By Larry Carley

Technical Editor

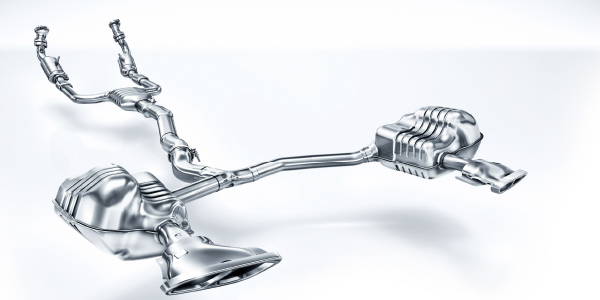

The catalytic converter is probably the most important emission control device on a vehicle because it cleans up the pollutants in the exhaust. Thanks to fuel injection, oxygen sensors in the exhaust manifolds, and a feedback fuel control system, emissions are kept to a minimum. Even so, some pollution is still produced and must be eliminated by the converter. So the converter must be in good condition and working correctly to keep tailpipe emissions to an absolute minimum. And if there’s a problem? Then your customer’s vehicle will probably need a new converter.

Converter problems typically fall into one of five categories:

1. Plugged converter (partially or completely);

2. Dead converter;

3. Marginal converter (still working, but efficiency is down);

4. Damaged converter (rust or physical damage); or

5. Missing converter (somebody stole it!).

PLUGGED CONVERTER

PLUGGED CONVERTER

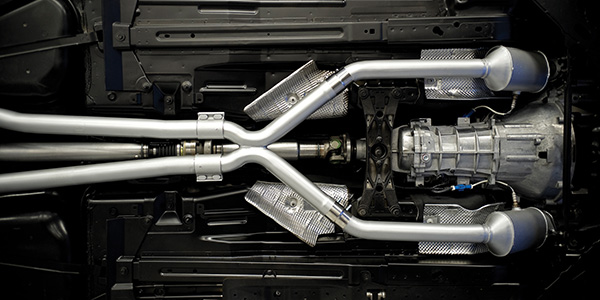

A partially plugged converter will create a restriction in the exhaust system. This, in turn, will cause an increase in exhaust backpressure that can strangle engine performance, particularly at highway speeds. The engine may start and idle normally, but lack high speed power. Fuel economy may also be down.

At first, you may suspect low fuel pressure or a plugged fuel filter (which can cause similar symptoms). A simple fuel pressure check with a gauge will tell you if idle pressure is within specifications, and a flow test will tell you if the fuel pump is capable of delivering enough fuel volume to meet the engine’s demands. You may also replace the fuel filter in an effort to cure your customer’s problem. But when the problem persists, it’s obviously not fuel-related. More likely, it’s an exhaust restriction.

An exhaust restriction created by a partially plugged converter can also backup heat in the engine, causing the engine to run hot and possibly overheat. If this is the case, you may suspect a cooling system problem. A low coolant level, coolant leak (internal or external), stuck thermostat, defective cooling fan, clogged radiator, kinked radiator hose or bad water pump can all make an engine run hot and overheat. So if you’ve checked all of these things and found no problem, you may be scratching your head wondering what’s going on?

The fact is, many technicians don’t consider the converter as a possible cause of engine performance problems or overheating until they’ve exhausted all the other possibilities. So maybe a better diagnostic approach would be to check the converter first when an engine is exhibiting symptoms that may be due to a converter restriction.

One of the quickest and easiest tests to perform is to check intake vacuum with a vacuum gauge. Find a place to connect a vacuum gauge to the intake manifold, and start the engine. Intake vacuum should usually be 18 to 22 inches of mercury (Hg) and remain steady at idle. If the vacuum reading is low and continues to drop, the converter may be causing a restriction.

Next, increase engine speed to 2,500 rpm and hold steady. The vacuum gauge needle will drop when you first open the throttle, then stabilize. But if the vacuum reading remains low or continues to drop, backpressure is building up in the exhaust system.

