By Keith Loch

ACDelco

ACDelco now offers the 4WD transfer case actuator motor and range selector position sensor for 2003-2007 GM full-size trucks.

Both the actuator motor and sensor (part number 88962314) or the sensor only (part number 88962315) can be ordered.

It is often more cost-effective to replace the sensor, but care must be used in the replacement procedure. On these vehicles, the transfer case actuator assembly consists of a permanent magnet DC motor and gear reduction assembly.

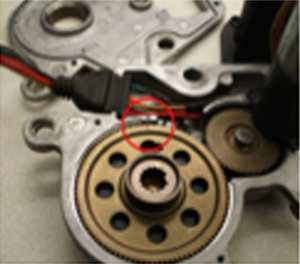

When activated, it turns the shift detent lever shaft to shift the transfer case. The motor/encoder is controlled with a pulse-wide modulated (PWM) signal by the transfer case shift control module. When replacing the actuator motor or sensor (see Photo 1), shift the transfer case to Neutral prior to removing any components. This will make it easier to reassemble.

Sensor Replacement

If only the sensor is being replaced, be sure to assemble the harness to the new encoder with the connector legend TOP and the encoder part number facing up. With the output gear/encoder assembly in hand, carefully align the casting and output gear timing marks.

At the same time, align the encoder phasing post with the phasing slot in the casting (see Photo 2) before inserting the shaft into the bushing. Also press a new seal into the cover before installing the cover.

Shift Abuse

The transfer case may stop shifting on these vehicles if the transfer case shift control module senses repeated shift requests in a short period of time. The control module software has a shift abuse lockout mode to protect the module and encoder motor. If the driver tries to shift into and out of different modes continuously, the control module will stop trying to shift for several seconds to prevent abuse damage from occurring. Cycling the ignition off for 30 seconds or more should allow the transfer case to resume normal operation.

Learn More

ACDelco offers on-demand, online, Web-based courses and a variety of instructor-led, hands-on courses. To learn when ACDelco seminars will be scheduled in your area, visit www.acdelcotechconnect.com or contact your local ACDelco distributor.