PFC CarbonMetallic brake pads were the very first pads to become certified as 100% Copper Compliant with AMECA (Automotive Manufacturers Equipment Compliance Agency). With the new Copper Legislation in effect, PFC was ahead of the curve-offering copper free brake pads before the legislation even surfaced, said the company.

PFC CarbonMetallic brake pads were the very first pads to become certified as 100% Copper Compliant with AMECA (Automotive Manufacturers Equipment Compliance Agency). With the new Copper Legislation in effect, PFC was ahead of the curve-offering copper free brake pads before the legislation even surfaced, said the company.

PFC Brakes was the first brake pad company to submit data from copper testing to AMECA, and the first pads to be certified 100% copper compliant. In order to attain certification, testing was done by a third-party laboratory, registered through a registrar while also providing the information publicly, and marking friction materials’ environmental compliance level on the brake pad edge code.

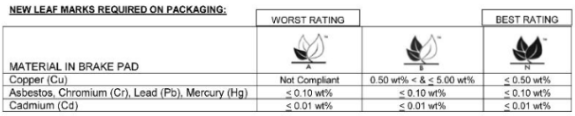

The compliancy levels include the "A," "B" and "N" edge codes. Each edge code represents a different level of legal maximums of the different friction material weight percentages which include: copper (Cu), asbestos, chromium (Cr), lead (Pb), mercury (Hg) and cadmium (Cd). PFC pads have an "N" rating, which has the lowest amount of allowable materials, including copper-containing less than 0.50%.

Leaf Marks that implicate the compliancy level will be required on brake pad packaging starting in January, 2014. This mark will give consumers and installers the ability to tell if the brake pads are safe and environmentally compliant-straight from the box.

Leaf Marks that implicate the compliancy level will be required on brake pad packaging starting in January, 2014. This mark will give consumers and installers the ability to tell if the brake pads are safe and environmentally compliant-straight from the box.

PFC Brakes has been distributing copper free brake pads through major automakers since 1982 and new generation copper-free Carbon Metallic pads are currently being sold for OE production. Without sacrificing brake pad quality, CarbonMetallic pads are the most eco-friendly on the market and contain no harmful substances.

PFC CarbonMetallic proudly meets all environmental requirements by being 100% copper compliant and containing no asbestos, no chromium, no lead, no mercury, no cadmium, no antimony, and no cancer-causing ceramic fibers — NO COMPROMISES.

To look at AMECA certifications, visit the AMECA website at www.ameca.org.

To obtain a copy of PFC’s certificates, contact Skip Carroll at [email protected].