I have been intrigued by automotive engineering and design since I was about 10 years old. The auto show was a big deal each year, and we always attended to get a chance to sit in some of the new cars from all over the world. In the 1950s, looking at the foreign cars was a big hit for me, simply because the small cars better matched my size, and they seemed to have fewer gadgets on them.

The dashboards had gauges and that was quite different than the American cars of that time; they just had “idiot” lights. I do remember, however, that the early cars from Porsche were a little different. The engine was in the back, there was no big grille on the front and there were very few gauges on the dash. Mostly just a speedometer and a tachometer, whatever they were for!

Times have changed since then, but my interest in automotive engineering still drives me to try and learn as much as I can about how stuff works, and why it was done a certain way. Today’s engineers and designers have a difficult balance to arrive at a vehicle that will meet government standards, look and drive well, and get reasonable fuel economy.

Porsche has been the leader in automotive design and engineering, for virtually all of my life. It has been building engines for decades that will literally fit in a suitcase, but are still able to put out horsepower that many larger engines can’t match.

In this article, I will present a few of the more common diagnostic challenges that we have seen with the Porsche Boxster, and prepare you to dive into one of these cars if it shows up on your lot. One of my favorite expressions concerning “exotic” cars is that, in fact, they are just cars. That Porsche is able to wrap all of the government-required bits into this tiny body and still make it look right on the outside is the ultimate expression of automotive engineering. Like candy with the perfect sugar coating and cream center.

The Basics

The Porsche Boxster is a little different in layout than most cars, even other Porsche cars. It has been around for more than 10 years and its mid-engine design has been refined to the point that it is more than just an entry-level vehicle. The Boxster came along at a time when Porsche sales were falling, and with automated production methods has been a sales leader of the Porsche line.

The Porsche Boxster is a little different in layout than most cars, even other Porsche cars. It has been around for more than 10 years and its mid-engine design has been refined to the point that it is more than just an entry-level vehicle. The Boxster came along at a time when Porsche sales were falling, and with automated production methods has been a sales leader of the Porsche line.

Yearly changes have been kept to a minimum, but some significant changes have made the car more reliable. Most of this article will be aimed at the earlier models (1997 to 2000), as these cars are being snapped up by a lot of non-Porsche types looking for a fun, different kind of transportation.

For most repairs, all of the tools you would normally need to service other German-made cars are all that will be needed. In most cases, a scanner with OBD II and CAN bus capabilities will be sufficient to access codes for the drivetrain, but Porsche-specific software will be needed for body control modules and for reset procedures in the event of an electrical failure. Access to online or on-demand service information will be a big help as each year has some specific differences and updates that can help resolve faults.

For cooling system repairs, a vacuum filling system is highly recommended. A lot of wasted time can be eliminated by having the owners’ manual handy to allow access to the engine compartment, as there are a few steps necessary to partially open the top and remove the upper engine cover. There is an access panel behind the seats that provides room for repairs to the accessory drives at the front end of the engine.

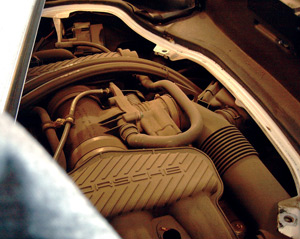

One other special tool needed to work on these cars is patience (See Photo 1). Several components are difficult to see, let alone service. In many cases, several components unrelated to the repair must be removed to complete repairs, so attention to what is involved is important to cover the costs of a repair. Like some other manufacturers, flat-rate times are not always realistic until engine access panels and other considerations are taken into account. There are also a lot of plastic pipes, hoses, covers and caps (See Photo 2) that become very brittle at low mileage; some of which cannot be taken apart without damage.

One other special tool needed to work on these cars is patience (See Photo 1). Several components are difficult to see, let alone service. In many cases, several components unrelated to the repair must be removed to complete repairs, so attention to what is involved is important to cover the costs of a repair. Like some other manufacturers, flat-rate times are not always realistic until engine access panels and other considerations are taken into account. There are also a lot of plastic pipes, hoses, covers and caps (See Photo 2) that become very brittle at low mileage; some of which cannot be taken apart without damage.