Disconnect the converter and recheck the intake vacuum reading. If the reading goes back to normal, you’ve identified an exhaust restriction that needs further diagnosis before you condemn the converter. Though a plugged converter would be the most likely cause of the restriction, it’s also possible the exhaust system may have a collapsed or pinched exhaust pipe, or the muffler may be clogged.

An alternative to measuring intake vacuum is to measure exhaust backpressure. It’s a much more difficult check to make because you have to find a place in the exhaust system to attach a gauge. If the engine has air injection, you can disconnect the check valve from the distribution manifold to hook up a gauge. Or, if you really want to make a lot of extra work for yourself, you can remove the oxygen sensor and take your reading at its hole in the manifold or headpipe. Refer to the backpressure specs for the application. Generally speaking, more than 1 psi of backpressure at idle, or more than 4 psi of backpressure with snap acceleration of the throttle is too much and indicates an exhaust restriction.

If the converter is completely plugged, it should be a no-brainer to diagnose. The engine will start, run for maybe a minute or so, then stall as exhaust backpressure builds up and strangles the flow of exhaust out of the engine.

If you suspect the converter is plugged, disconnect the converter and hold a trouble light up to one end. Then look in the other end. If you can’t see through the honeycomb, the converter is obstructed and needs to be replaced.

But before you replace the converter, keep in mind the possible reasons for it failing in the first place. Converter restrictions are often caused by severe overheating that damages the honeycomb. The underlying cause may be an overly rich fuel mixture or engine misfire (bad spark plug, plug wire or leaky exhaust valve). Any such problems should be diagnosed and repaired before you replace the converter, otherwise the new unit may suffer the same fate.

DEAD OR MARGINAL CONVERTER

Late model converters are engineered to go well beyond 100,000 miles of normal driving. On many cars and trucks, the converter may go the distance and outlast the vehicle itself. But sometimes converters can be contaminated and die a premature death.

