Bartec USA Announces New TPMS Sensor

RITE-SENSOR is Bartec’s programmable, single part, multi-frequency, replacement TPMS Sensor.

Selling TPMS At The Front Counter

Every time a tire is removed from a car, the TPMS should get a new service kit. Not replacing the kits could cause big problems with tire pressure and vehicle TPMS if not properly serviced.

TPMS Service Opportunities: The 656-Million Sensor Market

September 2018 marked the 11-year anniversary of mandatory tire pressure monitoring systems (TPMS) for all light vehicles sold in the U.S. During these past 11 years, more than 164 million vehicles have been equipped with TPMS. If you multiply that number by four, it means that there are more than 656 million tire pressure sensors that will need replacement at some point.

TPMS Service: 2011 Toyota RAV4

TPMS relearns for the 2011 Toyota RAV4 are fairly straightforward and simple. The RAV4 doesn’t have a reset button underneath the dash or within the glove box, meaning technicians don’t have to worry about getting a TPMS relearn malfunction due to the vehicle’s ECU closed loop. This also means that in order to successfully service the RAV4’s TPMS, a shop needs a dedicated TPMS scan tool.

TPMS And Radio Waves: What You Can’t See Can Hold Up A Relearn

TPMS and keyless entry can be difficult to understand because these systems rely on transmitting, receiving and decoding radio waves. You can see wires connecting modules and components, but seeing radio signals takes a little faith in science.

Getting The TPMS Light Out On The First Try

Whether the customer brings in the vehicle with a TPMS light triggered, or one triggers as a result of performing some tire service, not being able to turn off the MIL can sometimes cause headaches for shops. Here are a few commonly overlooked issues that could be triggering a warning light.

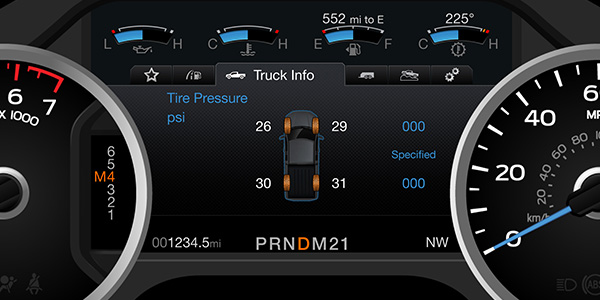

Ford TPMS Service

Ford embraced tire pressure monitoring systems (TPMS) as early as the 2002 model year on the Explorer and Windstar. These systems can be either direct or indirect. From 2006-’09, Ford used banded sensors mounted in the center of the rim. In 2010, Ford reverted to valve stem-mounted sensors. All the systems are straightforward and common service procedures apply to most models.

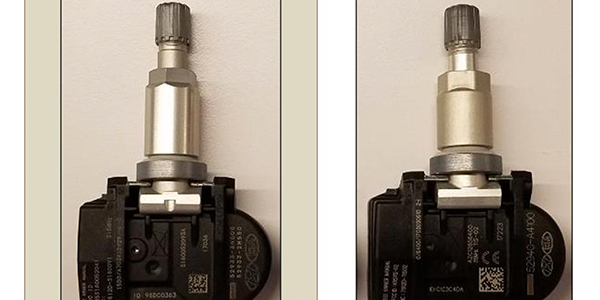

Understanding Hyundai TPMS

Hyundai TPMS has an auto relearn function, but if a shop is initializing a sensor or doing a manual relearn, you will need a TPMS tool that can capture the sensor IDs and program them into the TPMS module.

Subaru TPMS: Better Service These Direct Systems With Dedicated TPMS Tools

Subaru first started experimenting with TPMS in its vehicles in 2004 with the Subaru Outback and Subaru Legacy. The Subaru B9 Tribeca was outfitted with TPMS in 2006 and the automaker added TPMS to all of its other models in 2008. The TPMS on Subarus are direct systems. In order to properly service and reset these systems, it’s important that a shop invests in a TPMS tool that can interface through the OBDII port.

Selling Four TPMS Sensors

If a single sensor has reached the end of its lifespan, it is highly recommended to replace all sensors at the same time. Similar to headlights, once one sensor dies, the rest are likely to be close behind. This is an important point for your customers to understand. Taking care of the issue before there is a problem also provides a convenience to them.

TPMS Service Kits: The Key To TPMS Maintenance

Anytime a tire is removed from the rim of a vehicle, a new TPMS kit must be installed. The existing sensor kit could be brand new or years old, but every tire removal should include the replacement of the TPMS sensor kit. Not replacing the kits could cause big problems with tire pressure and the vehicle’s TPMS if not properly serviced.

Corrosion And TPMS

It is that time of year again when the affects of road salt, deicers and potholes start to take their toll on vehicles. The latest victims of the salt belt are TPMS sensors and valve stems. The corrosion we are all most familiar with is that which affects steel, iron’s most common alloy. While just the presence of oxygen in the air, along with some moisture, is enough for something made of steel to begin to corrode, most of the time it is accelerated by some other environmental factor, which causes the most problems.