Models 1987-’92 (MJ) Comanche, (XJ) Cherokee, (YJ) Wrangler; 1993 (ZJ) Grand Cherokee

Some vehicles equipped with a 4.0L engine, may experience engine oil leaks/seepage from the head gasket along the right-hand side (tappet rail) of the engine.

A new cylinder head gasket is now available. The new gasket has beaded silicone sealer on both sides to eliminate leakage/seepage.

Diagnosis

Diagnosis

Verify the oil leak/seepage is coming from the cylinder head gasket by visual inspection, or using fluorescent dye or by doing a low pressure leak test.

Repair Procedure

This repair involves replacement of the cylinder head gasket with a revised gasket using instructions outlined in the appropriate service manual using cylinder head gasket P/N 53020219 or equivalent.

Coat a new head gasket with suitable sealing compound and place it on the block. Most replacement gaskets will have the word TOP stamped on them.

Note: Apply sealing compound only to the cylinder head gasket. Do not allow sealing compound to enter the cylinder bore. The 1991-’98 cylinder head gaskets used on the 4.0L are a composition gasket. This gasket should be installed dry.

Do not use sealing compound.

Install the cylinder head and bolts. The threads of bolt No. 11 must be coated with Loctite 592 sealant before installation.

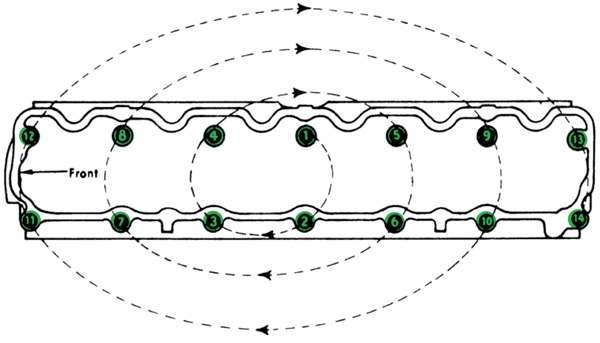

Tighten the bolts in three steps, using the correct sequence (see Figure 1):

1. Tighten all bolts to 22 ft.-lbs. (30 Nm).

2. Tighten all bolts to 45 ft.-lbs. (61 Nm).

3. Retighten all bolts to 45 ft.-lbs. (61 Nm).

4. Tighten bolts 1 through 10 in sequence to 110 ft.-lbs. (150 Nm).

5. Tighten bolt 11 to 100 ft.-lbs. (136 Nm)

6. Tighten bolts 12 through 14 to 110 ft.-lbs. (150 Nm)

Note: Cylinder head bolts should be reused only once. Replace the head bolts that were previously used or are marked with paint. If head bolts are to be reused, mark each head bolt with paint for future reference. Head bolts should be installed using sealer.

Some or all of this information was provided by the Automotive Parts Remanufacturers Association (APRA). For more information on technical bulletins available through APRA, call 703-968-2772 or visit www.AutoBulletins.com.