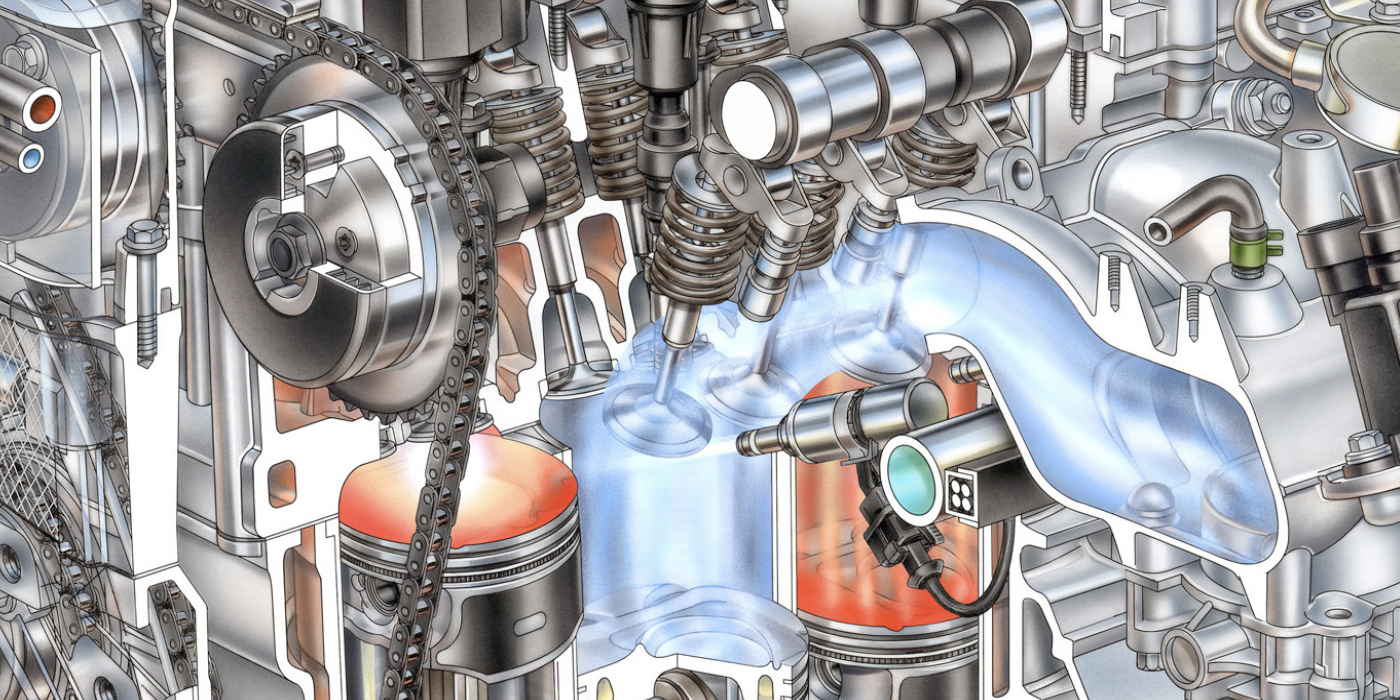

Converters can be fouled by contaminants such as lead from leaded gasoline, phosphorus and zinc from burning oil, or silicone (from coolant that gets into a combustion chamber through a leaky head gasket or cracked cylinder head, or from using the wrong type of RTV silicone sealer as an engine sealer). Newer motor oils have reduced levels of phosphates and zinc to prolong the life of the converter. Long-life OAT-based “orange” coolants, such as Dex-Cool, have also eliminated silicate corrosion inhibitors for the same reason (though silicates are still used in many other OAT-based coolants).

If the platinum, palladium and rhodium catalysts inside the converter become coated with any of these other elements, it can prevent them from triggering the chemical reactions that are necessary to clean up the exhaust. The efficiency of the catalyst drops way down or ceases altogether, causing an increase in emissions out the tailpipe. Since there is no way to rejuvenate a contaminated converter, replacement is the only repair option.

How can you tell if a converter has stopped working? Unless it is plugged and causing a restriction, there are no obvious symptoms a driver would notice. Fuel economy and engine performance are unaffected. The only way to tell is to use an exhaust analyzer to check the gases coming out the tailpipe — and that only happens if the vehicle is required to take an emissions test.

A dead converter will typically cause higher than normal hydrocarbon (HC) and carbon monoxide (CO) readings, which may cause the vehicle to fail the emissions test if these pollutants are above the legal limits.

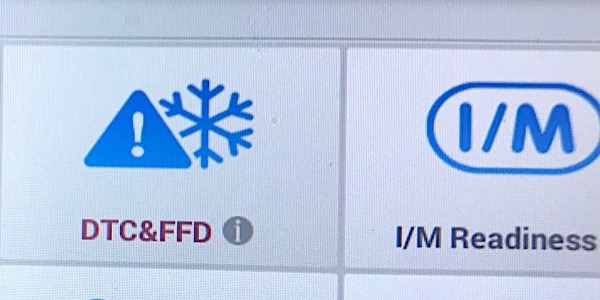

The most obvious indicator of a bad converter (and usually the most accurate), however, is a Check Engine Light accompanied by a converter-related code, such as P0420 or P0430.

Since 1996, vehicles equipped with Onboard Diagnostic II (OBD II) have incorporated a “catalyst monitor” to keep an eye on how efficiently the converter is working. The catalyst monitor compares the signal from a “downstream” O2 sensor in or behind the converter to that from the upstream O2 sensor(s). The O2 sensors react to oxygen levels in the exhaust. If the converter is working at high efficiency, the downstream O2 sensor signal will be almost flat and show very little switching activity compared to the upstream O2 sensor(s). But if the converter is contaminated and is doing little or nothing to clean up the exhaust, the activity of the downstream O2 sensor will mirror that of the upstream O2 sensor(s).

The threshold at which the OBD II system will set a catalyst fault code will vary according to the year, make and model of the vehicle, and the emission levels to which that vehicle was originally certified. But as a rule, a drop in catalyst efficiency of 10% or more will usually set a fault code and turn on the Check Engine Light.