Misfires and Fuel Trim

Almost all of the common fault codes we’ve seen with these cars are related to fuel control and misfires. We have customers who use these cars for everything from commuter service to weekend warrior duty at the track, and some use them for both. Many of the male owners we see have already added some kind of performance items before they start to have problems.

As with any diagnosis, a look at the basics must come first. A talk with the customer about use, maintenance and length of ownership is always a good idea for new customers, but with these cars the discussion should be very detailed. Aftermarket performance parts are readily available for these models, but can contribute to both MIL illumination and driveability complaints.

Fuel trim faults can often be traced to vacuum leaks or engine sealing faults due to the remote location of the engine service module in the trunk. Whenever you have fuel trims that set codes such as P1123 or P1125, start by looking for signs of oil seepage. Often the presence of oil on the bottom of the engine (See Photo 3) will lead to a cracked breather or air intake hose. Look carefully around the plastic intake manifold for signs of excessive heat or listen for leaks with the engine running. A smoke generator works great for finding even the smallest of leaks that can cause fuel trim faults that may affect only one bank or both.

Fuel trim faults can often be traced to vacuum leaks or engine sealing faults due to the remote location of the engine service module in the trunk. Whenever you have fuel trims that set codes such as P1123 or P1125, start by looking for signs of oil seepage. Often the presence of oil on the bottom of the engine (See Photo 3) will lead to a cracked breather or air intake hose. Look carefully around the plastic intake manifold for signs of excessive heat or listen for leaks with the engine running. A smoke generator works great for finding even the smallest of leaks that can cause fuel trim faults that may affect only one bank or both.

Because there is no actual PCV valve, any leak in the engine plumbing related to crankcase fumes or intake passages will cause fuel trim faults. Using propane on these cars might be a little difficult due to the layout and placement of the engine. It would however give you a “general” area in which to look for leaks.

MAF problems are no more prevalent on these cars than most others. With higher mileage comes deposits on the sensor that can be removed occasionally with MAF cleaner. Although many shops still use electrical contact cleaner for MAFs, a specific cleaner for this purpose is a better idea. Aftermarket, oiled air filter elements are still pegged for some MAF failures, but usually when the servicing involves not taking the proper steps, not using the proper oil or too much of it.

Typical misfire codes like P0300, P0301, etc. can be diagnosed like any other car. Ignition coil failures are common (See Photo 4). Probably the easiest way to determine if the coil is the cause of a single-cylinder miss is to swap the coil from the indicated cylinder to another and see if the code (after clearing) returns to the same cylinder or moves with the coil. So far, wiring harness faults have not been a pattern failure.

Typical misfire codes like P0300, P0301, etc. can be diagnosed like any other car. Ignition coil failures are common (See Photo 4). Probably the easiest way to determine if the coil is the cause of a single-cylinder miss is to swap the coil from the indicated cylinder to another and see if the code (after clearing) returns to the same cylinder or moves with the coil. So far, wiring harness faults have not been a pattern failure.

Performance vehicles always seem to attract discussions about which spark plug is best for all-around use. There are just too many factors related to use that makes one spark plug ideal for every purpose. To eliminate the possibility of spark plug-caused misfires, stay with the factory-recommended plugs. Going up or down a heat range may make a difference for commuter or racing use, but the standard plugs are probably best for all-around use.

Performance vehicles always seem to attract discussions about which spark plug is best for all-around use. There are just too many factors related to use that makes one spark plug ideal for every purpose. To eliminate the possibility of spark plug-caused misfires, stay with the factory-recommended plugs. Going up or down a heat range may make a difference for commuter or racing use, but the standard plugs are probably best for all-around use.

Something to watch for regarding the O2 sensors is their location. The primary (upstream) sensors (See Photo 5) are mounted near the rear axles and the secondary (downstream) sensors (See Photo 6) are located near the rear bumper. On more than one occasion, I have seen or heard of techs replacing the wrong sensors by failing to properly determine banks and the location of the sensors. The connectors are the slide-lock type, but they still seem to get contaminated easily, which can prompt replacement due to incorrect data, when the only problem is corroded electrical connections.

Something to watch for regarding the O2 sensors is their location. The primary (upstream) sensors (See Photo 5) are mounted near the rear axles and the secondary (downstream) sensors (See Photo 6) are located near the rear bumper. On more than one occasion, I have seen or heard of techs replacing the wrong sensors by failing to properly determine banks and the location of the sensors. The connectors are the slide-lock type, but they still seem to get contaminated easily, which can prompt replacement due to incorrect data, when the only problem is corroded electrical connections.

