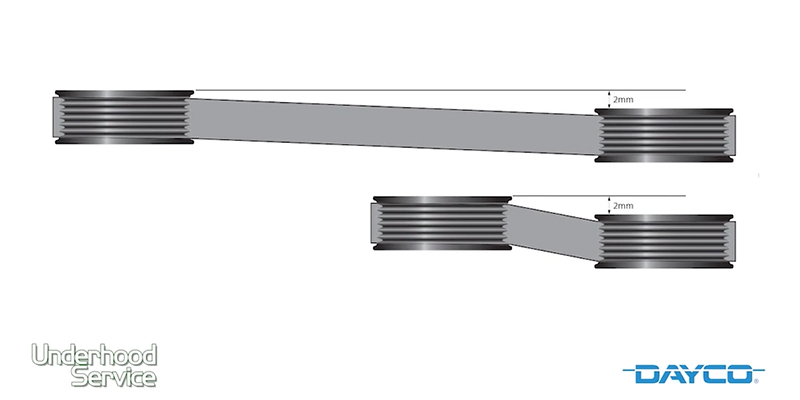

VIDEO: Belt Plane Alignment

In this Maintenance Minute, Andrew Markel discusses how even 2mm can mean everything when it comes to belts. Sponsored by Dayco.

Drive Belt Checklist: What Are You Missing?

You might have only one chance to sell a customer a new serpentine belt. With belts lasting roughly 90,000 miles, proper inspection at the time of failure is critical not only for selling the belt, but also for ensuring add-on sales and better customer satisfaction.

Toyota V8 Timing Belt Service

Each of the various Toyota models that use the V8 have specific items that must be removed to allow access to the timing belt and allow room to remove the accessories, belt drives and timing covers.

Selling Timing Belt Replacement Jobs

When pricing the job, don’t overlook additional and necessary related sales. The timing belt drives the water pump on these engines. Although very reliable, I would consider it a bad bet to think the pump will last 180,000 miles.

Diagnosing Belt Slippage

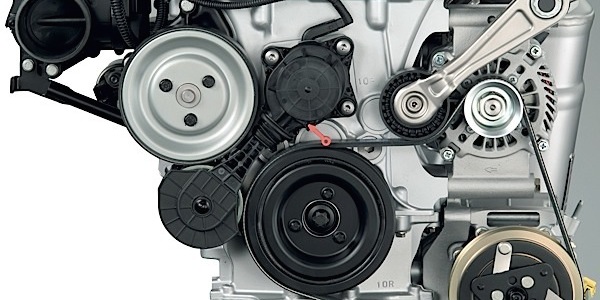

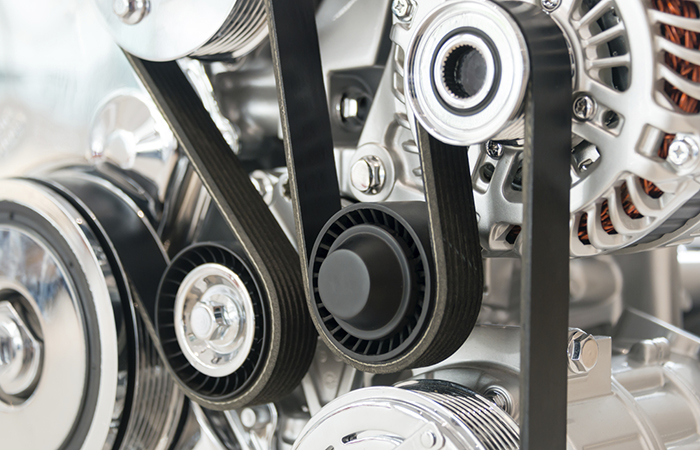

A belt is merely an indicator of the condition of the components with which it is connected. Like a brake pad or tire, it is designed to wear. But, the wear can be impacted by the total system.

VIDEO: Overheating In The Summer Heat

Andrew Markel shows how you can diagnose the overheating vehicles that will be coming to your shop in the hot weather. Sponsored by Auto Value and Bumper to Bumper.

