#160;

GM Enhanced EVAP Testing Using the Tech 2 (Functional Test)

DIRECTIONS:

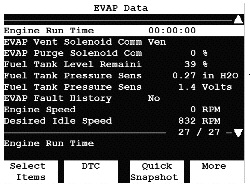

1. Turn the ignition key to the On position (do not start the engine). Allow one minute for the EVAP system to stabilize. Using your navigational skills with the Tech 2 scan tool, find the data list that shows the voltage and vacuum values for the FTP sensor.

2. You must now proceed to check the nominal voltage of the FTP sensor per the scan tool, a range of 1.3 to 1.7 volts should be noted. Note: The gas cap must not be removed. Record your observation below:

Record the nominal voltage that you noted on the Tech 2:

________ volts.

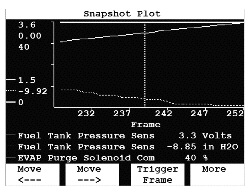

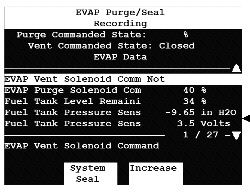

3. You may now start the engine and proceed to the EVAP testing area of the scan tool. It is important that you first verify that the proper vacuum is available to the purge solenoid at idle. This will enable the system to be able to generate a vacuum and also perform a system seal. The suggested purge solenoid duty cycle test percentage is 30%.

4. Did this system have the ability to generate a vacuum?

_______ Yes ________ No

It is not uncommon for these systems to generate anywhere from -8 to -12” of water. Did your system generate vacuum levels within this range? ________ Yes ________ No

Note: If the system is not able to generate a vacuum, the reason may be due to a gross leak failure. If the system is able to generate a vacuum, but will not hold or maintain its vacuum levels, it may be due to a small leak failure.

5. Did this EVAP system maintain vacuum once it successfully built to an acceptable level? _______ Yes ______No

Note: Check to see if over time the system is able to maintain acceptable vacuum levels. An acceptable rule of thumb: FTP voltage should not decrease by more than 0.4 volts in 20 seconds.

6. How long was the system able to hold its obtained vacuum levels? _________ seconds.

Based on the data you have obtained for this system, is this system working as designed or does it need further analysis?

_______ working as designed.

_______ further analysis is needed.

Once you have confirmed that a fault is present, prepare your smoke machine to find the leak.