Secondary Air Injection

Almost all of the secondary air injection system faults we have seen have not been the air pump; at least not just the air pump. The air pump should run for up to 50 seconds on a cold start, and may run intermittently to keep the catalysts warmed. We all know that the purpose of the secondary air system is to add additional oxygen to the exhaust to help keep the cats at peak temperature whenever the engine speed is not sufficient to do the same.

If the pump runs but there is no reaction from the O2 sensors, the next step is to check for any leaks in the hoses for the air system. Mentioned above, these plastic hoses tend to get extremely brittle and will often crack if they are disturbed. A smoke test will usually find leaks easily.

If the hoses are all intact, the next most likely culprit will be the air injection valves. On the Boxster, these are located under the intake manifold on each side of the intake plenum. They are difficult to access to test with a vacuum pump. The diagnosis is mostly one of elimination for secondary airflow faults. If the pump runs (and doesn’t scream), the hoses are all intact and a smoke test shows no leaks, then the most likely failure is one, or both, valve(s).

Cooling System

Packaging on the Boxster requires that the cooling system be parceled out throughout the car. Two small radiators with small fans are tucked into the front fenders just behind the bumper. There are tubes running from the radiators through the center tunnel to the rear. There are numerous points for leaks to occur, and, as I noted in a previous article, water pumps fail (See Photo 7). Repairs to the cooling system are straightforward, but mostly time consuming and require removal of other components for access.

Packaging on the Boxster requires that the cooling system be parceled out throughout the car. Two small radiators with small fans are tucked into the front fenders just behind the bumper. There are tubes running from the radiators through the center tunnel to the rear. There are numerous points for leaks to occur, and, as I noted in a previous article, water pumps fail (See Photo 7). Repairs to the cooling system are straightforward, but mostly time consuming and require removal of other components for access.

In one case on a low-mileage Boxster, I had looked for obvious coolant loss everywhere that seemed logical, only to find coolant dripping off the rear bumper, from the trunk! The coolant reservoir is mounted, along with the oil filler and dipstick, in the rear luggage compartment (See Photo 8). The hardest part of the replacement was trying to get the clamps off (inside the engine bay) and removing the hoses without breaking anything else in the process. I would highly recommend a vacuum fill to prevent damage due to air pockets and temporary overheating.

In one case on a low-mileage Boxster, I had looked for obvious coolant loss everywhere that seemed logical, only to find coolant dripping off the rear bumper, from the trunk! The coolant reservoir is mounted, along with the oil filler and dipstick, in the rear luggage compartment (See Photo 8). The hardest part of the replacement was trying to get the clamps off (inside the engine bay) and removing the hoses without breaking anything else in the process. I would highly recommend a vacuum fill to prevent damage due to air pockets and temporary overheating.

No-Start Condition

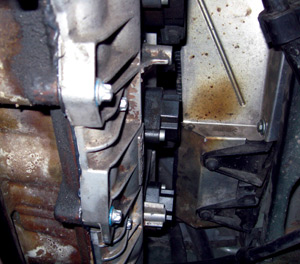

I won’t go into much detail here, but we have seen ignition switch failures, immobilizer and key problems, and several starter failures. The starter lives in a harsh environment, but I have also found several cars with loose positive starter connections. Replacement of the starter or just access for testing is “fun” (See Photo 9). Don’t forget to pull the carpet or mat out from under the clutch pedal before going after a no-crank problem!

I won’t go into much detail here, but we have seen ignition switch failures, immobilizer and key problems, and several starter failures. The starter lives in a harsh environment, but I have also found several cars with loose positive starter connections. Replacement of the starter or just access for testing is “fun” (See Photo 9). Don’t forget to pull the carpet or mat out from under the clutch pedal before going after a no-crank problem!

Finishing Up

There is nothing about these cars that makes them especially difficult to diagnose or repair. The packaging is the main challenge. Learning where components are hidden and how access is gained for service is more than half the battle. All kinds of information on Porsche service and repair is available from many sources. If one of these little cars shows up for service, don’t pass on it. Treat it like any other car, and then take it for test drive, unless you are close to having a mid-life crisis.