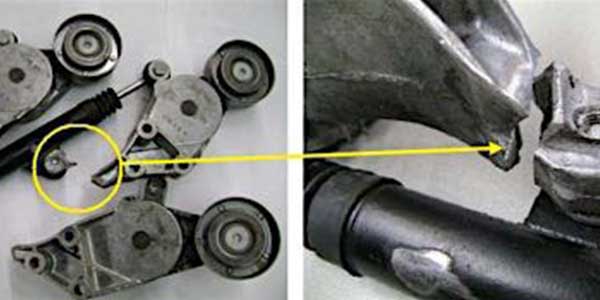

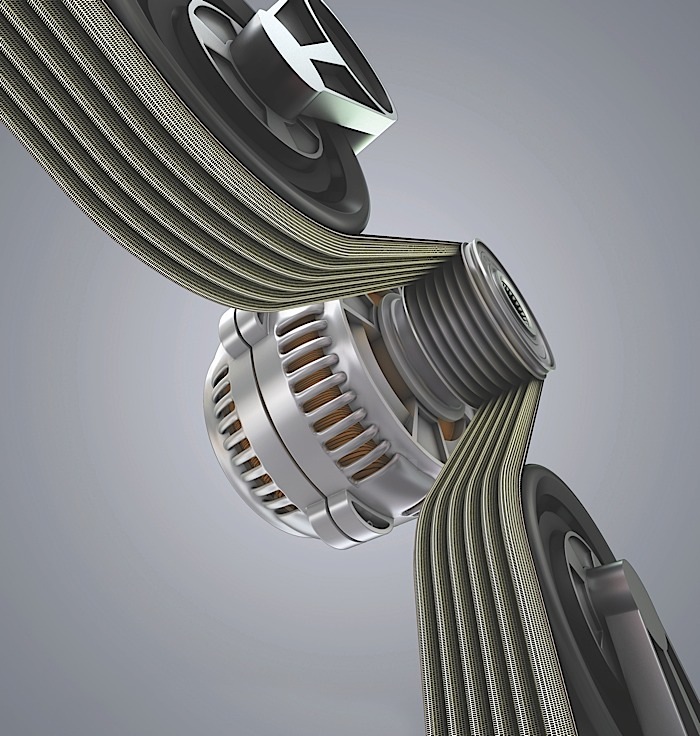

VW Beetle, Golf And Jetta: Broken Tensioner, Root Cause Of Failure Is Alternator Pulley

This type of failure is the result of severe vibrations in the accessory belt drive system. While a broken tensioner may be the result, the root cause often lies elsewhere in the system.

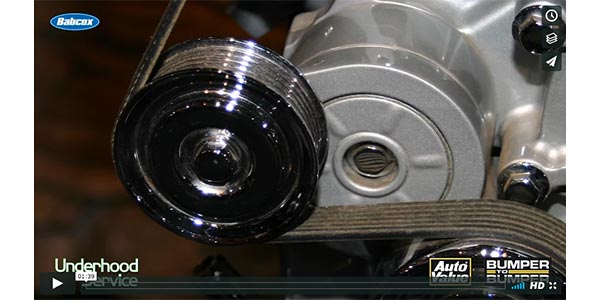

VIDEO: Five Tips To Diagnose Belt Noise

Andrew Markel shares five useful tips to diagnose and resolve belt noise, including twisting the tensioner, measuring the grooves, and ensuring the belt and pulleys are properly aligned. Sponsored by Auto Value and Bumper to Bumper.

5 Tricks To Solving Belt Noise

Engineering a belt system is one of the most difficult jobs for OEMs. There are contact, frictional, centrifugal and peripheral forces that must be taken into account. If they get it right, the belt will be quiet, efficient and last 100,000 miles. If they get it wrong, the belt will be noisy or rob the engine of power. For technicians, the job is even tougher. Variables that the engineer did not factor in can put the belt and your diagnostic skills to the test. But there are four techniques you can use to solve belt noise problems.

Accessory Belts, Tensioners And Misfires: A Balancing Act

Ever been amazed how complex some belt routing diagrams can be when all they are driving is an alternator, A/C compressor and maybe a power steering pump? The belt might be 8-feet long and loop around one or two idler pulleys.

Stretch Belts: Inspection And Installation

When inspecting a stretch belt, always measure the depths of the grooves with an inspection tool since the differences between a worn belt and a good belt can’t be seen or felt. The new materials used to make a stretch belt might crack or separate like older belts before the grooves are worn.

Selling the Complete Serpentine Belt Job

Technicians and customers have pretty much accepted that the accessory serpentine drive belt should be replaced between 90,000 to 100,000 miles. It is a “slam dunk” sale to just replace the belt, but does that replacement belt have the same chance to survive the same mileage? Chances are in the next 90,000 to 100,000 miles