CRP Automotive Offers New Rein Automotive Aluminum Water Pump Pulley Kit For BMW

The upgrade kit features a superior aluminum pulley in place of the OE plastic design, according to CRP.

Curing Belt Slippage

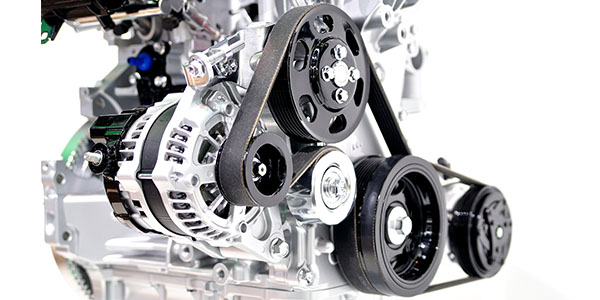

If an engineer could design a belt system that would never slip it would be a miracle. This perfect belt system would last a long time because without slipping, there would be very little wear. But, it is not that simple. Too much tension would increase the loads on the engine and the strain on a belt is not constant. It is a balancing act between drag, slippage and belt wear.

Servicing Decoupler Pulleys

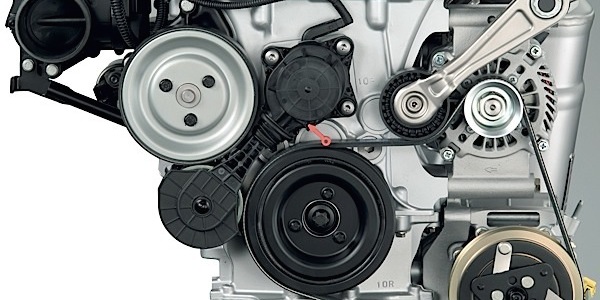

Alternator pulleys are not so simple anymore. Many late-model vehicles are equipped with special pulleys that are engineered to reduce NVH (noise, vibration and harshness) and extend the life of the alternator. An Overrunning Alternator Pulley (OAP) has a one-way clutch mechanism inside the hub that allows the belt to turn the alternator in one direction, but allows the alternator to “free wheel” and spin at its own speed when the engine suddenly decelerates.

Drive Belt Checklist: What Are You Missing?

You might have only one chance to sell a customer a new serpentine belt. With belts lasting roughly 90,000 miles, proper inspection at the time of failure is critical not only for selling the belt, but also for ensuring add-on sales and better customer satisfaction.

5 Tricks To Solving Belt Noise

Engineering a belt system is one of the most difficult jobs for OEMs. There are contact, frictional, centrifugal and peripheral forces that must be taken into account. If they get it right, the belt will be quiet, efficient and last 100,000 miles. If they get it wrong, the belt will be noisy or rob the engine of power. For technicians, the job is even tougher. Variables that the engineer did not factor in can put the belt and your diagnostic skills to the test. But there are four techniques you can use to solve belt noise problems.

Belt Wear Diagnostics

The original equipment belts on late-model vehicles are made of synthetic materials and are far more heat-resistant and wear-resistant than older materials. These innovations mean serpentine belts may last up to 100,000 miles before they need to be replaced. If a belt fails sooner, you need to be a detective and investigate why it failed.