“Pneumatics is a section of technology that deals with the study and application of pressurized gas to affect mechanical motion.” — Wikipedia

Said differently, pneumatic tools use compressed gas (usually air) to make them work. I would venture to guess that most, if not all, of you reading this use air tools frequently, or have used them at some time in the past. I am not so confident that very many of us have given too much thought to air tools and how they work though.

Said differently, pneumatic tools use compressed gas (usually air) to make them work. I would venture to guess that most, if not all, of you reading this use air tools frequently, or have used them at some time in the past. I am not so confident that very many of us have given too much thought to air tools and how they work though.

There are a handful of inventions that continue to amaze me. Just between us, some of these tools make me believe in magic! One such tool is the modern (not so modern!) fax machine. If you think about it, this is truly a modern-day transporter. (Star Trek fans will confirm this!) You take a physical item — a piece of paper, you put it in the machine and voila! it appears somewhere else in the exact form it was before! It’s either magic or Scotty just hit energize.

For me, pneumatic tools also fall into this category of magical inventions. You take regular air and compress it to a pressure somewhere between 75 and 150 psi. Then you send that air from the compressor through a flexible hose to tools of all kinds. This same air that is invisible and pressurized at 75-150 psi ends up powering work of all kinds. It can loosen or tighten bolts with hundreds of pounds of torque, it can cut, grind, polish, paint and the list goes on. Pretty cool, huh?

Although the basic configuration of many air tools remains unchanged, there are some new tools, and improvements on those tools. I will be discussing some of these new innovations and new tools in this article.

While there are many ways to evaluate air tools, some of the most common areas are: noise, speed, power (torque), weight and efficiency. There are also some new configurations for air tools. All of these are important and all of these continue to be areas that engineers spend their time trying to improve. Here are some things to consider when you go to purchase tools for your own use.

Noise

This is an area that we all used to ignore. We assumed that air tools were supposed to be loud. In fact, it was a badge of honor to have the loudest tool in the shop. It was like putting headers on a small block Chevy. Louder is better, right?!

It turns out that all those years of listening to the whine and chatter of air tools can be detrimental to your hearing. Huh? What was that? Air tool manufacturers are spending large amounts of time, money and effort to reduce the noise signature of their tools. This, like many things, is a game of inches and just reducing sound by as little as one or two decibels can make all the difference. When purchasing air tools, be sure to compare the decibel ratings of the tool. All the best air tool manufacturers provide this specification on the tools they offer.

Speed

This is an area that applies mostly to rotary tools, such as drills, polishers and grinders, but can also apply to tools that have stroking motion, such as nibblers, saws, etc. The difference is in the unit of measure. Rotary tools are measured in rotations per minute or RPMs while the other tools are generally measured in strokes per minute or beats/blows per minute (SPMs or BPMs). In either case, be sure to compare the rating among the tools you are looking at as well as evaluate the rating for the jobs you need to do. This can be critical for certain applications: specific materials, using specific chemicals or blades.

One area of improvement in this category is speed controls. Depending on the tool, this may be a trigger or a setting; and in some tools, a combination of both. Some of the nicest improvements we have seen in this area are speed controls for impact wrenches. Recently, some suppliers have introduced a new way to control speed and direction on impact tools. A large paddle lever at the rear of the tool is a nice feature that allows the user to quickly decide what setting is needed. This control works well with greasy hands.

Power

This rating is one that is more debated than what was the greatest World Series team. Generally speaking, anytime you can attach a specification to a product that can increase its value or desirability, it’s an invitation for people and companies to misbehave. While this phenomenon will never go away, the largest and best companies are pretty accurate about this spec. In the old days, it was difficult or impossible to get access to a Skidmore or similar tester to verify torque ratings. Today, the tester is more readily accessible, which tends to minimize the fantastic claims made by unscrupulous manufacturers.

Torque only applies to some of the air tools available. Generally speaking, this will be your fastening tools, such as impact tools. This is tied directly to the need to remove stubborn fasteners that have rusted or corroded or were torqued in place from the installation.

Weight

Weight is an area that has seen some amazing improvements and innovations. Like many segments of the automotive aftermarket, air tool manufacturers are now regularly using alternative materials in the tools they manufacture. These tools sometimes are called hybrids, meaning they are made out of two or more materials. Companies are using products such as resins, carbon fiber and various plastic composite materials. This allows the suppliers to reduce weight on the tools you use every day.

The savings can be quite substantial with no detrimental effect on the tool’s performance or an increase in cost. Impact wrenches seemed to have gained the most benefit from the use of these materials. These are some of the most often used and heaviest of any air tools in your toolbox. The next time you need to purchase an air impact tool, consider looking at some of these amazingly lighter new products.

Efficiency

This is an area that is both highly technical and can also be highly subjective. Many of the technicalities of this are beyond this writer, so I will only comment on things that are easily described and discussed. For those of you who have or want a deeper look, there are many great sources of information online, including most of the premiere air tool manufacturers’ websites.

