During the refueling process, the friction created by fuel being introduced into the system may create static electricity, which can actually cause the ignition of the fuel. Fuel delivery system components concentrate on the use of specific plastics and nylons to reduce conductivity.

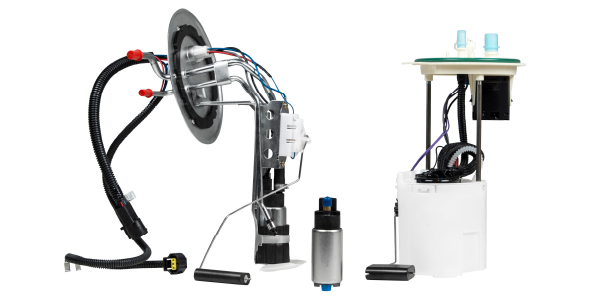

Components such as fuel modules, hangers and fuel filler necks require a grounding path and conductivity apparatus to the vehicle ground system to prevent the build-up of any electrical charge.

Spectra Premium has identified all of the major components that require electrical conductivity, including the use of specific plastics found on fuel pump assemblies and fuel filler necks.

Spectra Premium performs internal testing on all components on the fuel pump assembly that require plastic conductivity (resistance) with the use of special testing equipment. Also, specific vehicle grounds to the fuel pump assembly pressure regulator are necessary to ensure static charge dissipation in the fuel tank. Some fuel filler necks have a ground strap attached to the vehicle body to eliminate any possible static charge, especially during refueling.

Others require a special conductive paint that grounds the fuel filler neck to the vehicle and discharge any static charge. The latest ESD testing equipment is utilized in Spectra Premium’s development and manufacturing process to ensure that Spectra’s products meet or exceed all OEM requirements for ESD safety.

Courtesy of Spectra Premium