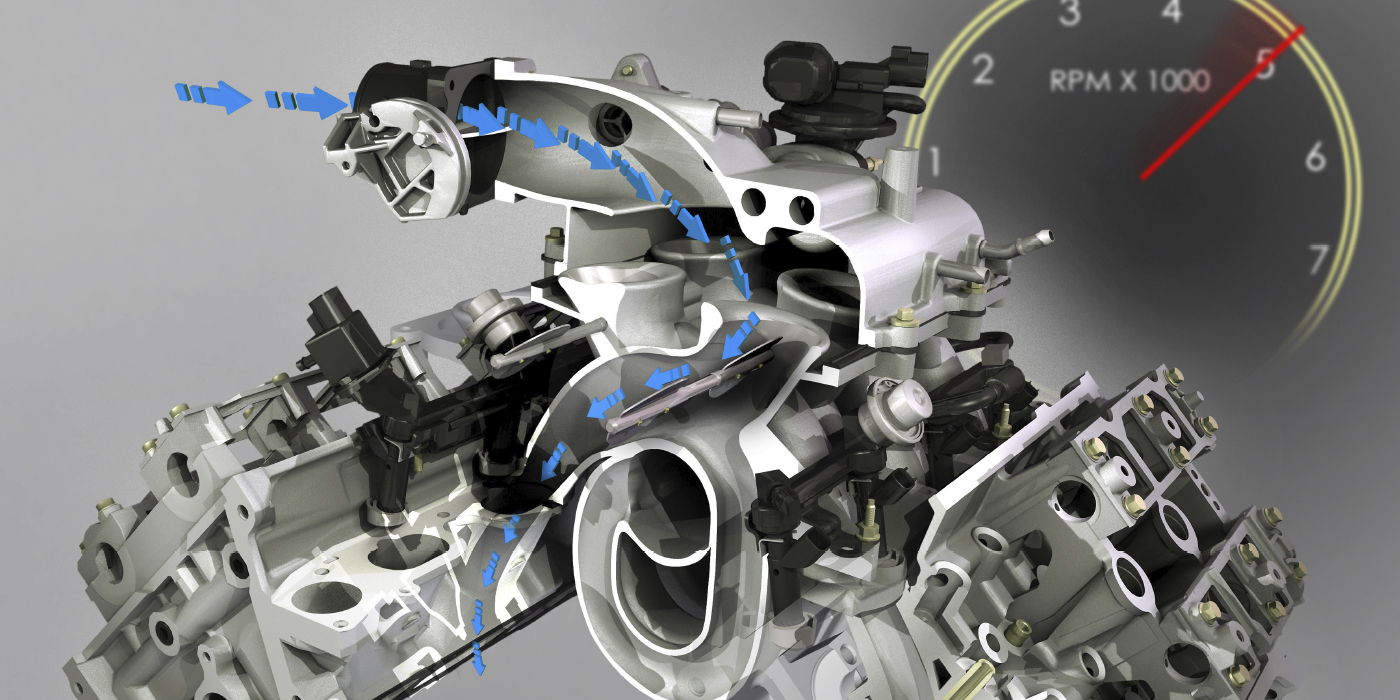

Runners And Ports: How Modern Engines Manage Air

Variable-length intake runners change the length of the intake passages depending on engine speed and load.

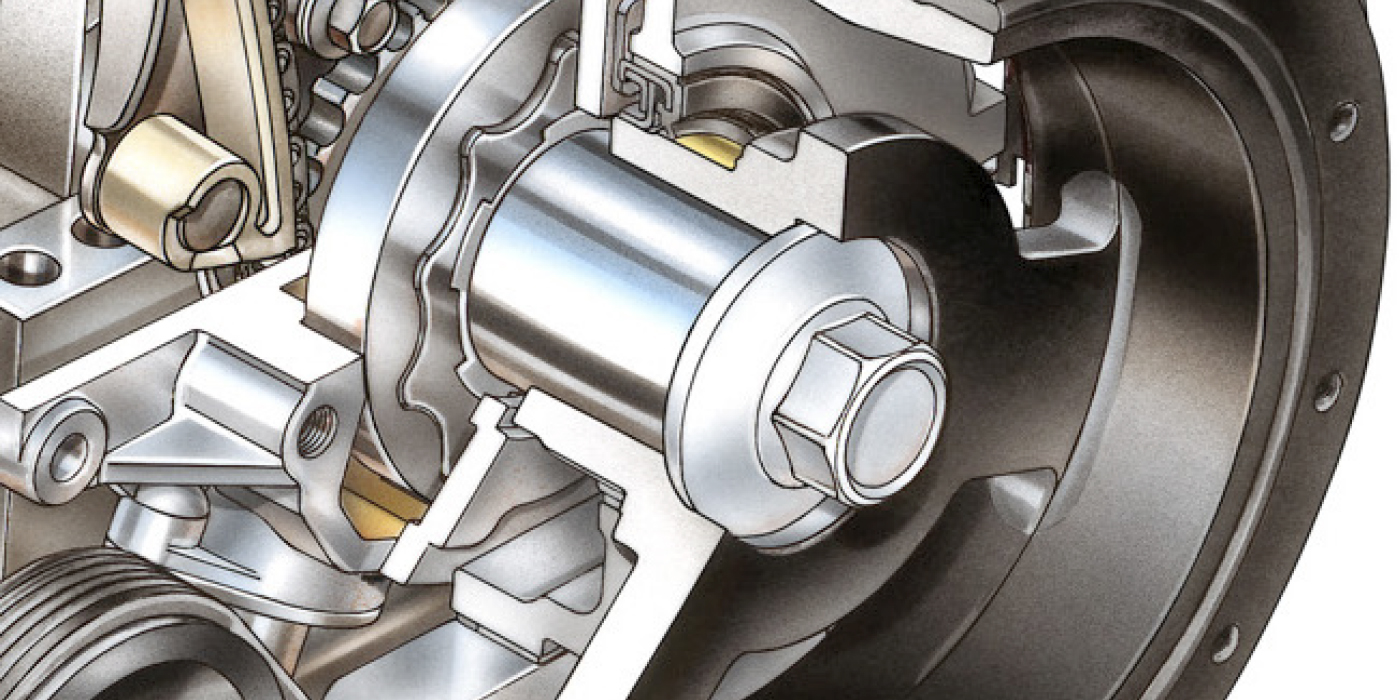

Driveshaft Universal Joint Tips And Techniques

Before removing the driveshaft, check for play in the yoke and slip joint. If the u-joints are failing, you should be able to see movement in the shaft as you apply leverage.

Other Posts

Diesel Air Filter Replacement

Here are some diesel air filter replacement tips in order to keep these vehicles running as intended.

Diesel Turbocharging Basics

There’s a reason diesels typically utilize compound turbo setups instead of twin turbochargers.

Best Practices for Turbo Services (VIDEO)

Turbo performance can only be impaired by mechanical damage or debris. Sponsored by Standard Motor Products.

Verifying Boost Pressure Diagnostics

Boost pressure is determined by the speed of the exhaust turbine.