Since a vehicle can’t pass a plug-in OBD II emissions test with an illuminated Check Engine Light, you can take one of two courses of action: you can replace the converter now, or you can clear the code, tell your customer to drive the vehicle for a few days to see if the light comes back on (which it likely will), and then replace the converter when he comes back the second time.

The catalyst monitor can take awhile to set, and typically requires driving the vehicle at various speeds including 15 to 20 minutes of highway driving. It may take several days before the monitor runs and sets a code, but sooner or later it will set a code if the converter is bad.

But there is an exception. If the vehicle has a bad upstream or downstream O2 sensor, and the OBD II system has detected it and set a code, it will prevent the catalyst monitor from running. The oxygen sensor problem, therefore, must be fixed before you can verify whether or not the converter is working properly.

Converter efficiency can also be checked with an infrared exhaust analyzer. But many shops don’t have an exhaust analyzer, and chances are if the OBD II system says the converter is not working up to par, it probably is not.

You can also look at the reaction of the upstream and downstream O2 sensors on a digital storage oscilloscope to make sure the O2 sensors are working normally. But as long as there are no O2 sensor issues and the system is setting a catalyst code, you have to assume the catalyst is contaminated and is not working at normal efficiency. Remember, the converter first has to pass the OBD II catalyst monitor self-test before it can be allowed to take a plug-in OBD II emissions test. If the catalyst monitor won’t run, or the converter fails the test, the car won’t pass.

CHECK ENGINE LIGHT BACK ON AGAIN

So what happens if you replace the converter, the catalyst monitor runs and resets the same code again? Now you have a real problem. It’s unlikely a new replacement converter would be defective out of the box. But we have heard of instances of “reconditioned” converters not performing as advertised.

Assuming you replaced the old converter with a brand new one, a low converter efficiency fault code that reappears would most likely be due to a lazy upstream O2 sensor.

When the front O2 sensor is slow to respond to changes in the air/fuel mixture, the fuel feedback control loop may not be changing the fuel mixture back and forth from rich to lean often enough to provide enough extra oxygen in the exhaust for the converter to burn up all of the pollutants. This causes a drop in converter efficiency, which the OBD II system blames on the converter.

The fix, of course, is not to replace the converter a second time, but to replace the lazy upstream O2 sensor(s). The hard part is explaining all of this to your customer who just paid you several hundred dollars for a new converter he didn’t really need!

CONVERTER DAMAGE

Another reason for replacing a converter is if the shell has rusted through and blown out, or the converter has been physically damaged by running over something.

The converter is surrounded by a heat shield that keeps heat away from the underside of the car. Over time, rust and vibration may crack the heat shield causing it to come loose or fall off. Loose heat shields are a common cause of exhaust rattle and noise. The shield can often be repaired or replaced. But if the converter shell has rusted though, the whole converter must be replaced.

The catalytic converter is covered by an OEM 8-year, 80,000-mile emissions warranty. California vehicles have a 10-year, 100,000-mile warranty, and California vehicles with a “PZEV” classification have a 150,000 mile OEM converter warranty. If a converter needs to be replaced during the covered warranty period, the need to do so must be confirmed and documented by an emissions test failure. A new car dealer should replace the converter at no cost if it is still under warranty.

MISSING CONVERTER

A new kind of converter problem that has emerged recently in response to soaring metal prices is the vanishing converter. The motorist starts his car or truck in the morning and is greeted with a loud exhaust roar. When he peers underneath, he sees his exhaust pipes have been sawed off and his converter has disappeared. Vehicles most vulnerable to this kind of theft are those with a lot of ground clearance like four-wheel drive pickup trucks and SUVs.

Thieves are stealing converters because scrap dealers are paying $50 to $100 or more for the platinum, palladium and rhodium catalysts inside the converter. To counter this kind of theft, a growing number of states are now requiring scrap dealers to take down names and driver license numbers of persons selling used converters.

If a converter has been stolen, it must be replaced with another converter (same type and same location as the original). It is illegal to replace a missing converter with a straight pipe.