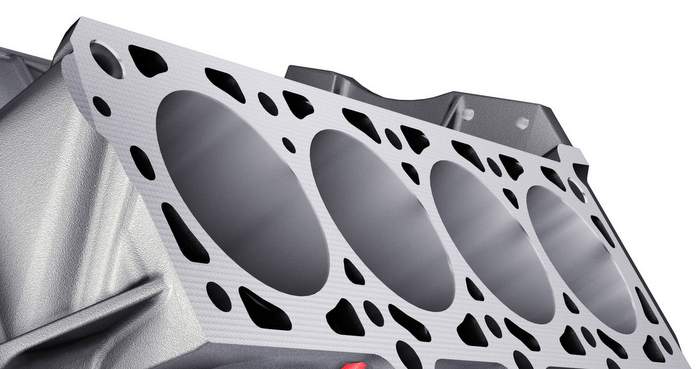

Porosity refers to any void or hole found in a casting. These voids can be caused by gases and contaminates present during the casting process and typically occur near the outer parts or at the top of a casting. Honda, GM, Chrysler and other OEMs have all had issues with the porosity of some castings.

These voids do not typically pass all the way through the casting. They can be as large as 3 mm and as small as 0.25 mm. They are typically exposed when a surface is machined. These voids prevent the gasket from sealing a machined surface.

Some of these problems are caught while the vehicle is under warranty, but some times porosity problems occur as the gasket ages and hardens. If there are enough voids, fluids can flow and seep in between, leading to leaks, but nothing more significant than a few drops on the garage floor.

Detection

Oil leaks due to porosity in the casting can be detected using three methods. First, dyes can be added to the oil. Second, you can pressurize the system with compressed air and look for leaks with a brush and soapy water. Third, using athlete’s foot spray, you can spray an area and examine it for leaks.

Solutions

Solutions

Porosity at the mating surfaces can be solved three ways.

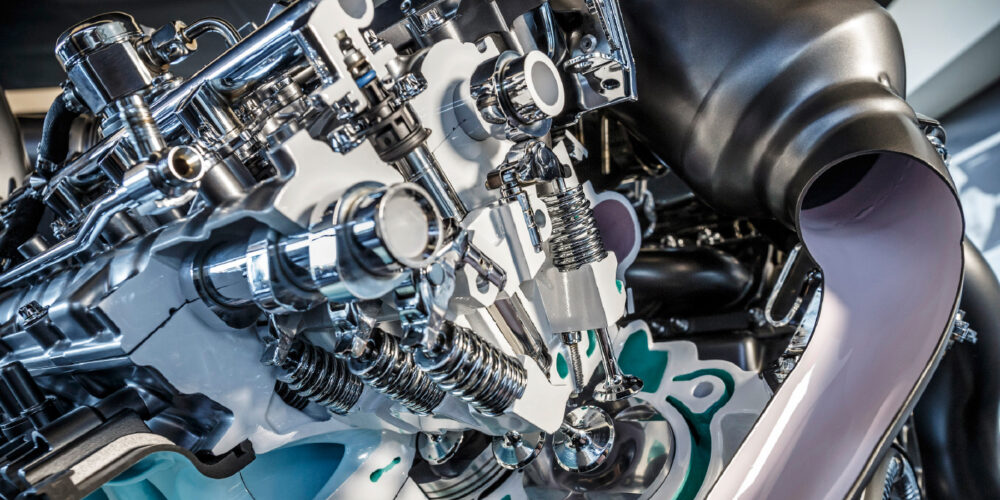

First, you can apply RTV sealant or epoxy compound to the voids and mating area. Excess sealant can clog oil passages in the lifters and variable valve timing components. Second, you can replace the component. This may work for a front cover, but will not work for a complete engine block. Third, you can use better gaskets. Most gasket manufacturers are aware of porosity problems and can use better materials to seal a surface.

Cleaning the mating surface with an abrasive disc is recommended, but grinding away at the mating surface and removing metal is not. This will only cause more leaks and maybe expose more voids.

Aftermarket Parts

Porosity can be an issue with some aftermarket parts that are made of cast aluminum. If you ever encounter a water pump, front cover or replacement oil pan with excessive porosity at the gasket mating surfaces, send it back.

GM LS Problem

The porosity problem crops up on the LS V8 made between 2004 and 2011 that uses an aluminum block. TSB 05-06-01-034 covers the issue. On inspection, the oil leak may appear to be a failed oil pan gasket or leaking rear main seal, but the source of the leak is the oil crossover port above the camshaft that is sealed by the rear cover. GM sites the cause of the leaks as porosity on the mating surfaces of the engine block and rear cover.

GM recommends replacing the rear cover if there are a lot of voids on or near the mating surface. If the voids are on the block, GM recommends using RTV to fill and seal the voids.

Use a high-quality gasket in these applications. Aftermarket replacement gaskets are available to solve this problem.

Honda V6 Problem

Casting porosity can be a problem for the aluminum block on 1998-2003 Honda V6 engines. This leak occurs in the valley of the engine and can cause leaks at the front middle or rear of the engine. Honda’s solution is to apply “JB Weld” to the block in the leaking area.