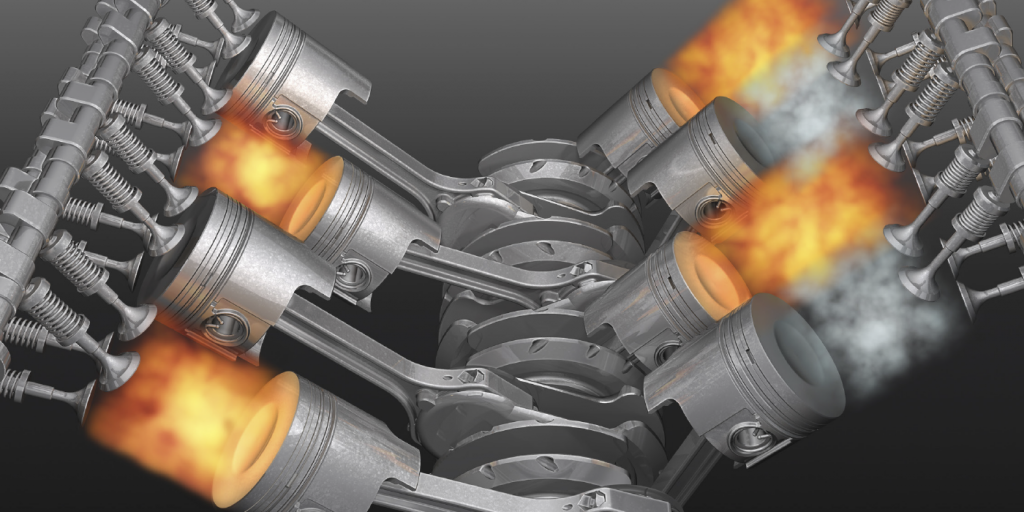

A flashing check engine light and a P0301 to P0312 diagnostic trouble code (DTC) is a surefire indication that one or more cylinders are misfiring. Occasional misfires may pass unnoticed, but a steady misfire is hard to miss. The engine usually feels rough, lacks power and uses more gas than usual. Sometimes a misfire may feel like a vibration. A misfire also will cause a huge increase in hydrocarbon (HC) emissions, which can cause a vehicle to fail an emissions test.

Misfire codes do not always indicate there is an issue with the ignition system. A misfire code is set when the computer detects a situation where there is an unexpected change in crankshaft speed.

With most engines, the crank sensor is the key component in determining a misfire. The PCM calculates the time between the edges of the crank reluctor wheel teeth by receiving a signal from the CKP sensor. The crankshaft rotational velocity and acceleration are compared in the event of a power loss from each cylinder.

When a power loss is less than the calibrated value, the suspected cylinder is determined to be misfiring by the PCM. The misfire detection is enabled after certain base information is received by the PCM. Typically, the engine coolant temperature, cylinder head temperature, intake air temperature and, if equipped, the mass air flow sensor (or a combination of these) are used to evaluate the condition as well as the crank and cam positions.