In general, air tool efficiency can fall into two categories. One is power-to-weight ratio. This is a fairly broad attempt to correlate the impact torque rating with the tool’s weight and to express it as a value. It can be a little confusing, but the idea is a good one.

Let’s look at two different tools available today to see how this can work. The first tool is all metal and has a max torque of 600 ft.-lbs. and weighs 6.5 pounds. This is a power-to-weight ratio of 92:1. Now compare those ratings to a composite construction tool. This tool weighs 3.95 pounds and has a max torque of 780 ft.-lbs. This is a power to weight ratio of 197:1! What this means in the real world is the second tool is considerably lighter, but offers more power than an all-steel tool. This translates to less fatigue for you the user!

The second area of efficiency is much more complicated to explain or understand. Think of a combustion engine, you know that some percentage of every fuel compression is lost, right? For many reasons, there is a percentage of fuel that never is converted to energy. This can be called volumetric loss or volumetric inefficiency. Air tools are very similar in this respect. Some percentage of compressed air that is delivered to the tool doesn’t get converted to work. The air goes out the tool’s “tail pipe” just like in a car. Tool companies are always looking for more ways to decrease this loss. That means more air is used for turning, cutting, sanding, grinding, drilling, etc.

This measurement is one that is hard to appreciate for all kinds of reasons. One is obvious: air is invisible, right? Oh, and it’s free, right?! So the average technician probably doesn’t spend much time thinking about this. If the tool gets the job done and holds up, he is happy.

So I would pose the question, why should we care about efficiency of an air tool? I can give you lots of reasons and they all have zeros at the end of them and pictures of dead presidents on the front! MONEY! If you are the person who has to pay the electric bill at your shop, this might be more important to think about. All that air loss from inefficient air tools adds up. You pay for the electricity to run the compressor to make the air, and a percentage of it goes unused. If it takes extra air to make a tool do work, that is real money you’re losing every day!

The tough part about this is that getting and understanding the ratings about efficiency on air tools is difficult unless you’re an engineer. The main thing you should get out of this is to think about air loss as money and do everything you can to minimize this. New tools help, so does maintaining your equipment, as well as finding and repairing air leaks. All of these things help reduce your energy costs.

Special Configurations

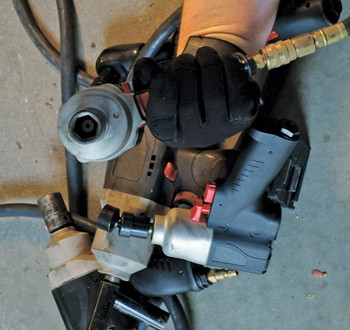

Today’s modern vehicles keep getting smaller, tighter and more difficult to work on. This has created the need for some new tool designs. There are several long-reach tools that have come to market in the last few years, including air ratchets that have extended length to allow you to access confined spaces. There is also a group of ultra-small impact tools that use the case and body of a 1/4” or 3/8” drive tool, but have a 1/2” anvil! These compact tools allow a tech to get in places that standard impact tools won’t fit — and with plenty of power!

There are several reversible grinding tools on the market. This allows techs to get in places to cut or grind without fear of the tool “kicking back” and doing damage to a nearby component.

These are just a few of the new tools that have come to market in the last few years that can greatly improve your efficiency and day-to-day work conditions.

Ask your tool distributor to show you some of these new innovations in tools when you start shopping for that next air tool.

SIDEBAR:

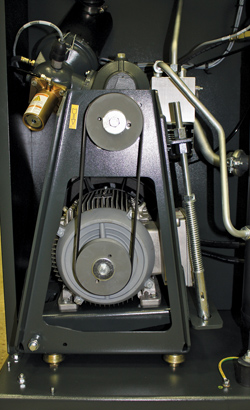

Maintenance Tips: Air Compressors

Regardless of the size or model, all air compressors require some form of periodic maintenance. Below are a few tips to keep in mind.

Regardless of the size or model, all air compressors require some form of periodic maintenance. Below are a few tips to keep in mind.

1. Maintain the package’s pre-filter and inlet air filter elements. Filter elements clogged with dust and debris can drastically decrease the operating efficiency, as well as cause the unit to run at elevated temperatures.

2. Keep psi low. Overpressurizing wears out the compressor and tools quicker and costs you more. Every 2 psi over pressure requires an additional 1% of energy. A 30-hp compressor costs about $12,000 a year to run, but if you can lower pressure by 10 psi, you can save $600.

3. Clean the oil/aftercoolers on a regular basis and maintain proper oil levels.

4. Choose the proper size of compressor (based on CFM) for your particular application. Piston compressors will run too hot if undersized. Rotary compressors may short cycle and run too cool if oversized.

5. Drain the moisture from your tank, and make sure there are no leaks in your system.

6. Check compressed air piping regularly for contaminants like dust, dirt and sludge to ensure optimal tool performance and end product quality.

Information courtesy of Atlas Copco, Curtis Toledo, Kaeser Compressors, M-TM, Quincy Compressor, Sullair Compressors and Sullivan-Palatek.