itially adjusted the carb’s idle mixture screws to two turns from the seated position.

A squirt of carb cleaner into the air horn slightly increased the idle speed, indicating that the idle mixture was nearly correct. Unfortunately, the stalling condition didn’t go away.

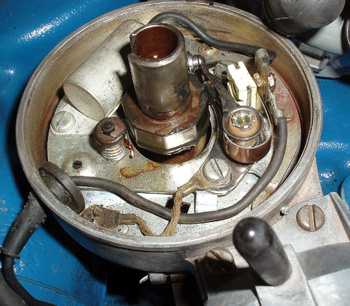

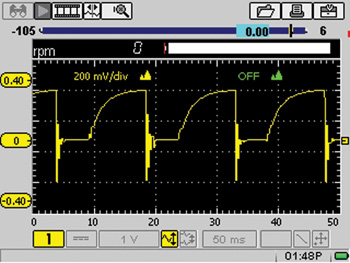

I keep an old Snap-on 1665 ignition scope on hand that I bought new. It’s no longer serviced, but it still works well for diagnosing distributor ignitions. A secondary spark analysis showed a rather trashy secondary pattern that was missing the secondary oscillations typical of contact point ignitions.

Unfortunately, I didn’t photograph the screen. The other revelation provided by the scope was that the Mustang’s year-old alternator was no longer charging the battery.

Unfortunately, I didn’t photograph the screen. The other revelation provided by the scope was that the Mustang’s year-old alternator was no longer charging the battery.

Two Diagnostic Scenarios

Digging deep into my memories of 40 years ago, I recalled rare instances in which poor spark output caused the vehicle to stall when placed in gear. One scenario is that, when the automatic transmission is placed in gear, the engine idle speed slows and reduces alternator output.

The other scenario is that, when a mild load is placed on the engine at idle, the load on the ignition coil increases to the point that it will no longer fire the cylinders.

See Photo 4.

Because I’ve never found a reliable method of diagnosing bad ignition coils, I’ve kept several known-good coils on hand for scope testing. With great relief, I found that replacing the ignition coil cured the stalling complaint.

Lessons Learned

Lessons Learned

Several lessons are to be learned from this experience.

First, any vehicle can come through the door with multiple failures which, in this case, were high resistance in the primary circuit and a faulty ignition coil.

Second, it’s important to understand that the operation of any marginal electrical component like the ignition coil can be affected by low battery or charging voltage.

Last, a rich air/fuel ratio supports a weak spark better than a lean A/F ratio. Consequently, a weak coil might perform better at a rich wide-open-throttle than at a lean idle condition. It’s old-school technology, but it applies to modern vehicles as well.