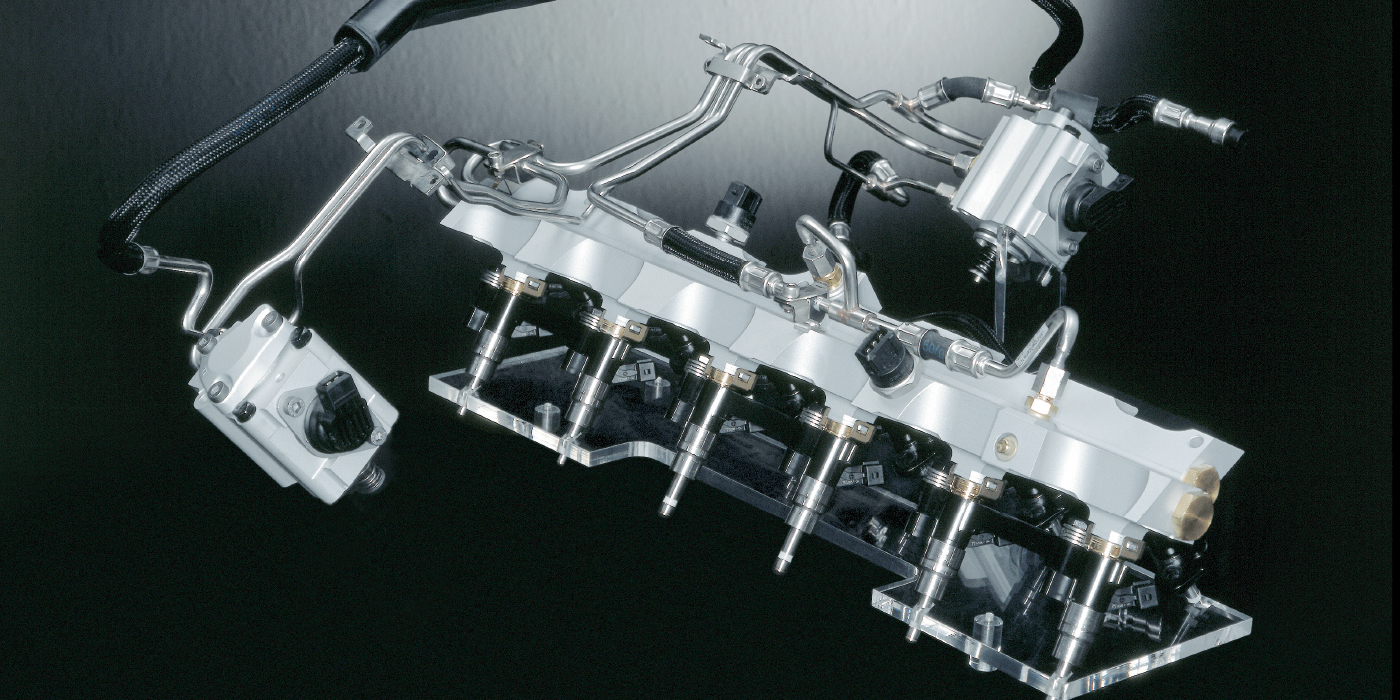

Misfires that turn on the check engine light and log a cylinder-specific fault code are the easiest to diagnose. The OBD II system will identify the cylinder(s) that are not contributing their normal dose of power and set a code that corresponds to the firing order. A P0303 code, for example, would tell you that the No. 3 cylinder is misfiring. To figure out which cylinder is No. 3, refer to a diagram of the engine’s firing order or look for markings on the intake manifold, spark plug wires or ignition coils (if the engine has a coil-on-plug ignition system).

When you have a misfire code for a particular cylinder, you can focus on one of three things: an ignition problem, a fuel injector problem or a compression problem.

WORN SPARK PLUGS

Every time a spark plug fires, the spark burns a few molecules of metal off the plug’s electrodes. Over time, this eats away the electrodes and rounds off their sharp edges. The erosion gradually increases the gap between the electrodes, which, in turn, increases the firing voltage required to generate a spark. Eventually the ignition system reaches a point where it fails to produce enough voltage and the plug misfires.

BAD SPARK PLUG WIRES

Bad spark plug wires are another common cause of misfires. After 50,000 miles or so, OEM carbon-core ignition wires develop too much internal resistance, which weakens the spark and increases the risk of misfire. High-mileage plug wires also can develop cracks that leak current to ground or to other wires, shorting the spark before it can reach the plug. Inspect the wires closely and measure their resistance. Replace any wires that are worn, damaged, do not fit properly or have resistance that exceeds specifications. If more than one plug wire is bad, replace the entire set.

WEAK FUEL INJECTOR

A condition known as “lean misfire” can occur if there is not enough fuel in the combustion chamber. Lean misfire causes that only affect one cylinder include a dirty fuel injector, an open or shorted fuel injector, or a problem in the fuel injector driver circuit (wiring or PCM). Compression problems that may cause a misfire include a burned exhaust valve, bent intake or exhaust valve, or leaky head gasket.

LEAKING FUEL INJECTOR

An individual cylinder with a rich fuel mixture is not as common as a lean mixture, but it can occur if the fuel injector leaks.

A more common condition would be a rich mixture in all cylinders caused by 1) a dead oxygen or coolant sensor that prevents the computer from going into a closed loop, or 2) a faulty fuel pressure regulator or plugged fuel return line that is routing too much pressure to the injectors.

Something else to look at in the spark burn line is the amount of “hash” it contains. A good cylinder will show a relatively clean line with little hash. A lot of hash, on the other hand, is a product of an ignition or lean misfire.

VACUUM LEAK

A vacuum leak into the intake port of the cylinder in question can cause a lack of fuel. Vacuum leaks on individual cylinders commonly occur around intake port gaskets or vacuum hose connections. Insufficient valve lash, a broken piston ring or a leaking cylinder head gasket can cause a partial loss of compression.

Depending on where the vacuum leak is on the manifold, it can generate random or specific cylinder misfire codes.

FLASH OVER OR CARBON TRACKING

The most common failure in COP ignitions is carbon tracking or “flash over” on the spark plug insulator. Although carbon tracking is usually caused by oil, dirt or moisture creating a path to ground over the spark plug insulator, a severely eroded spark plug electrode will increase firing voltages so much that the spark will seek the point of least resistance, which is either through the spark plug boot or down the insulator to the metal shell. If a carbon track is found on a spark plug, an identical track will be found inside the spark plug boot.

If the boot is serviced as a replacement part separate from the coil, the boots should be replaced at the same intervals as the spark plugs. If the boot is available only with the coil assembly, the spark plugs should be replaced at the recommended intervals and care should be taken not to contaminate the boot or insulator with dirt or oil.