Oil level sensors have been used on import and domestic cars for more than a decade. Some of the first applications only monitored if the oil level was low using a switch attached to a float. The sensor would just trigger a message or light in the instrument cluster and only measured oil levels when the engine was not running.

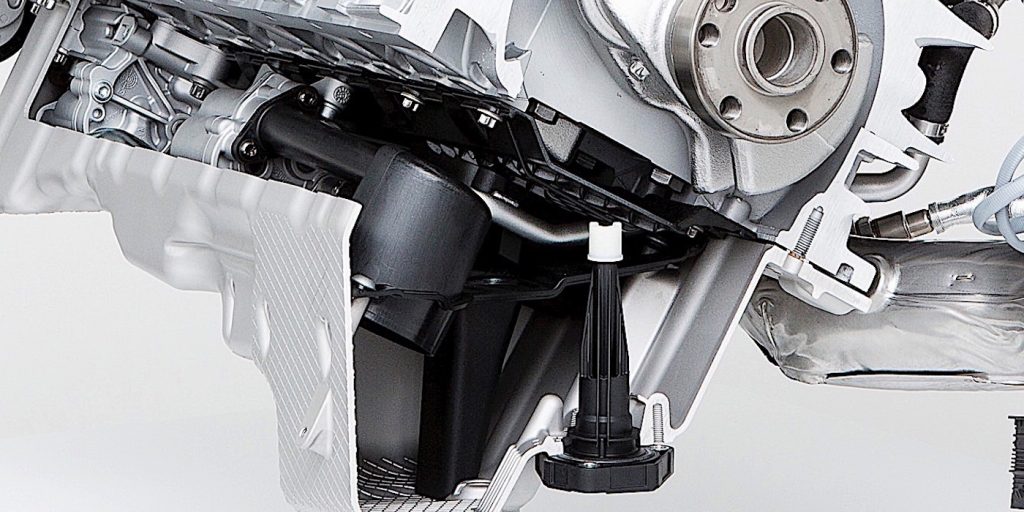

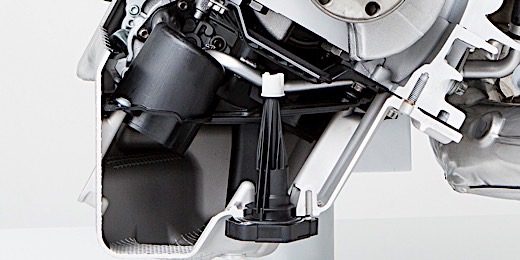

Modern oil level sensors measure the oil level differently so the oil level can be measured with the engine running. Some sensors use an electrical resistance method that works the same way as a mass airflow sensor. As less of the sensor is covered by oil, the resistive value of the sensor changes. Newer ultrasonic sensors have a piezoelectric transducer which sends ultrasonic pulses into the oil and receives echoes from the oil surface inside the sensor’s body.

This information is sent to the ECU and data like engine speed, temperature and even vehicle attitude from the ABS system is used to determine the dynamic oil level.

The ECU can then alert the driver to add more oil if the level is low. On some applications, the ECU can put the engine into a restricted power mode or not allow the engine to start if the oil level is too low.