There are a variety of reasons why a spark plug may fail, but one that seems the easiest to correct often causes most of the issues. According to one premium spark plug manufacturer, most failures stem from improperly applying torque to the plugs when they are installed.

A plug that is torqued correctly allows it to dissipate heat out of the combustion chamber and into the cylinder head. If you don’t use a torque wrench, it can lead to over-torqueing or under-torqueing a spark plug, which can cause damage to the plug and possibly the cylinder head as well.

Some applications are more challenging to remove spark plugs than others. Using the manufacturer’s recommended procedure significantly reduces the chance of breaking a spark plug, which is a major headache if it happens. There are special tools to help remove the broken spark plugs, but you may need to charge additional labor for the removal of each broken plug.

When fine-wire spark plugs were first introduced, many broken electrodes were reported because of incorrect gap tools and procedures. Many technicians falsely assumed you could not adjust the gap on a precious metal plug. Although some spark plug manufacturers pre-gap their plugs, there are some instances where a spark plug gap may require adjustments. When gapping a fine-wire spark plug, it is recommended that you use a wire-style or feeler gage gap tool, which can adjust the gap without prying against the very fragile center electrode.

BMW X5

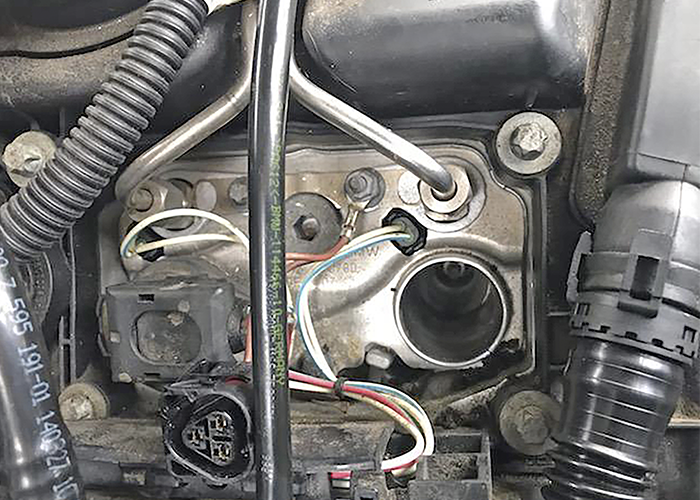

Our test subject for this case study was a 2011 BMW X5 with a 3.5L Turbo 6-cylinder engine that had a misfire at low rpm. A common issue with these vehicles is that the partition that covers the rear two cylinders of the engine tends to crack allowing water to leak on top of the valve cover, eventually finding its way to the coil pack and spark plug well.

Our X5 had cylinder #6 spark plug and coil pack submerged underwater. However, there was no issue with a misfire until we changed the plugs. After pulling the covers off and discovering the broken partition, the rusted coil pack didn’t look good either, but the customer only wanted us to change the plugs initially. That’s when the misfire began. The owner drove it for about a day with a misfire that continued to get worse and caused the ECU to go into limp mode.

After removing the spark plugs to inspect them closer, we found #6 plug covered in carbon and fouled. We cleaned off the carbon and swapped it with the cylinder #1 spark plug. At this point, the misfire moved to cylinder #1. This confirmed the plug was likely the culprit. To be sure, we installed a new coil pack in #6 as it looked like there was some corrosion around it. The new coil and plug seemed to have cleared up the misfire, but then the owner complained that the engine still idled a little rough at times. So, we connected our scan tool and checked for misfires. All of the cylinders were clear except #6 – it had three misfire events, which is not enough to set off a code.

Diagnosing misfire codes sometimes requires uninstalling and reinstalling ancillary engine components. Approaching the issue like this will often take more time than the actual repair. When a cylinder is not firing, and a misfire begins adding up consistently, a litany of things might be the cause – the injector, coil or spark plug, low compression, a valve seating issue, and so on. A lab scope can be used to perform a current ramp test to reduce diagnostic time and help you better explain to your customer what was at fault.

Ignition coils can break down from heat and vibration, creating an open circuit. An ignition coil uses a sealed epoxy coating and tight primary and secondary windings to ensure the longevity and performance in an environment of heat and vibration. In some cases, coils, spark plugs or injectors are very easy to swap around to see if the misfire follows. But many modern V6 or V8 engines can require hours to remove the intake manifold to reach the back cylinders.

A spark plug has a demanding job firing at 300 times per minute (@1000 rpm) per cylinder. Despite how much work spark plugs perform; replacement intervals are often neglected. Letting customers know the importance of routine plug changes can alleviate potential engine damage from a fouled, damaged or worn spark plug. New plugs can help increase fuel efficiency and performance and allow faster start-ups for a relatively nominal maintenance cost.